Laser vibration deposition device and laser vibration deposition method under condition of integral heat insulation

A technology of cladding and conditioning, applied in the field of laser surface modification, to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

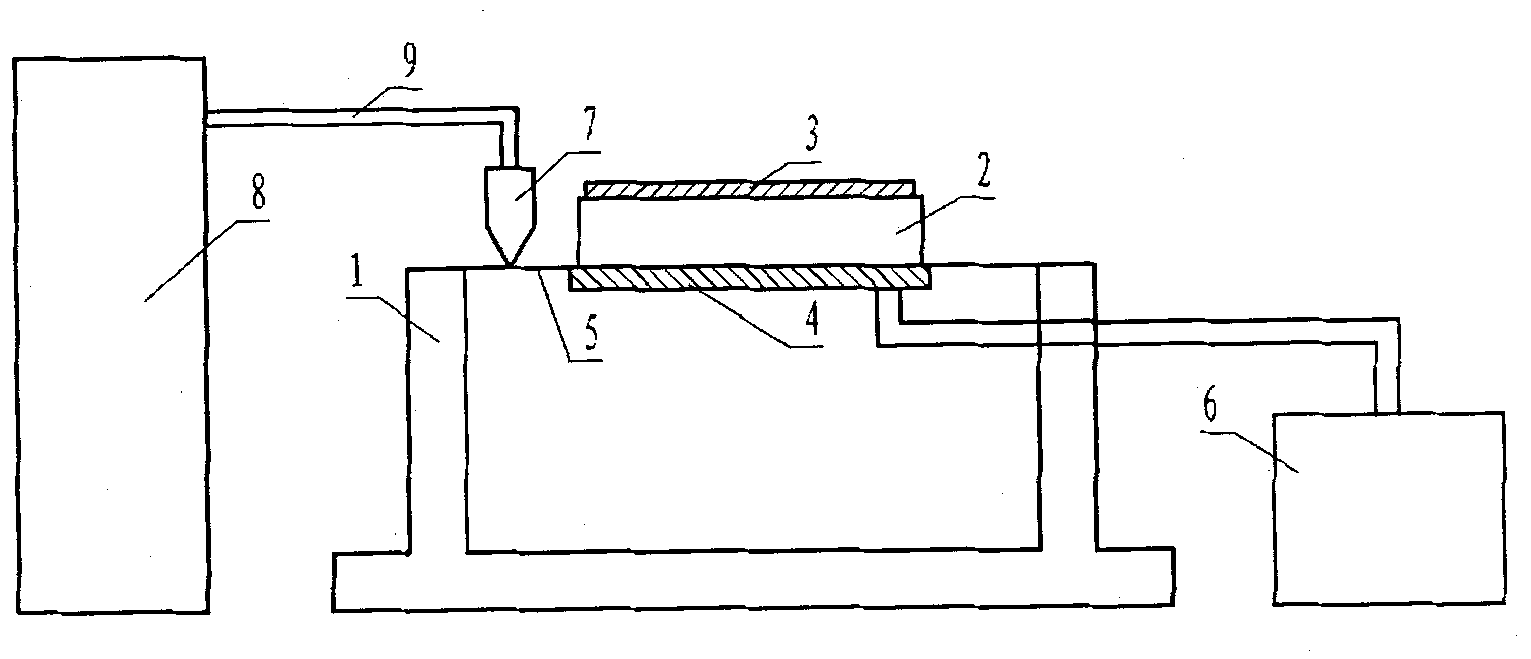

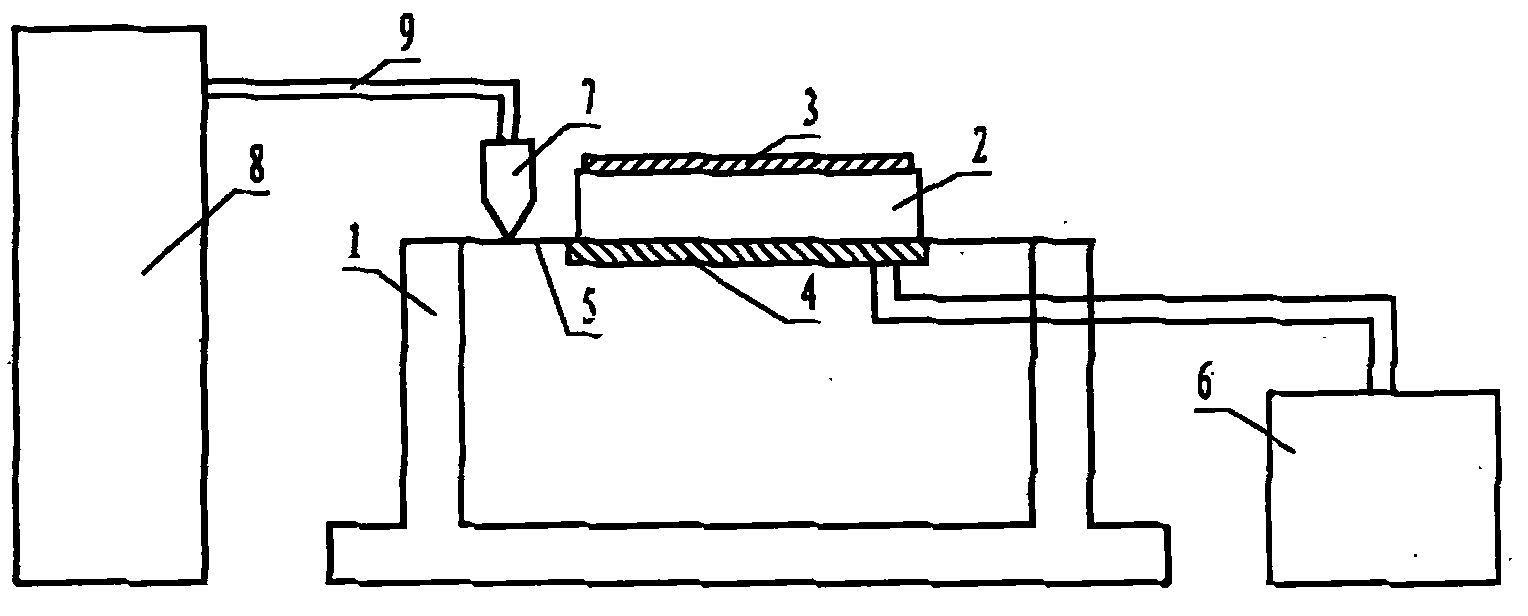

Image

Examples

Embodiment 1

[0027] The method for applying the above-mentioned device to laser vibration cladding under the condition of overall heat preservation comprises the following steps:

[0028] Step 1. Mix aluminum powder with a particle size of 200 mesh and rosin alcohol solution. The rosin alcohol solution is 5g of rosin for every 50ml of alcohol, and 3ml of rosin alcohol solution is added for every 10g of aluminum powder; spread the mixture evenly on the surface of the AZ31B magnesium alloy plate and Drying; smear about 2mm thick to form the powder to be welded 3. The size of the AZ31B magnesium alloy plate can be selected as follows: length 150mm, width 70mm, thickness 10mm.

[0029] Step 2, clamping the AZ31B magnesium alloy plate coated with the powder 3 to be deposited on the vibrating workbench;

[0030] Step 3: Arrange a temperature-controlled heating belt 4 under the AZ31B magnesium alloy plate, and use a temperature controller 6 to keep the entire workpiece within a temperature range...

Embodiment 2

[0037] Step 1. Mix nickel powder with a particle size of 100 mesh and rosin alcohol solution (50ml alcohol plus 5g rosin, add 1ml rosin alcohol solution for every 10g nickel powder; apply the mixture evenly on the surface of No. 45 steel plate and dry it; smear about 2mm Thickness; the size of No. 45 steel plate is 150mm long, 70mm wide and 10mm thick.

[0038] Step 2, clamping the No. 45 steel plate coated with the mixture of nickel powder and rosin alcohol solution on the vibrating workbench;

[0039] Step 3. Arrange a temperature-controlled heating belt under the No. 45 steel plate, and make the entire workpiece within the range of 300°C ± 20°C through the temperature control system;

[0040] Step 4. Start the vibration generator to drive the workpiece to vibrate through the vibration head, and the vibration frequency is 50Hz;

[0041] Step 5. Use a 5000W CO2 laser to scan at a speed of 1200mm / min, under argon protection, with a lap rate of 50%, and perform laser cladding ...

Embodiment 3

[0045]Step 1. Mix copper powder with a particle size of 200 mesh and rosin alcohol solution (50ml alcohol plus 5g rosin), wherein 1ml rosin alcohol solution is added for every 5g copper powder; apply the mixture evenly on the surface of No. 45 steel plate and dry it; About 2mm thick; the size of the No. 45 steel plate is 150mm long, 70mm wide and 10mm thick.

[0046] Step 2, clamping the No. 45 steel plate coated with the mixture of copper powder and rosin alcohol solution on the vibration table;

[0047] Step 3. Arrange a temperature-controlled heating belt under the No. 45 steel plate, and make the entire workpiece within the range of 400°C ± 20°C through the temperature control system;

[0048] Step 4. Start the vibration generator to drive the workpiece to vibrate through the vibration head, and the vibration frequency is 50Hz;

[0049] Step 5. Use 5000W CO 2 The laser scans at a speed of 900mm / min, protected by argon, with a lap rate of 40%, and performs laser cladding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com