The pre-treatment process of cotton woven fabrics and the formula of desizing working solution

A technology for working fluids and fabrics, applied in physical treatment, fiber treatment, biochemical fiber treatment, etc., can solve problems such as consumption, pollution, waste of water resources and water environment, and achieve the effect of reducing damage and improving desizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

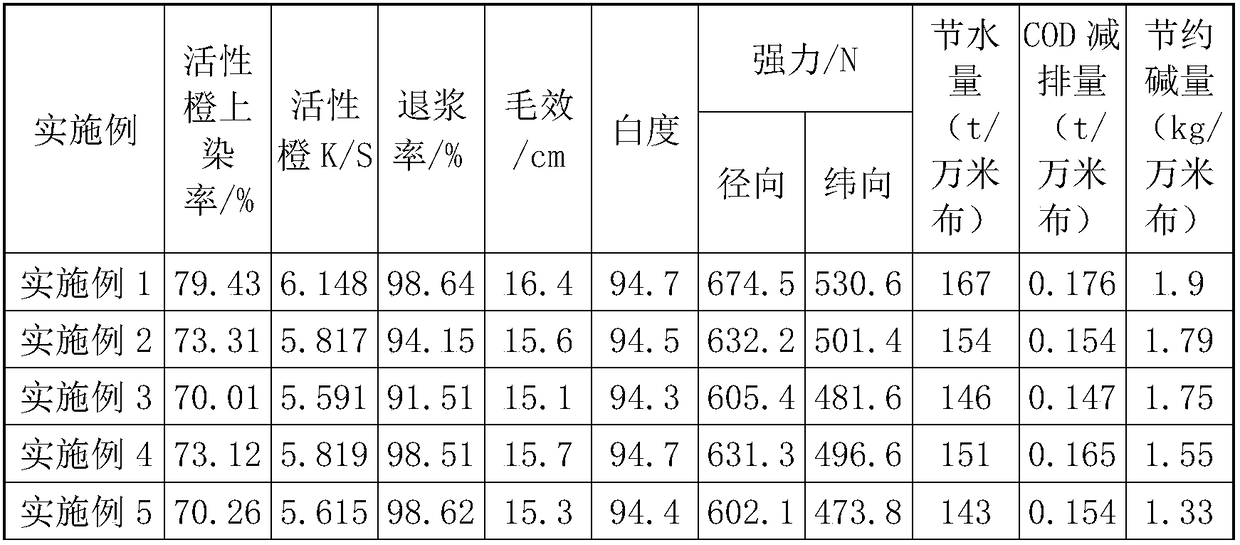

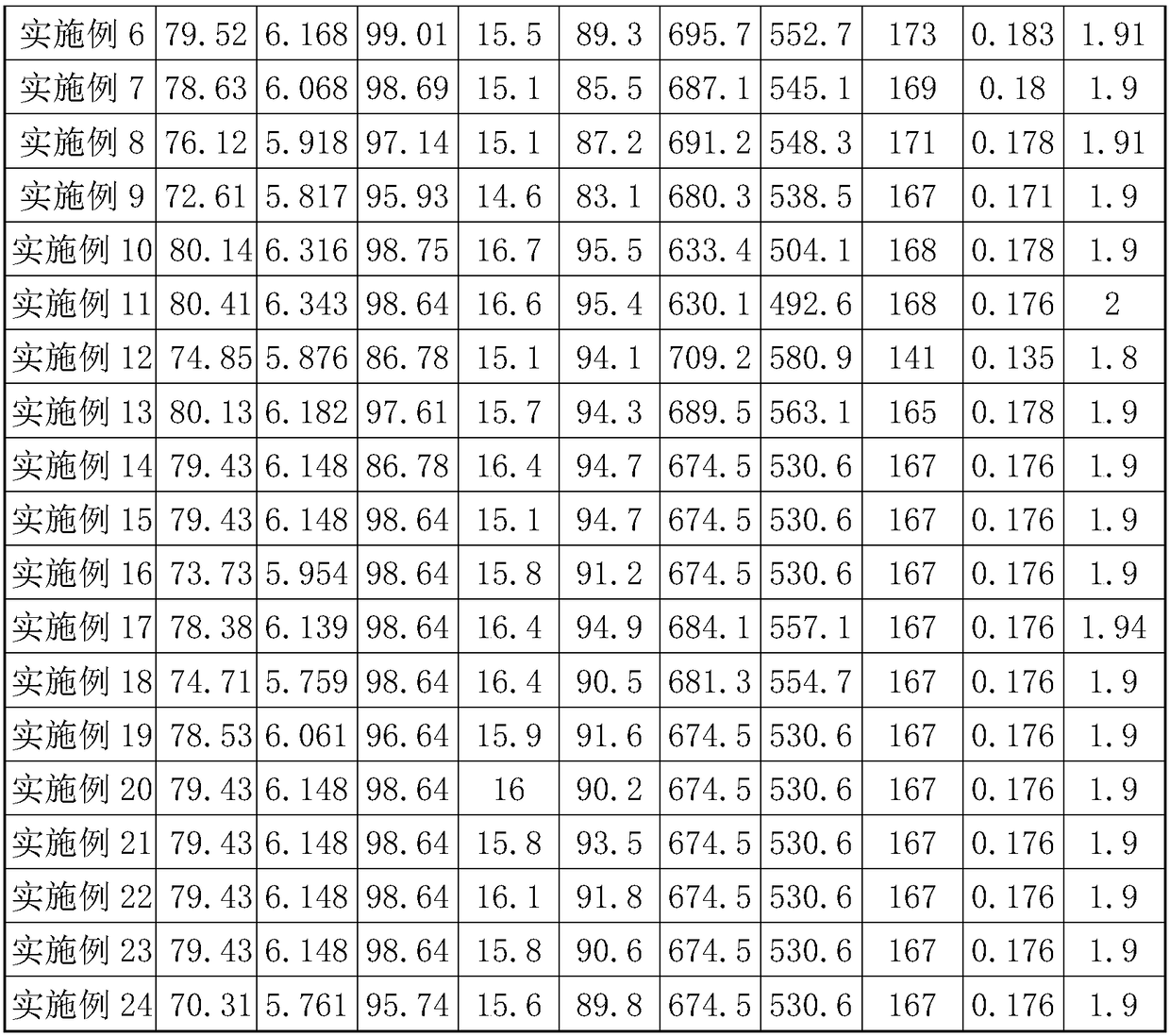

Examples

Embodiment 1

[0060] Embodiment 1: a kind of printing and dyeing pretreatment process of cotton woven fabric, comprises the following steps:

[0061] S1, singeing. After the cloth is brushed, it passes through the gas singeing machine at a speed of 60-150m / min. The flame temperature of the gas singeing machine is 800-900°C. The speed depends on the thickness of the cloth. The thicker the cloth, the slower the speed. The specific speed and flame temperature are checked after singeing to see whether the fluff is burned cleanly and does not affect the fabric body. In this embodiment, the speed is 100m / min, and the flame temperature is 950°C;

[0062] S2, desizing, including 6 stages of rinsing with decreasing concentration of the working solution, followed by 1 stage rinsing, 2 stage rinsing, 3 stage rinsing, 4 stage rinsing, 5 stage rinsing and 6 stage rinsing. The concentration of the working solution is the highest, the concentration of the working solution for the second rinse is 80% of th...

Embodiment 2

[0081] Example 2: The difference from Example 1 is that the desizing step of S2 includes 4 stages of rinsing, followed by 1 stage rinsing, 2 stage rinsing, 3 stage rinsing and 4 stage rinsing, wherein, in the 1 stage rinsing The concentration of the working solution is the highest, the concentration of the working solution for the second rinse is 60% of the concentration of the working solution in the first rinse, the concentration of the working solution for the third rinse is 30% of the concentration of the working solution in the first rinse, and the concentration of the working solution for the fourth rinse The solution concentration is 10% of the working solution concentration in the first-level rinse, the working solution concentration in the fifth-level rinse is 20% of the working solution concentration in the first-level rinse, and the working solution concentration in the sixth-level rinse is the smallest and equal to the first-level rinse. 10% of the working solution ...

Embodiment 3

[0082] Example 3: The difference from Example 1 is that the desizing step of S2 includes 2-stage rinsing, followed by 1-stage rinsing and 2-stage rinsing, wherein the concentration of the working solution in the 1-stage rinsing is the largest, and the 2-stage rinsing The concentration of the working solution is 50% of the concentration of the working solution in the first-level rinse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com