Nanocarbon reinforced copper-based composite material for maglev trains, and preparation method thereof

A technology of copper-based composite material and nano-carbon, applied in the field of nano-carbon reinforced copper-based composite material and its preparation, and copper-based composite material, achieving good comprehensive performance, simple and easy preparation method, and good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] modified carbon nanotubes

[0069] Add carbon nanotubes to 10 μg / mL gallic acid aqueous solution, and ultrasonically disperse for 30 minutes, wherein the ratio of the weight of carbon nanotubes to the volume of gallic acid aqueous solution is 0.1g:40mL; filter after standing for 24 hours, remove the filter residue at 60 ℃ and vacuum-dried for 2 h to obtain surface-modified carbon nanotubes.

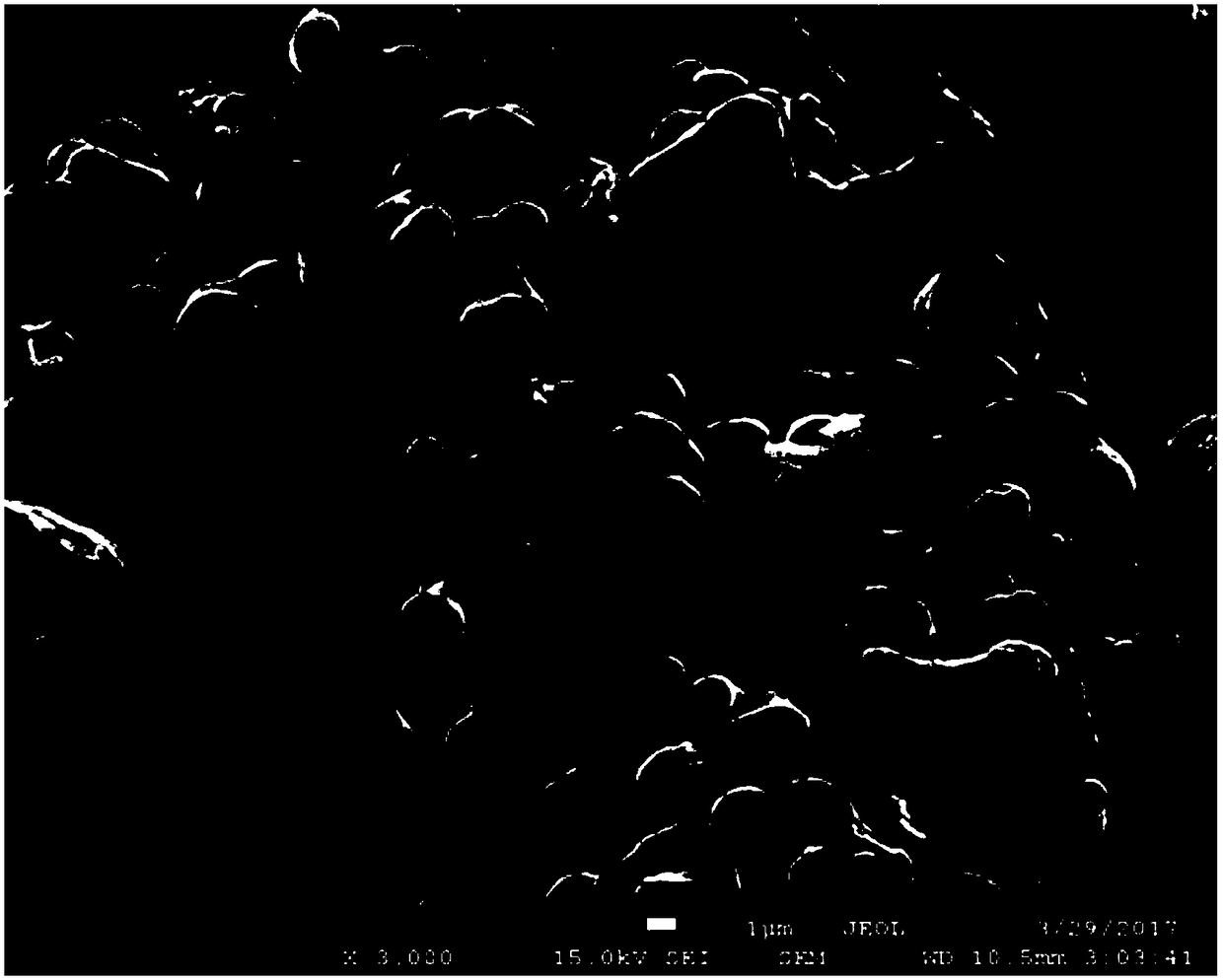

[0070] By comparing the morphology characteristics of surface-modified carbon nanotubes and non-surface-modified carbon nanotubes, it was found that the non-surface-modified carbon nanotubes were in the form of clusters or bundles, and the dispersion was poor; The surface of the carbon nanotubes is smooth, and many individual carbon nanotubes can be observed, and the aspect ratio does not change much.

[0071] Evenly disperse 0.1 g of the surface-treated carbon nanotubes prepared in this Example 1 in 100 mL of deionized water, and after standing for 5 days, the precipitation gra...

Embodiment 2

[0073] modified carbon nanotubes

[0074] According to the method of Example 1, the concentration of the gallic acid aqueous solution was changed to 5 μg / mL and 15 μg / mL, and the rest were the same as in Example 1 to obtain surface-modified carbon nanotubes respectively.

[0075] Evenly disperse 0.1 g of the carbon nanotubes prepared in Example 2 that have been surface-treated with gallic acid aqueous solutions with a concentration of 5 μg / mL and 15 μg / mL in 100 mL of deionized water, and after standing for 2 to 3 days, under the action of gravity Precipitation gradually increased, but the carbon nanotubes remained dispersed.

[0076] Combining the results of Example 1 and Example 2, the carbon nanotubes after the surface modification of the gallic acid aqueous solution have good dispersibility, and the impurity content is reduced; and when the concentration of the gallic acid aqueous solution is 10 μg / mL, the surface modification effect is the best .

Embodiment 3

[0078] modified graphene

[0079] Add graphene into 0.02μg / mL rutin aqueous solution, ultrasonically disperse for 30min, wherein the ratio of the weight of graphene to the volume of rutin aqueous solution is 0.1g:40mL; after standing for 24h, filter, remove the filter residue at 60℃ Dry under vacuum for 2 h to obtain surface-modified graphene.

[0080] By comparing the SEM images of surface-modified graphene and graphene without surface modification, it was found that the graphene without surface modification was in the form of clusters or bundles, and the dispersion was poor; the surface of graphene with surface modification Bright and clean, many individual graphenes can be observed with little change in size.

[0081] The surface-treated graphene 0.1g prepared in the present embodiment 3 is evenly dispersed in 100mL deionized water, and after standing for 5 days, the precipitation gradually increases under the action of gravity, but the graphene still maintains a dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com