Device and method used for recycling hydrogen from chlor-alkali industry vented tail gas and preparing high purity hydrogen

A technology for the chlor-alkali industry and high-purity hydrogen, which is applied in the development and application of vent gas in the chlor-alkali industry, and can solve problems such as the impact on equipment operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

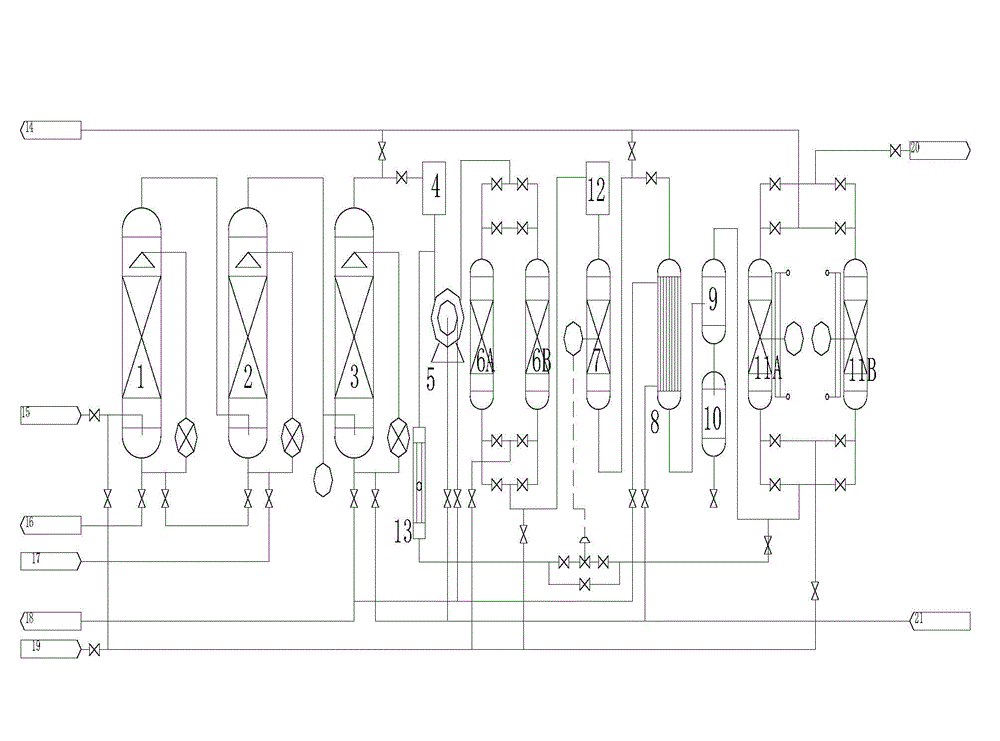

Image

Examples

Embodiment 1

[0055] (1) Chlor-alkali tail gas

[0056] Chlor-alkali tail gas volume: 500m 3 / h Temperature: 25°C Pressure: 1 atmosphere

[0057] Main components: H 2 96%, O 2 3%, Cl 2 ≥100ppm, the rest is a small amount of carbon dioxide, etc.

[0058] (2) Dechlorination agent

[0059] Use caustic soda solution NaOH concentration 2% (mass percentage);

[0060] QT-C1 high-efficiency dechlorination agent (main component: ZnO / Al 2 o 3 / CaO add accelerator, the mass ratio of each component is 40%, 40%, 20%), the use of space velocity: 3000h -1 Total loading: 0.2m 3

[0061] Fine dechlorination tower aspect ratio: 5

[0062] (3) Catalyst

[0063] Catalytic deoxidizer AC-3 type precious metal catalyst (the active component is palladium, the carrier is alumina, the active component accounts for 0.2% of the weight of the carrier)

[0064] Noble metal catalyst use space velocity: 5000h -1

[0065] The total amount of precious catalyst loaded: 0.15m 3

[0066] Catalytic deoxidation ...

Embodiment 2

[0072] (1) Chlor-alkali tail gas

[0073] Chlor-alkali tail gas volume: 1500m 3 / h Temperature: 25°C Pressure: 1 atmosphere

[0074] Main components: H 2 97%, O 2 2%, Cl 2 ≤30ppm, the rest is a small amount of carbon dioxide, etc.

[0075] (2) Dechlorination agent

[0076] QT-C1 high-efficiency dechlorination agent (main component: ZnO / Al 2 o 3 / CaO adds promotor, the same embodiment 1), using space velocity: 3000h -1 Total loading: 0.6m 3

[0077] Fine dechlorination tower aspect ratio: 8

[0078] (3) Catalyst (same as above embodiment 1) noble metal catalyst use space velocity: 5000h -1

[0079] The total amount of precious catalyst loaded: 0.5m 3

[0080] Catalytic deoxidation tower aspect ratio: 6

[0081] (4) steps

[0082] Chlor-alkali tail gas hydrogen (1500m 3 / h) (wherein the chlorine content is less than or equal to 30ppm, and the oxygen content is 2%), the atmospheric pressure hydrogen is pressurized to about 0.03Mpa through the water ring compresso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com