Fabricated shear wall structure in combination of steel plates and section steel

A prefabricated shear wall technology, applied in the direction of walls, building components, building types, etc., can solve the problems of large welding volume, difficult construction, and complex component manufacturing, and achieve convenient and fast construction, high seismic performance, and simple component manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

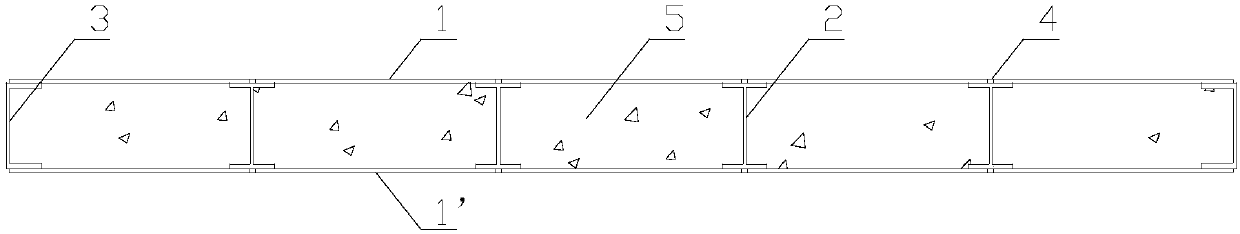

[0029] The prefabricated shear wall structure of the present invention, such as Picture 1-1 , Figure 1-2 , 1-3 As shown, several long holes 4 are respectively arranged on two oppositely arranged steel plates 1, 1'; several pieces of I-shaped steel 2 are arranged between the two steel plates 1, 1'; and through the long holes The steel plates 1, 1' and the I-shaped steel 2 are respectively welded and fixed at 4 places; the two ends of the steel plates 1, 1' on both sides are respectively welded with edge channel steel 3 to form several internal cavities 5; Concrete is poured into the cavity 5 to finally form a prefabricated shear wall structure.

Embodiment 2

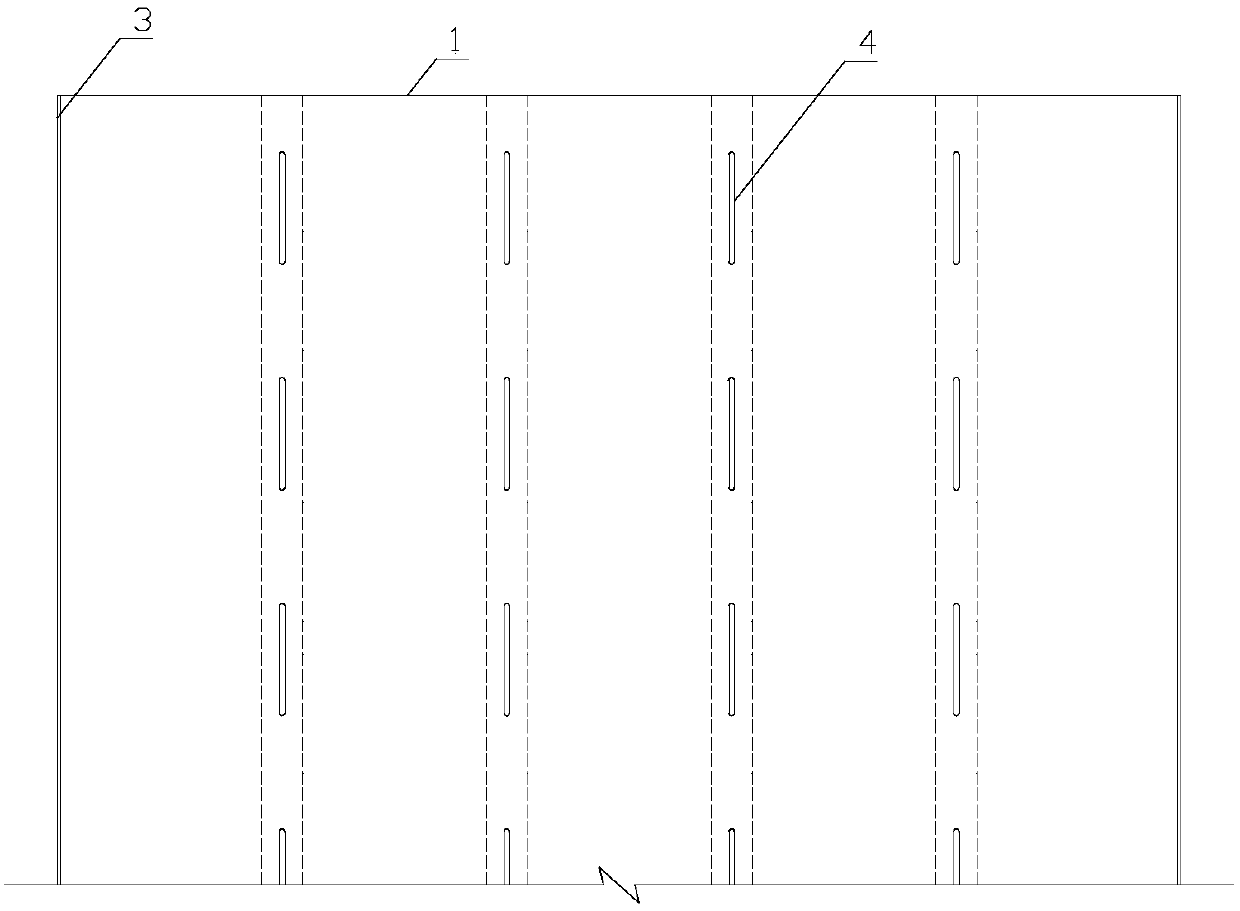

[0031] The prefabricated shear wall structure of the present invention, such as figure 2 As shown, several long holes 4 are respectively arranged on two oppositely arranged steel plates 1, 1'; several channel steels 21 are arranged between the steel plates 1, 1' on both sides; and through the long holes 4 The steel plates 1, 1' and the I-shaped steel 2 are respectively welded and fixed; the two ends of the steel plates 1, 1' on both sides are respectively welded with edge channel steel 3 to form several internal cavities 5; Concrete is poured into the cavity 5 to finally form a prefabricated shear wall structure.

Embodiment 3

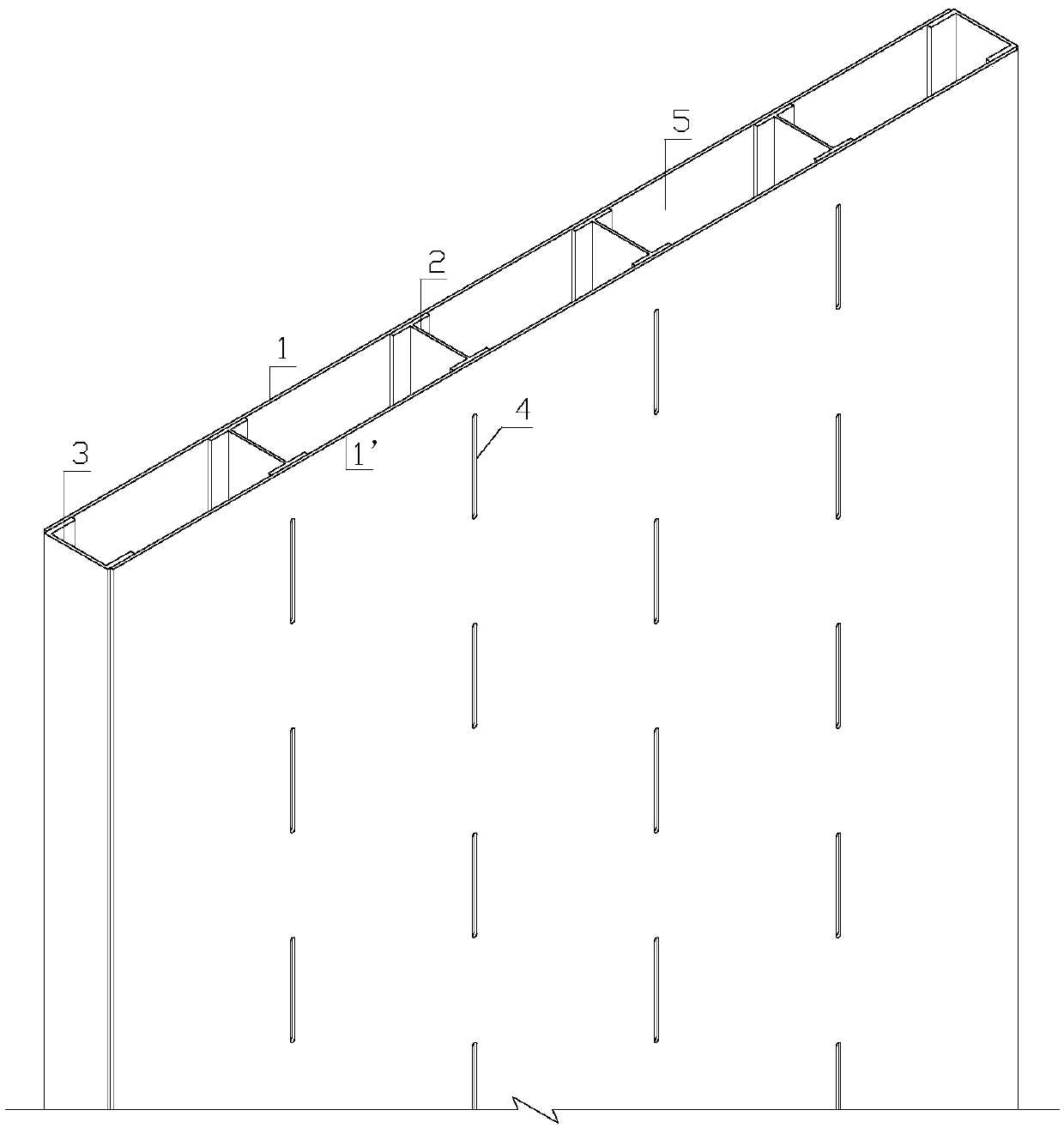

[0033] The prefabricated shear wall structure of the present invention, such as image 3 As shown, several long holes 4 are respectively arranged on two oppositely arranged steel plates 1, 1'; several pieces of C-shaped steel 22 are arranged between the steel plates 1, 1' on both sides; and through the long holes 4 The steel plates 1, 1' and C-shaped steel 22 are welded and fixed respectively; edge C-shaped steels 31 are respectively welded at both ends of the steel plates 1, 1' on both sides to form several internal cavities 5; Concrete is poured into the cavity 5 to finally form a prefabricated shear wall structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com