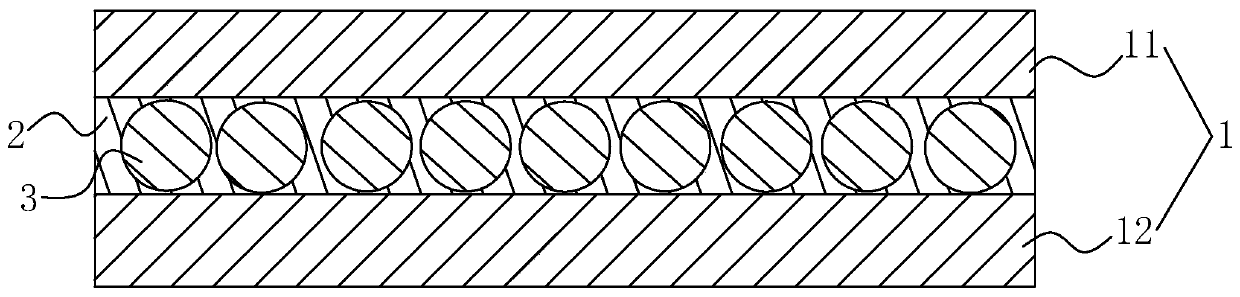

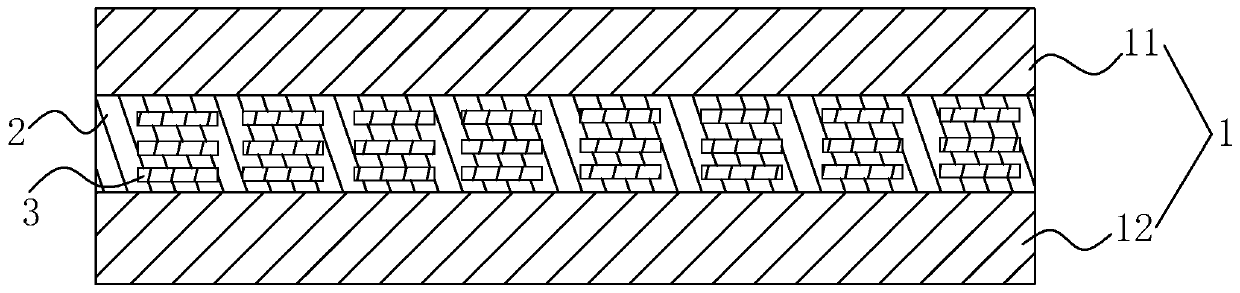

Flame-retardant high-strength conveyor belt and preparation process thereof

A conveyor belt, high-strength technology, applied in the direction of conveyors, transportation and packaging, non-polymer adhesive additives, etc., can solve the problem of inability to achieve high mechanical properties in flame retardancy, poor toughness and strength of conveyor belts, and Reinforcing ingredients and other problems, to achieve high limiting oxygen index, good softness and impact resistance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

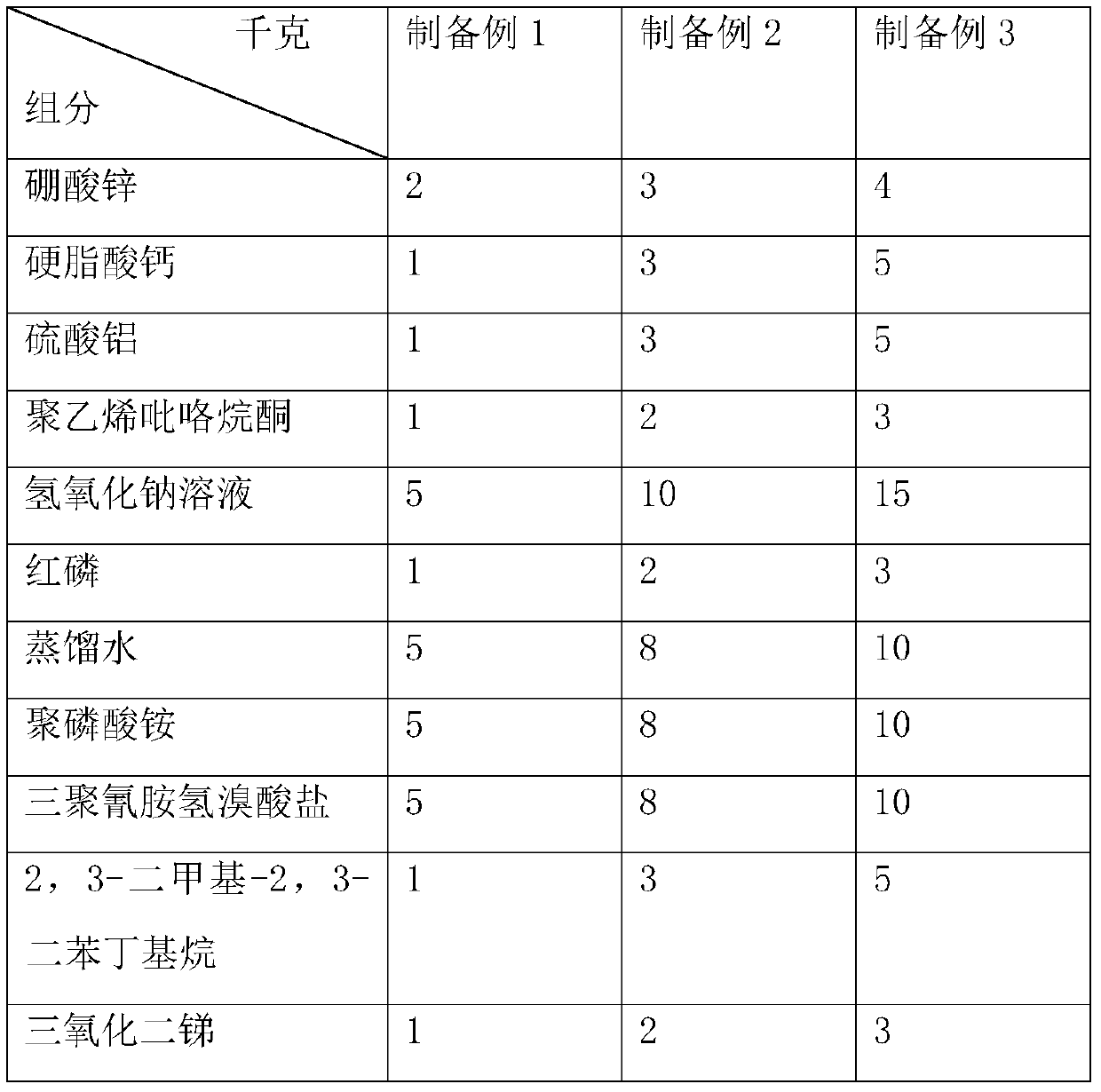

preparation example 1-3

[0058] In Preparation Examples 1-3, melamine hydrobromide was sold by Wuhan Xingzhongcheng Technology Co., Ltd., and polyvinylpyrrolidone was sold by Shanghai Baishun Biotechnology Co., Ltd.

preparation example 1

[0059] Preparation Example 1: (1) According to the proportioning in Table 1, put 5kg of melamine hydrobromide and 5kg of ammonium polyphosphate into the stirrer and stir evenly, then add 1kg2,3-dimethyl-2 to the stirrer , 3-diphenylbutylalkane and 1 kg of antimony trioxide, mixed evenly, dried in a vacuum oven, ground into powder, and the drying temperature was 60°C;

[0060] (2) Dissolve 1 kg of aluminum sulfate in 5 kg of water, add 1 kg of polyvinylpyrrolidone into the aluminum sulfate solution, perform ball milling until the diameter of the red phosphorus is 5 μm, and add 5 kg of sodium hydroxide solution with a mass fraction of 8% in the red phosphorus , adjust the pH value to 5, add 1kg of polyvinylpyrrolidone, incubate at 75°C for 1 hour, filter, wash and dry;

[0061] (3) Mix the product of step (1) and step (2) with 2kg zinc borate and 1kg calcium stearate evenly, and carry out extrusion granulation.

[0062] The raw material ratio of composite flame retardant in tab...

preparation example 2

[0064] Preparation Example 2: (1) According to the proportioning in Table 1, put 8kg of melamine hydrobromide and 8kg of ammonium polyphosphate into the agitator and stir evenly, then add 3kg2,3-dimethyl-2 to the agitator , 3-diphenylbutylalkane and 2kg of antimony trioxide, mixed evenly, dried in a vacuum drying oven, ground into powder, and the drying temperature was 70°C;

[0065] (2) 3kg aluminum sulfate is dissolved in 8kg water, 2kg red phosphorus is added in aluminum sulfate solution, carry out ball milling, be ground to red phosphorus diameter and be 8 μm, add 10kg massfraction in red phosphorus and be 8% sodium hydroxide solution, Adjust the pH value to 5.5, add 2kg of polyvinylpyrrolidone, incubate at 80°C for 1.5 hours, filter, wash and dry;

[0066] (3) Mix the product of step (1) and step (2) with 3kg zinc borate and 3kg calcium stearate evenly, and carry out extrusion granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com