System device for processing granular feed by utilizing wind energy

A technology of pellet feed and system device, applied in the fields of feed, application, food science, etc., can solve the problem of consuming large power and energy, and achieve the effect of strong function, large crushing capacity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

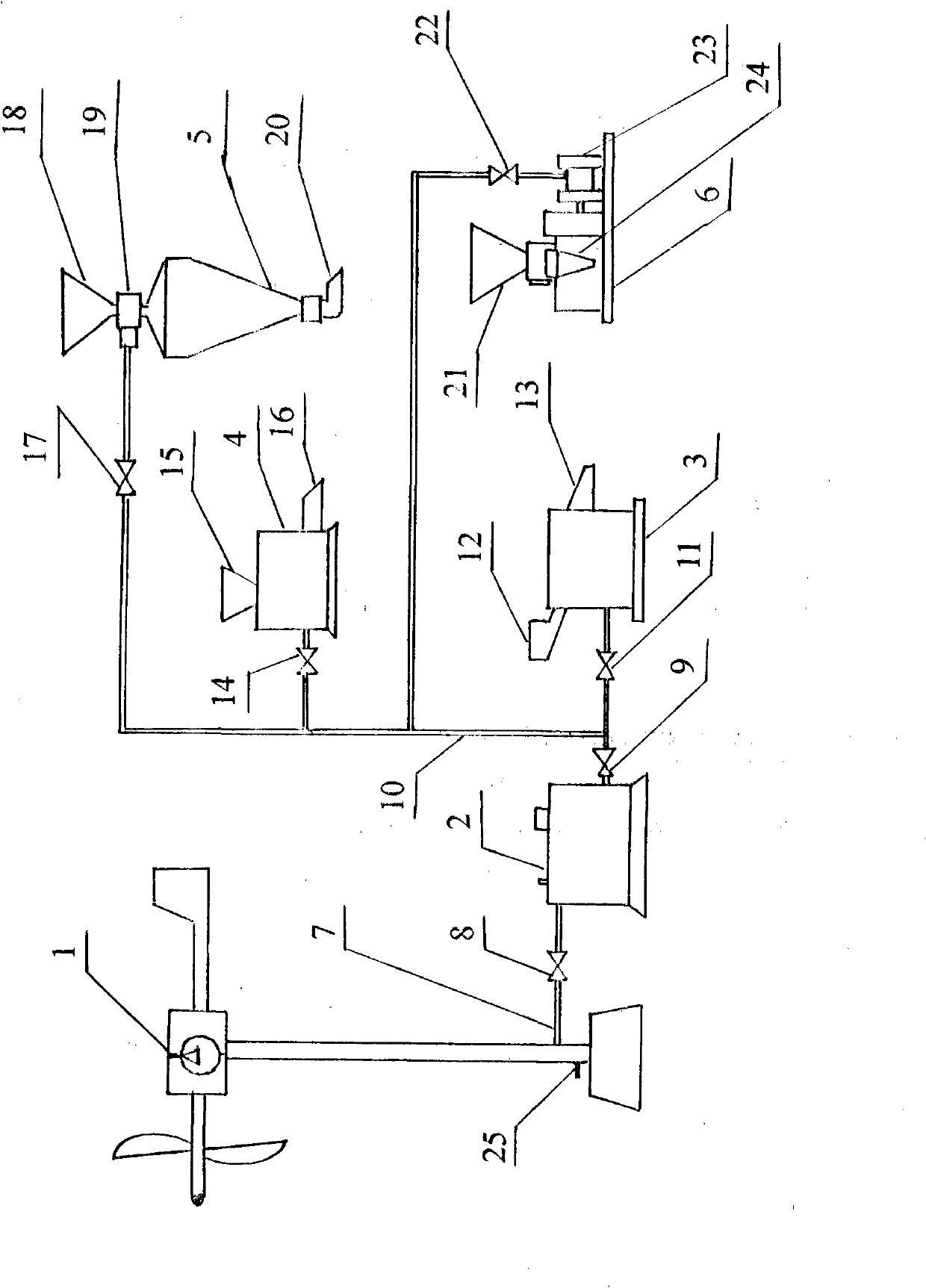

Image

Examples

Embodiment Construction

[0020] a. Air compressor installation: set up a wind-powered air compressor 1 at the ventilated place, and a vent valve 25 is provided at the bottom of the lower rod of the compressor to release the remaining compressed air in the rod, and a pneumatic valve 8 is set on the pipeline 7 for Controlling the output of compressed gas;

[0021] b. Install a supercharger: set and install the GBM gas supercharger 2, which is connected with the pneumatic valve 8 on the output pipe 7 of the wind power air compressor, and uses compressed air as power to supercharge the compressed air produced by the wind power compressor 1, The increased air medium can be boosted twice or five times, and has the function of stable pressure output. The output pressure value can be adjusted to the pressure range allowed by the working place through the additional pressure reducing valve 9. After boosting The pressure of the generated high-pressure air source can reach 7-8 kg / cm2;

[0022] c. Pneumatic pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com