Preparation method for siloxane-terminated organosilicon block polyurethane prepolymer

A polyurethane prepolymer, polyurethane prepolymerization technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., to achieve the effects of easy marketization, good elasticity, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

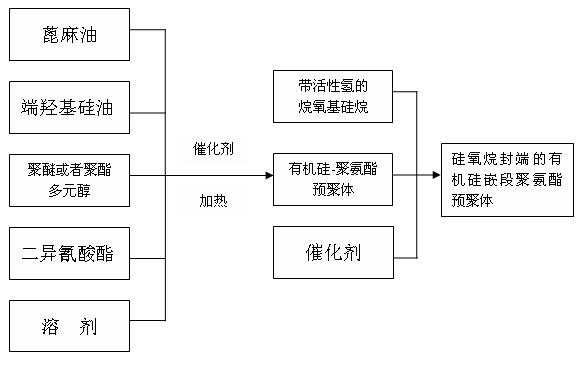

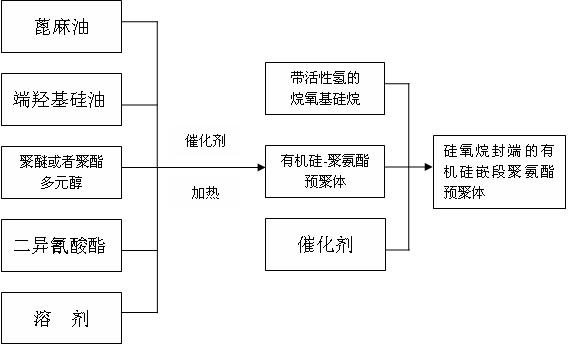

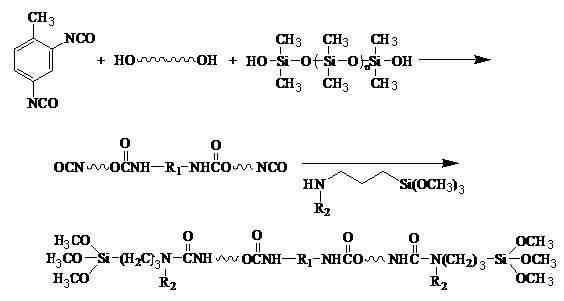

Method used

Image

Examples

Embodiment 1

[0034] Add 200.0g of hydroxyl-terminated polyethylene oxide with an average molecular weight of 4500~6000 into a four-neck flask equipped with a thermometer, condenser, stirring device and vent tube, and raise the temperature to 80°C in a water bath within 30 minutes, and the vacuum degree is 0.09MPa Stir under the conditions, vacuum degassing for 1 hour, cool down to 50°C, stop stirring and vacuumize; then add 40.0g hydroxyl-terminated silicone oil, 30.0g toluene diisocyanate (TDI), 12.0g castor oil and 100.0g cyclohexanone, Under the protection of pure nitrogen, slowly heat the above-mentioned materials to 60°C, and when the polyether is completely melted and becomes liquid, add 0.5 g of stannous octoate as a catalyst, and reflux at 90°C for 4 hours to obtain a silicone with an NCO terminal group -Polyurethane polymer, then add 16.0g 3-aminopropyltrimethoxysilane and 0.1g catalyst stannous octoate, continue to stir and react for 1h; detect-When the NCO group content value is ...

Embodiment 2

[0036] Add 260.0g of hydroxyl-terminated polypropylene oxide with an average molecular weight of 5000~6000 into a four-necked flask equipped with a thermometer, condenser, stirring device and vent pipe, and raise the temperature to 80°C in a water bath within 30min, with a vacuum of 0.09MPa Under stirring, vacuum degassing for 1h, cooling down to 50°C, stopping stirring and vacuuming; then adding 50.0g hydroxyl-terminated silicone oil, 60.0g diphenylmethane 4,4'-diisocyanate (MDI), 10.6g castor oil and 80.0 g N-methylpyrrolidone, under the protection of high-purity nitrogen, slowly heat the above-mentioned materials to 70°C, and when the polyester is completely melted and becomes liquid, add 4.0g of dibutyltin dilaurate as a catalyst, and reflux at 90°C 5h, the obtained silicone-polyurethane polymer with NCO terminal group; then add 25.0g 3-(2-aminoethyl)aminopropyl trimethoxysilane and catalyst 1.0g dibutyltin dilaurate, continue to stir the reaction 1.5h; detection - when th...

Embodiment 3

[0038] Add 260.0g of phthalic anhydride polyester polyol with an average molecular weight of 4500~6000 into a four-necked flask equipped with a thermometer, condenser, stirring device and vent pipe, and heat up to 80°C in a water bath within 30min, under the condition of a vacuum of 0.09MPa Stirring, vacuum degassing for 1h, cooling down to 50°C, stopping stirring and vacuuming; then adding 46.6g hydroxyl-terminated silicone oil, 50.0g xylylene diisocyanate (XDI), 8.8g castor oil and 68g cyclohexanone, in Under the protection of high-purity nitrogen, slowly heat the above-mentioned materials to 80°C, and when the polyester and polyether are all melted and become liquid, then add 3.0g of stannous octoate as a catalyst, and reflux at 90°C for 6 hours to obtain the terminal group: Organosilicon-polyurethane polymer of NCO, then add 30.0g 3-phenylpropyltrimethoxysilane and catalyst 2.0g dibutyltin dilaurate, continue to stir and react for 1.2h; when the detection-NCO group content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com