Distributor applied to falling film type evaporator

A technology of falling film evaporator and distributor, which is applied in evaporator/condenser, fluid circulation arrangement, refrigeration components, etc. It can solve problems such as failure to meet requirements and unsatisfactory distribution uniformity, and achieve high reliability of liquid separation , Simple and compact structure, small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

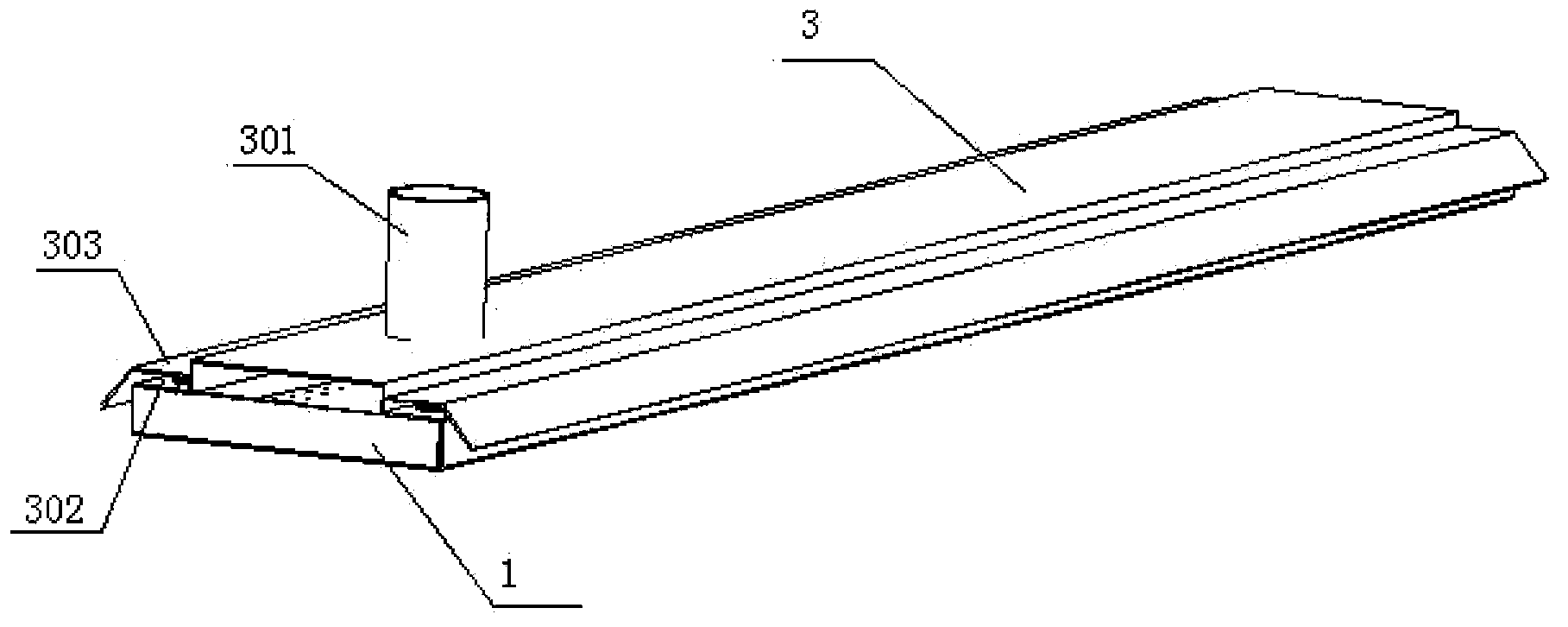

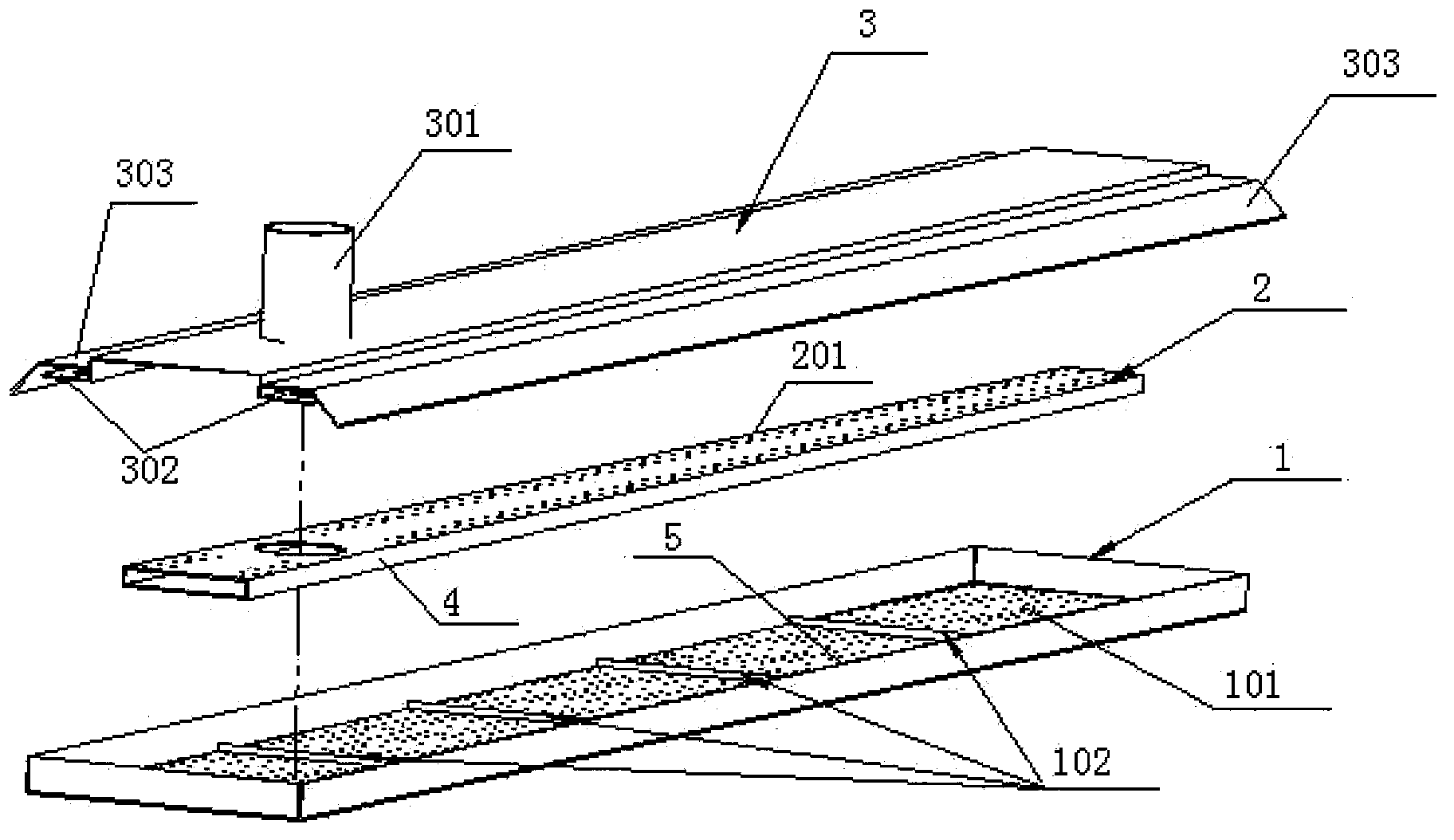

[0011] like figure 1 , figure 2 As shown, a distributor used in a falling film evaporator, it includes a rectangular gravity box 1 with an open top, the bottom of the gravity box 1 is uniformly covered with circular first through holes 101, the gravity The bottom of the box 1 is evenly provided with four parallel slender partitions 102 along the width direction. The partitions 102 are provided with a rectangular and hollow pressure box 2. The outer side wall 4 of the pressure box 2 is connected to the gravity box. There is a gap between the 5 inner side walls of 1, that is, the pressure box 2 is installed in the gravity box 1, and the surroundings of the pressure box 2 are not in contact with the surroundings of the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com