Ordered carbon nano-tube reinforced aluminum matrix composite material and preparation method thereof

A technology for reinforcing aluminum matrix and composite materials, which is applied in the field of ordered carbon nanotube reinforced aluminum matrix composite materials and its preparation, can solve the problems of disordered distribution of carbon nanotubes, etc., and achieves control of high temperature interface reaction, short high temperature residence time, Process efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

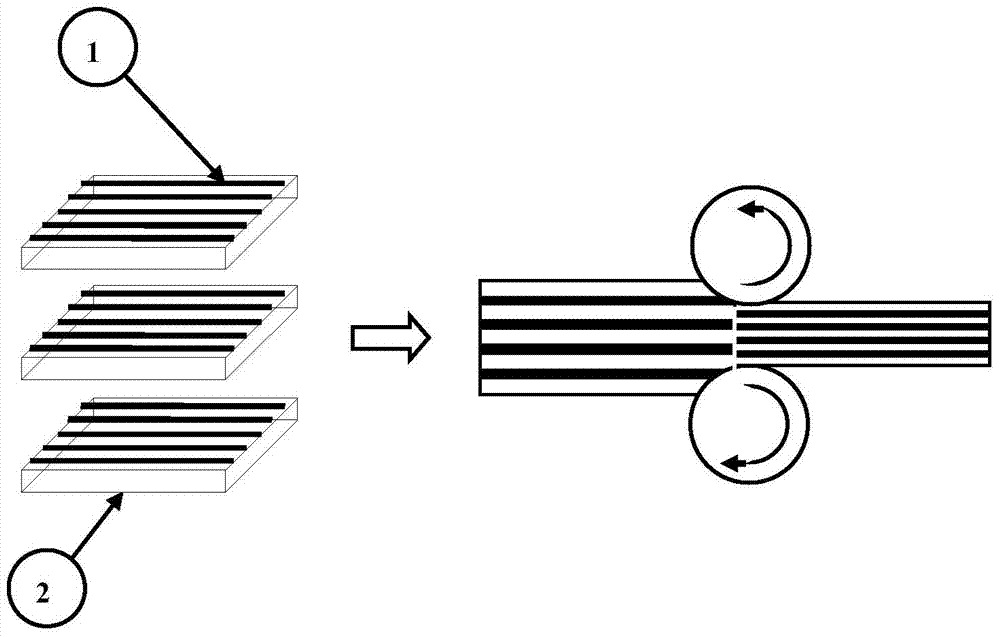

[0028] Another aspect of the present invention aims to provide a method for preparing an ordered carbon nanotube-reinforced aluminum-based composite material, comprising: laminating a plurality of ordered carbon nanotube film layers and a plurality of aluminum or its alloy layers and then hot rolling to form a composite material. The ordered carbon nanotube reinforced aluminum-based composite material.

[0029] As one of the practicable solutions, the method may include: preparing a spinnable carbon nanotube array using chemical vapor deposition technology, and directly preparing a super-sequential carbon nanotube film through the array drawing technology; and then laying it on the surface of the aluminum foil, After many times of lamination, it is vacuum sealed in the sheathing material; finally, it is preheated to a certain temperature, and a dense billet is prepared by multiple hot rolling, and then the sheathing material is removed by machining to obtain the target material.

...

Embodiment 1

[0042] Example 1 See figure 1 , The preparation method of the carbon nanotube reinforced aluminum-based composite material is realized as follows:

[0043] Step 1: Use electron beam evaporation to deposit an alumina transition layer on the silicon wafer substrate, then deposit Fe, Co or Fe / Co composite film as a carbon nanotube array growth catalyst, and then use chemical vapor deposition in a tube furnace to prepare spinnable Silk carbon nanotube array; and then obtain super-in-line carbon nanotube film through solid-phase drawing technology;

[0044] Step 2: Lay the super-aligned carbon nanotube film 1 on the surface of a pure aluminum foil 2 with a thickness of 0.03mm, stack them several times, and cut them into a sample with a size of 15mm×20mm;

[0045] Step 3: Vacuum seal the sample in a copper tube with an outer diameter of 25mm, a wall thickness of 0.5mm, and a length of 30mm. The carbon nanotube film and aluminum foil are laminated in 7 layers. When the relative reduction ...

Embodiment 2

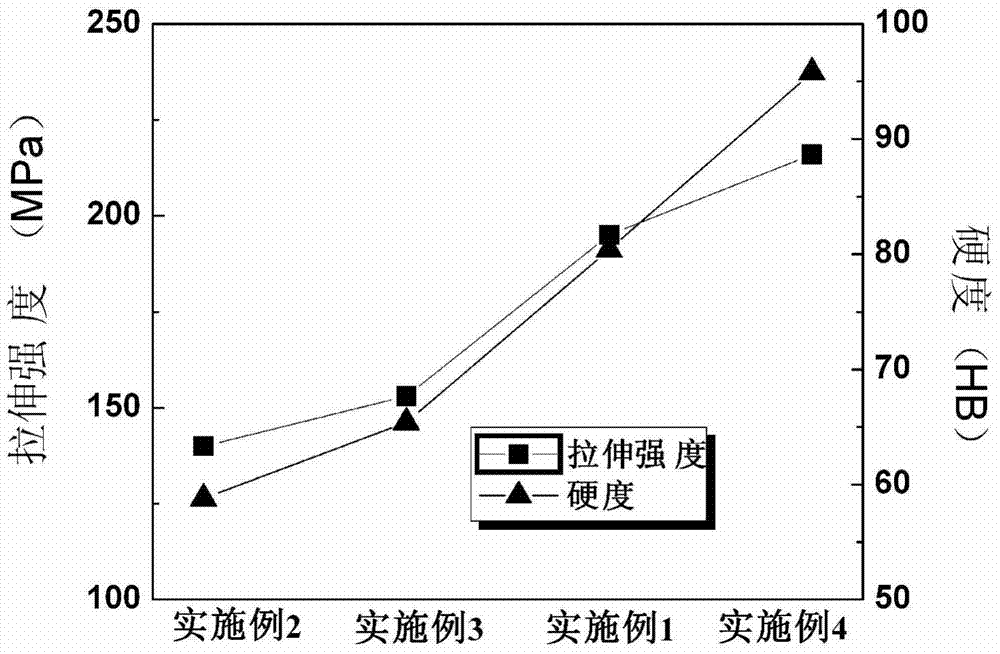

[0046] Example 2 The difference between this embodiment and Embodiment 1 is that the thickness of the aluminum foil in step 2 is 0.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com