Dead-time optimization control method suitable for SiC-based bridge arm power circuit

A dead-time and optimized control technology, applied in output power conversion devices, electrical components, high-efficiency power electronic conversion, etc. It can reduce the loss, improve the work efficiency of the whole machine, and improve the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

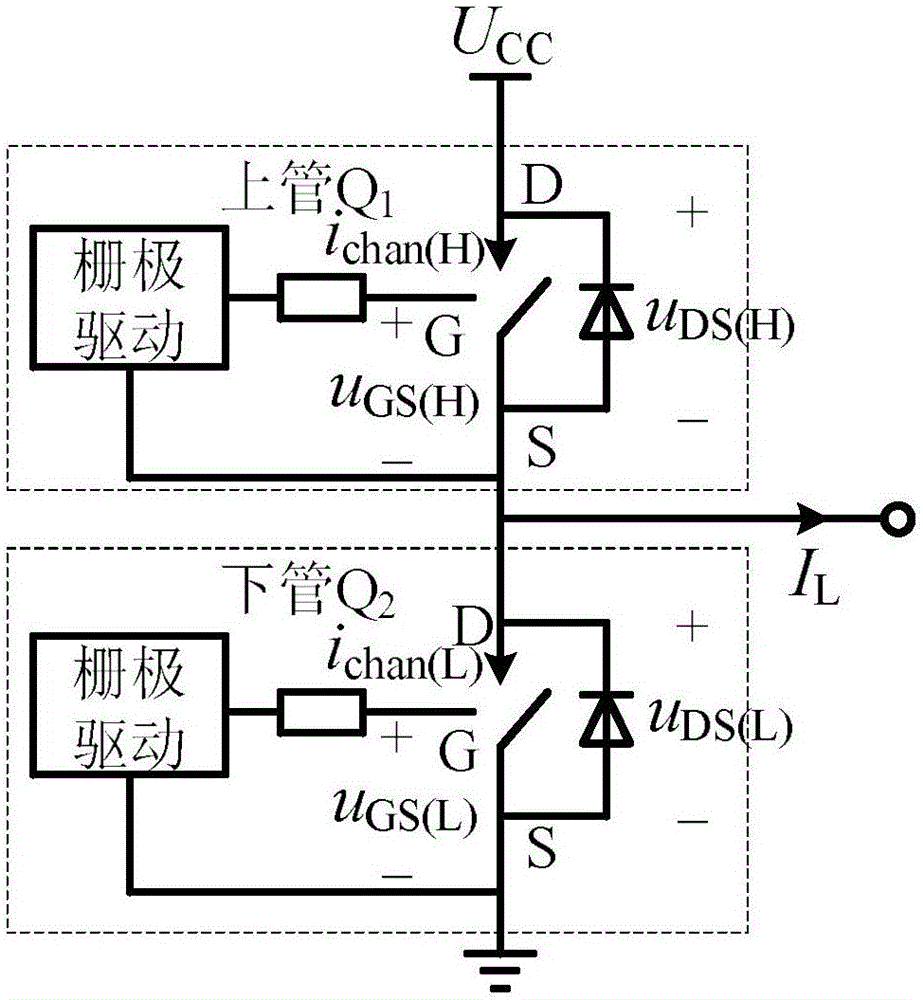

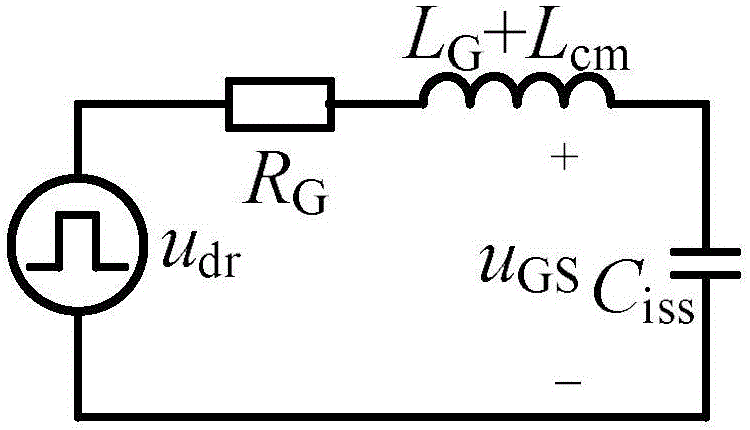

[0028] The embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the accompanying drawings. The following embodiments described with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

[0029] The present invention proposes a dead time optimization control method suitable for SiC-based bridge arm power circuits. By real-time detection of the working state of the switch tube, the dead time of the control signal can be adjusted according to the load condition, thereby ensuring the reliability of system operation On this basis, it effectively reduces the loss caused by the redundant dead time and improves the working efficiency of the converter.

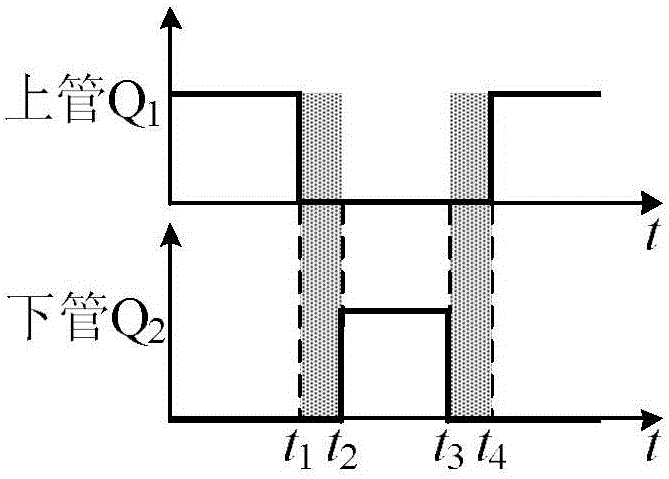

[0030] by figure 2 As shown, in the control signal of the bridge arm circuit, two dead time needs to be set in one switching cycle, respectively: (1) The dead time befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com