Flame-retardant moisture-absorbing fabric and preparation method thereof

A fabric and soluble technology, applied in the direction of flame-retardant fibers, fiber types, textiles, and papermaking, can solve problems such as poor compatibility, unfavorable fiber forming, and poor flame-retardant stability of modified fibers, so as to increase surface energy, The effect of improving moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

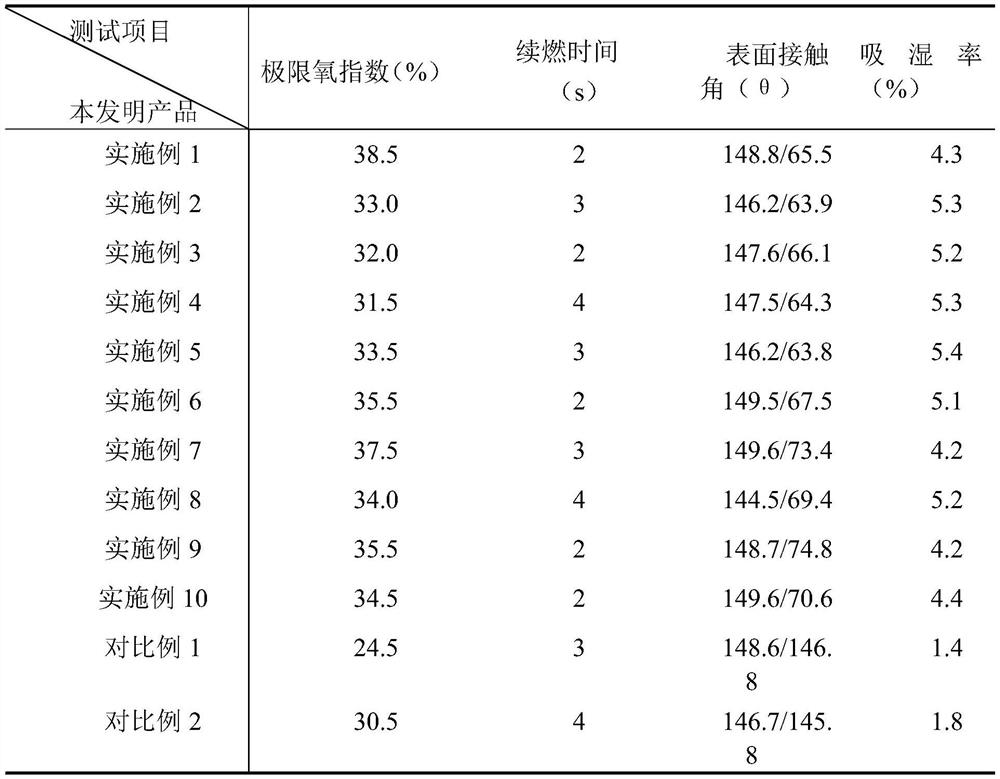

Examples

Embodiment 1

[0029] In 50mL deionized water, add 0.25g CuSO 4 , 0.7g MgSO 4 , 0.4g Al 2 (SO 4 ) 3 and 2.6g of urea, fully dissolved, transferred to a hydrothermal kettle, and placed in an oven for crystallization at 100°C for 12h. After the reaction was completed, it was taken out after cooling down to room temperature, centrifuged and washed several times with deionized water, and finally vacuum-dried for 12 hours to obtain a layered double metal hydroxide.

[0030] Put 2 g / L layered double metal hydroxide in 2 g / L tris hydroxymethylaminomethane (Tris) buffer solution and sonicate for 6 hours to obtain a uniform and stable suspension system.

[0031] Put the cleaned polyester fabric into the above suspension, add 2g / L dopamine hydrochloride, vibrate at 25°C for 12 hours at a rotation speed of 200r / min, then take out the fabric and dry it in an oven to obtain the modified moisture-absorbing and flame-retardant fabric. Sexy fabrics.

Embodiment 2

[0033] In 50mL deionized water, add 1.05g CuSO 4 with 0.4gAl 2 (SO 4 ) 3 and 2.6g of urea, fully dissolved, transferred to a hydrothermal kettle, and placed in an oven for crystallization at 110°C for 24h. After the reaction was completed, it was taken out after cooling down to room temperature, washed several times by centrifugation with deionized water, and finally vacuum-dried for 24 hours to obtain a layered double metal hydroxide.

[0034] Put 3g / L layered double metal hydroxide in 1g / L phosphate buffer solution and sonicate for 3h to obtain a uniform and stable suspension system.

[0035] Arrange the cleaned cotton in the above suspension, add 1g / L dopamine hydrochloride, vibrate at 30°C for 24 hours at a speed of 100r / min, then take out the fabric and dry it in an oven to obtain the modified hygroscopic and flame retardant fabric.

Embodiment 3

[0037] In 50mL deionized water, 1gZnCl 2 with 0.3g FeCl 3 and 5mL ammonia water (concentration: 20%), fully dissolved, transferred to a hydrothermal kettle, and placed in an oven for crystallization at 110°C for 6h. After the reaction was completed, it was taken out after cooling down to room temperature, centrifuged and washed several times with deionized water, and finally vacuum-dried for 12 hours to obtain a layered double metal hydroxide.

[0038] Put 2g / L layered double metal hydroxide in 0.2g / L borate buffer solution and sonicate for 3h to get a uniform and stable suspension system.

[0039] Put the cleaned viscose fabric into the above suspension, add 0.5g / L dopamine hydrochloride, vibrate at 50°C for 6h at a speed of 300r / min, then take out the fabric and dry it in an oven to obtain the moisture absorption resistance Flammable modified fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com