Device used for super high speed centrifugal test of composite material

A technology of ultra-high-speed centrifugation and test device, applied in the field of centrifugal test, can solve the problems of low test lift rate, large blowing power loss of the test piece, long test time, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A device for ultrahigh-speed centrifugation testing of composite materials provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

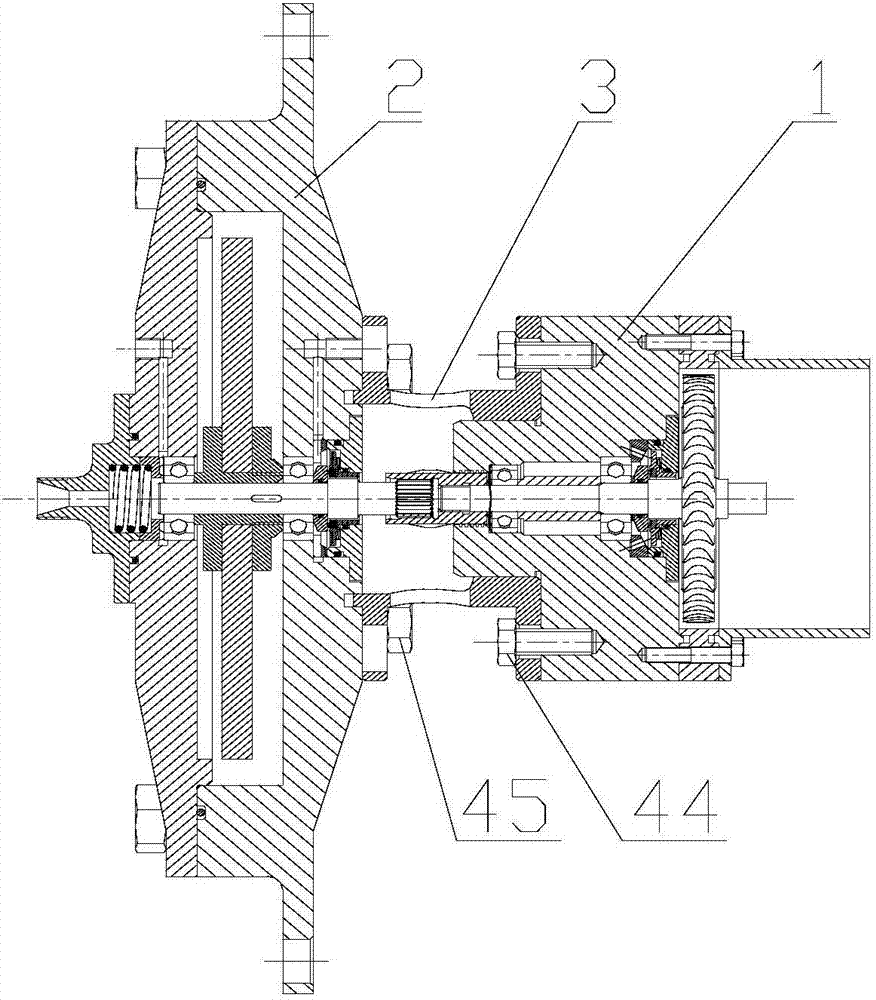

[0043] Such as figure 1 As shown, the present invention provides an ultrahigh-speed centrifugal test device for composite materials, including a turbine drive part 1, a tested test part 2 and a positioning connection part 3; the turbine drive part 1 and the positioning connection part 3 are fixedly connected by screws 44 , the positioning connection part 3 and the tested part 2 are fixedly connected by screws 45 .

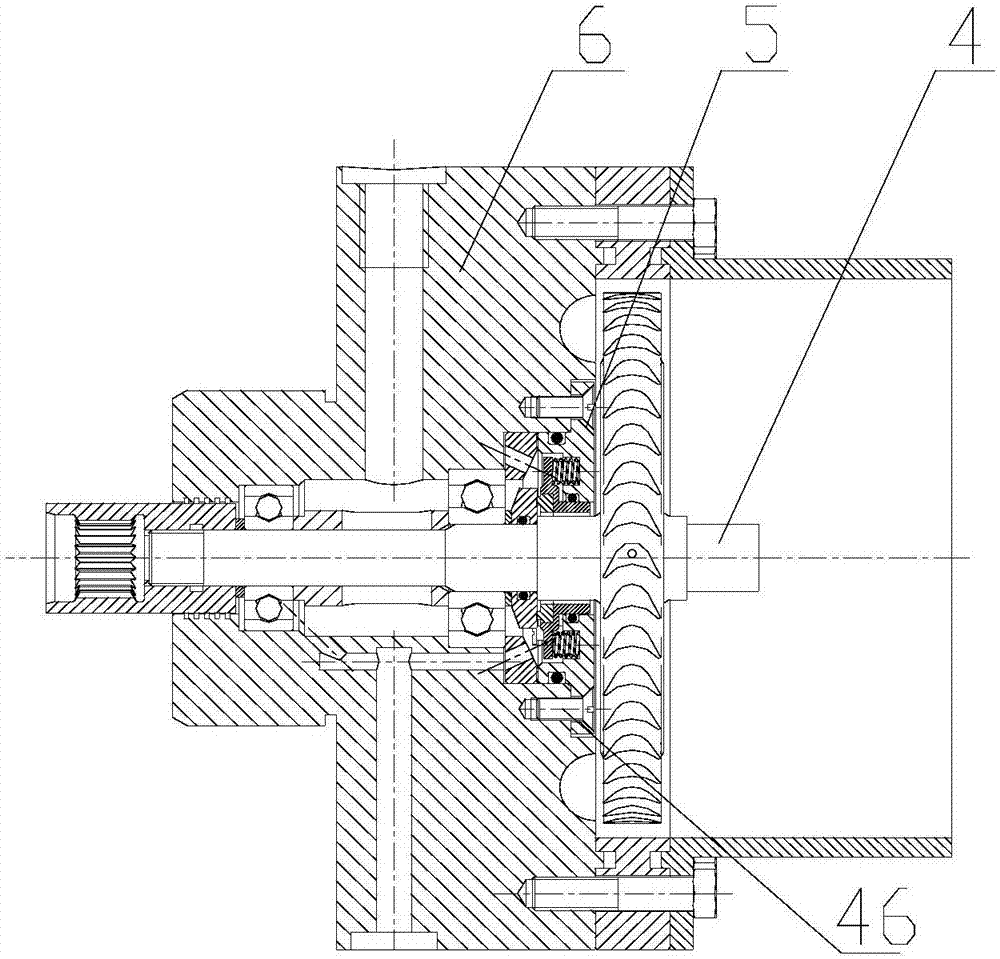

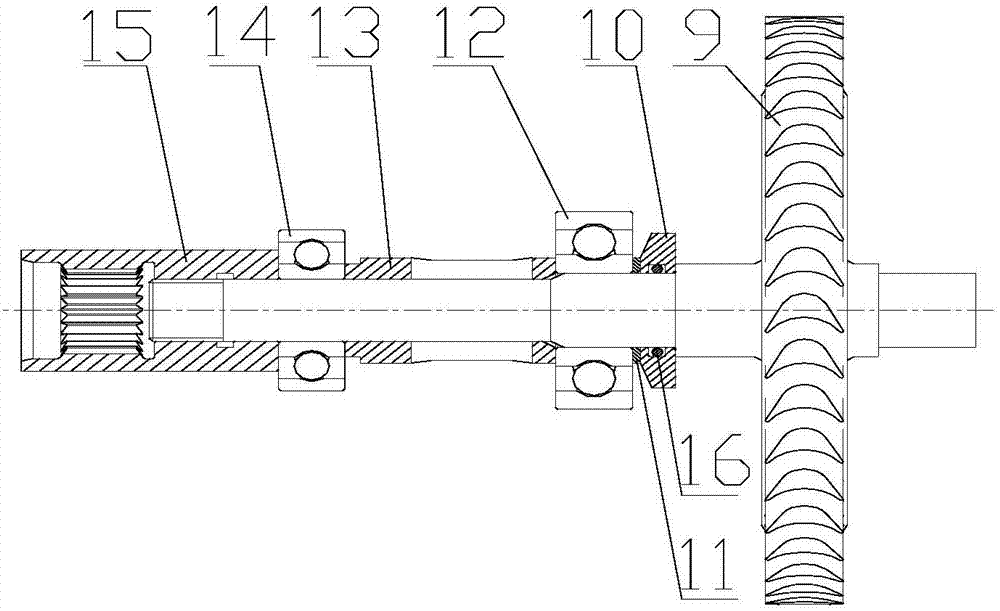

[0044] Such as figure 2 As shown, the turbine driving part 1 includes a turbine shaft assembly 4, a mechanical dynamic seal assembly 5 and a housing assembly 6; the mechanical dynamic seal assembly 5 is fixedly installed inside the housing assembly 6 by screws 46, and the mechanical dynamic seal assembly 5 is sleeved on On the shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com