Fireproof flame-retardant silicon rubber

A fire retardant and silicone rubber technology, applied in the field of rubber products, can solve the problems of the loss of protective effect of the flame retardant silicone rubber protective layer, potential safety hazards, etc., and achieve the effect of preventing direct exposure to high temperature and combustion environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 300 parts of raw silicone rubber, 50 parts of reinforcing filler, 20 parts of anti-structuring additive, 60 parts of aluminum powder, 3 parts of release agent, 35 parts of special filler, and 5 parts of vulcanizing agent.

Embodiment 2

[0021] 300 parts of raw silicone rubber, 50 parts of reinforcing filler, 20 parts of anti-structuring additive, 55 parts of aluminum powder, 3 parts of release agent, 40 parts of special filler, and 5 parts of vulcanizing agent.

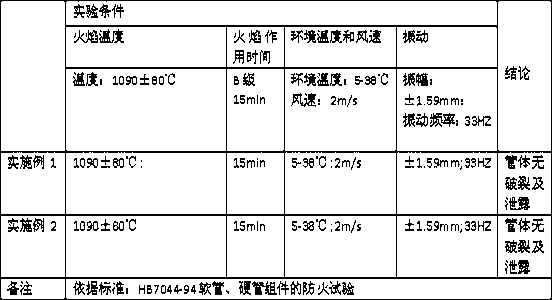

[0022] Adopt embodiment 1 and be the fireproof flame retardant silicone rubber that embodiment 2 makes, its fireproof flame retardant performance is as follows:

[0023]

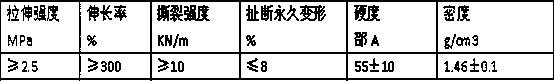

[0024] The properties of the prepared compound are shown in the table below:

[0025]

[0026] The difference between the above examples 1 and 2 is only that the content of special fillers and aluminum powder is different. At a temperature of 1090±80°C, there is a ceramic-like structure covering the surface of the silicone rubber, which can play a very good flame-retardant effect.

Embodiment 3

[0028] 300 parts of raw silicone rubber, 30 parts of reinforcing filler, 15 parts of anti-structuring additive, 40 parts of aluminum powder, 3 parts of release agent, 10 parts of special filler, 4 parts of vulcanizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com