Friction pendulum connected fabricated steel structure system and design method thereof

A technology of friction pendulum and steel structure, applied in calculation, building components, building structure, etc., can solve problems such as heavy on-site workload, poor seismic performance of the frame, and complicated connection nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

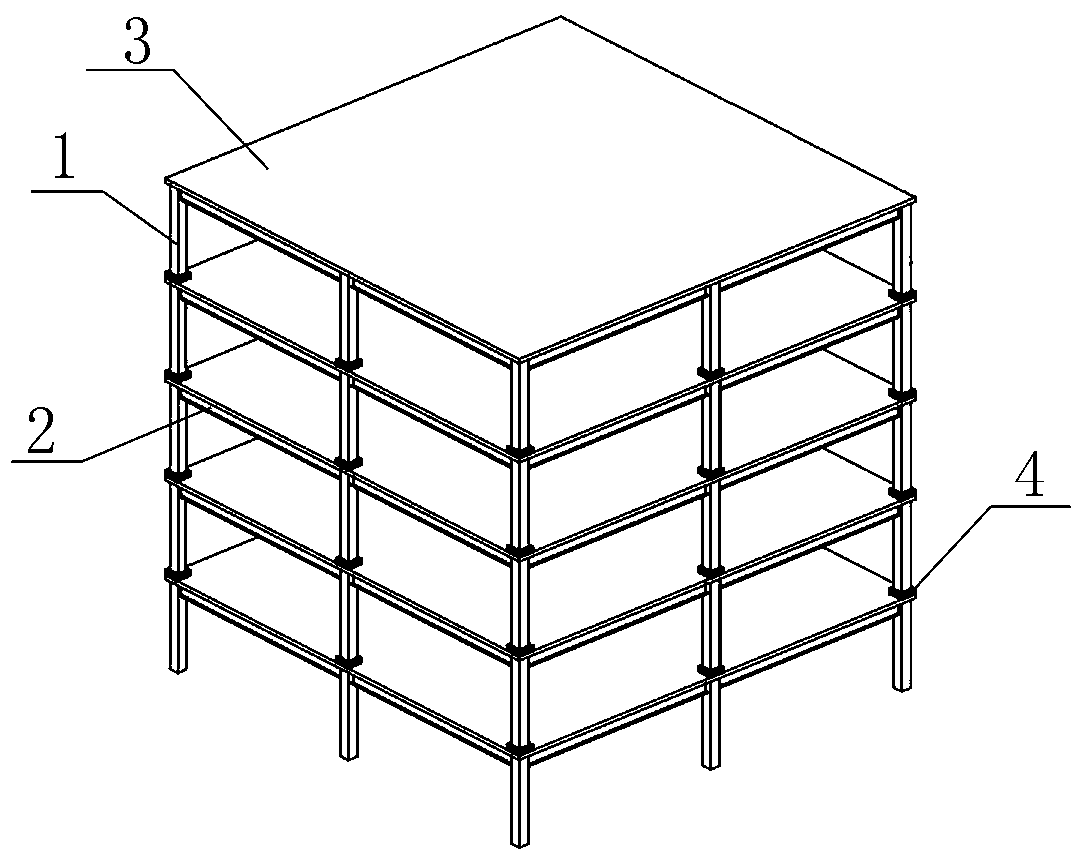

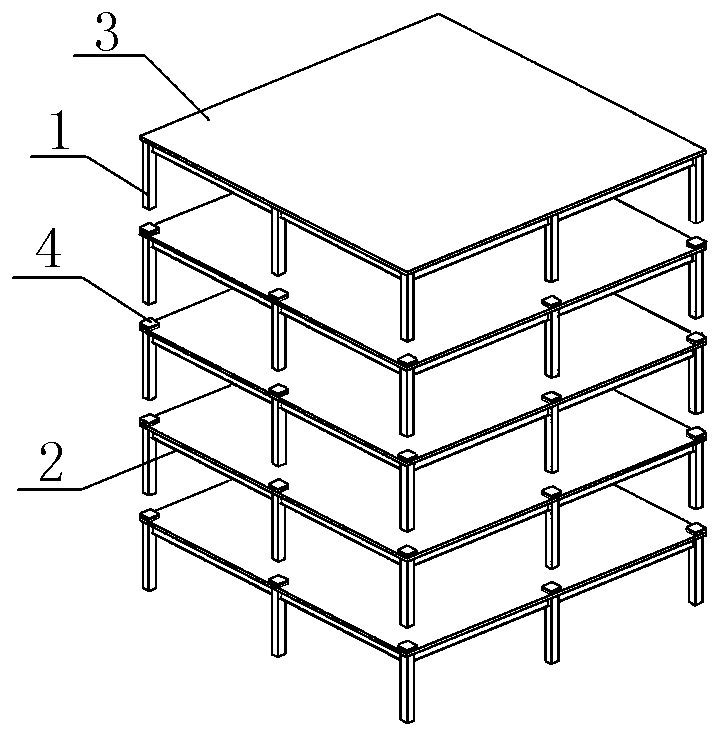

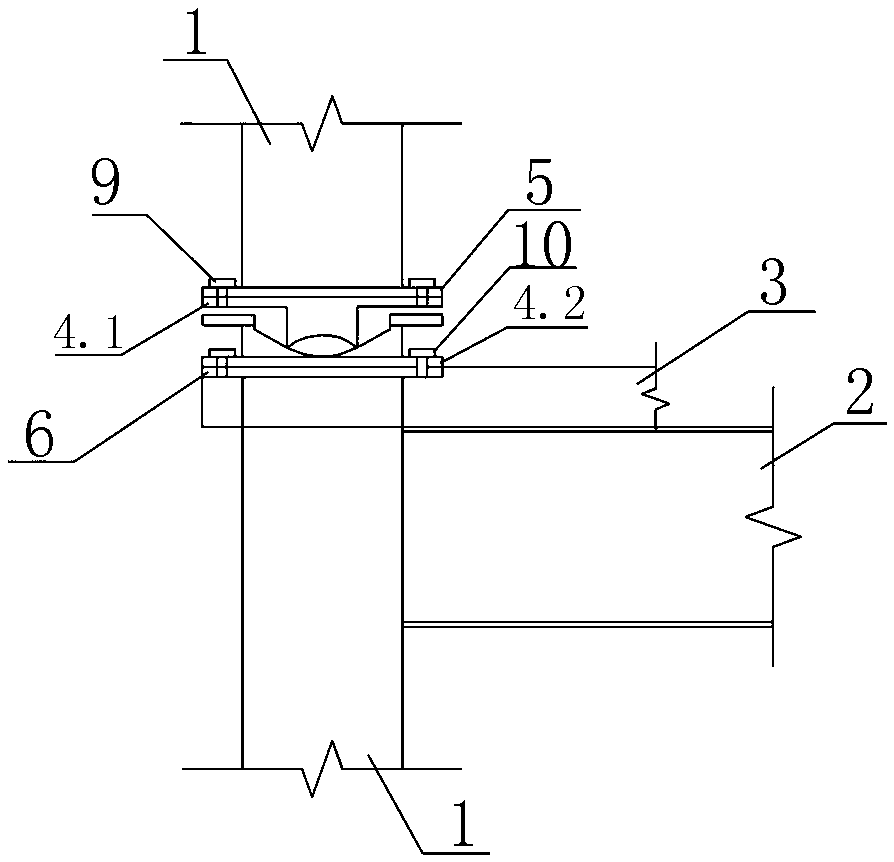

[0085] Such as Figure 1-7 As shown, this prefabricated steel structure system connected by friction pendulum includes at least two layers of steel frame structures stacked vertically; multiple identical steel frame structures are assembled up and down; each layer of steel frame structures includes There are steel columns 1, steel beams 2, and floor slabs 3; among them, there is a group of steel columns 1 arranged at intervals along the horizontal and vertical intervals of the steel frame structure; there is a group of steel beams 2, which are respectively connected to the tops of horizontally adjacent steel columns 1 Between and between the tops of vertically adjacent steel columns 1; the floor 3 is set on the top of a group of steel beams 2; the steel columns 1 of each steel frame structure are disconnected at the connection with the floor 3 of the lower floor, and the adjacent The two-story steel frame structure is connected by a friction pendulum shock-isolation device 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com