Air guide cover, engine and power equipment

A technology for wind deflectors and engines, which is applied to the cooling of mechanical equipment, engine components, and engines. It can solve problems such as difficulty in achieving engine heat dissipation effects and ideal noise reduction effects, so as to improve heat dissipation effects, reduce airflow resistance and Effects of energy consumption and reduction of aerodynamic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

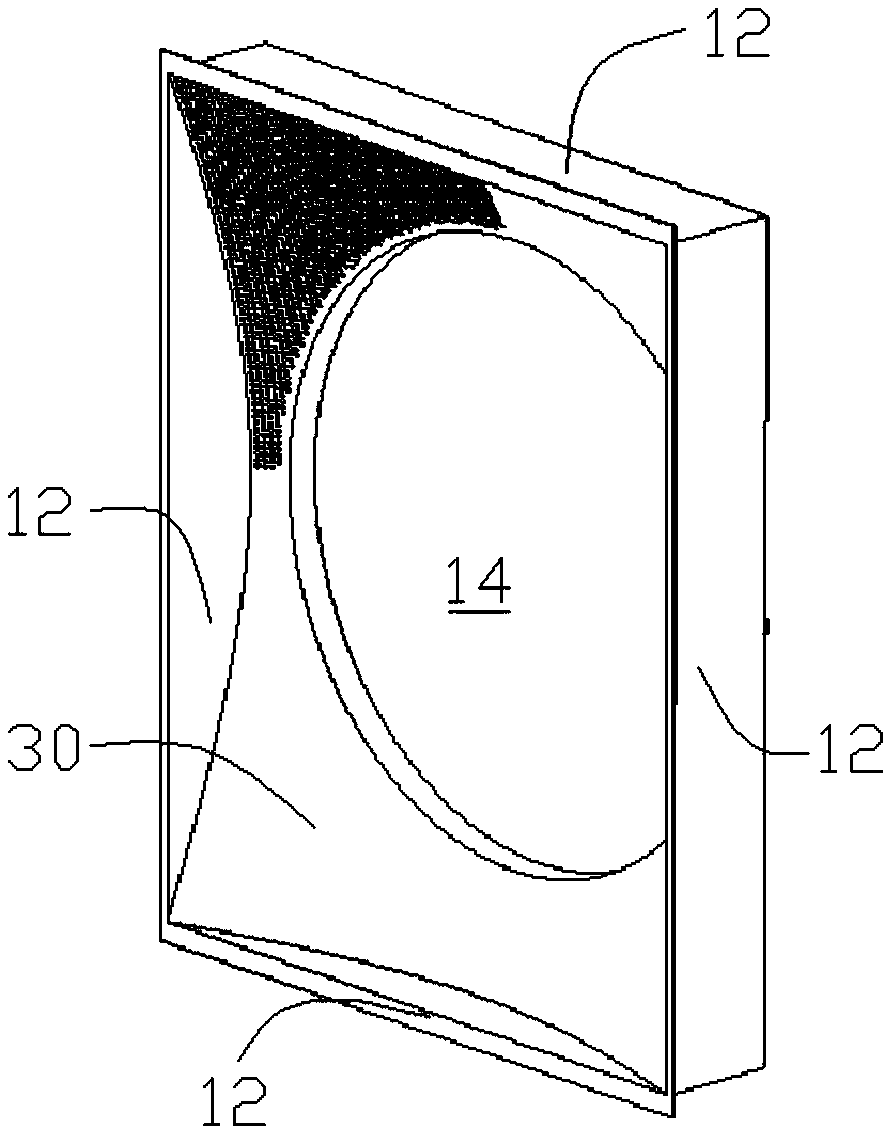

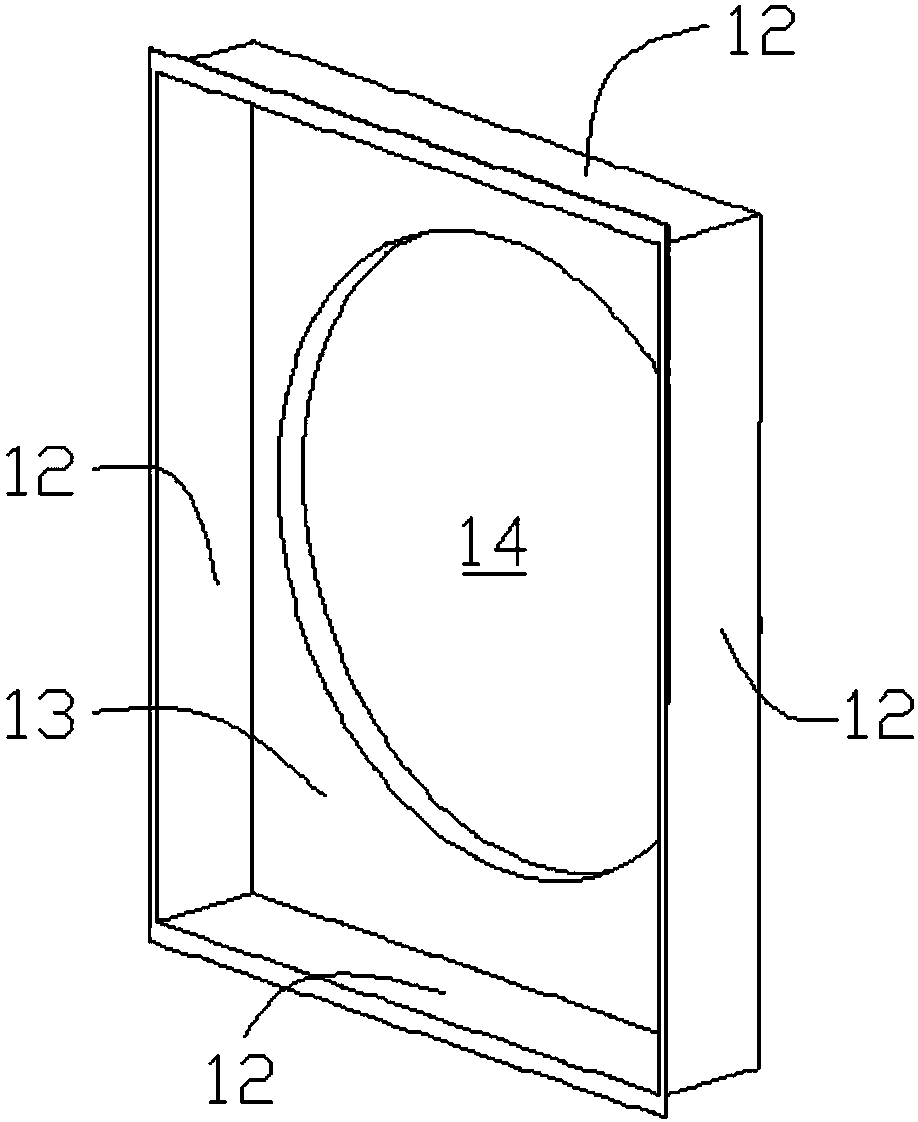

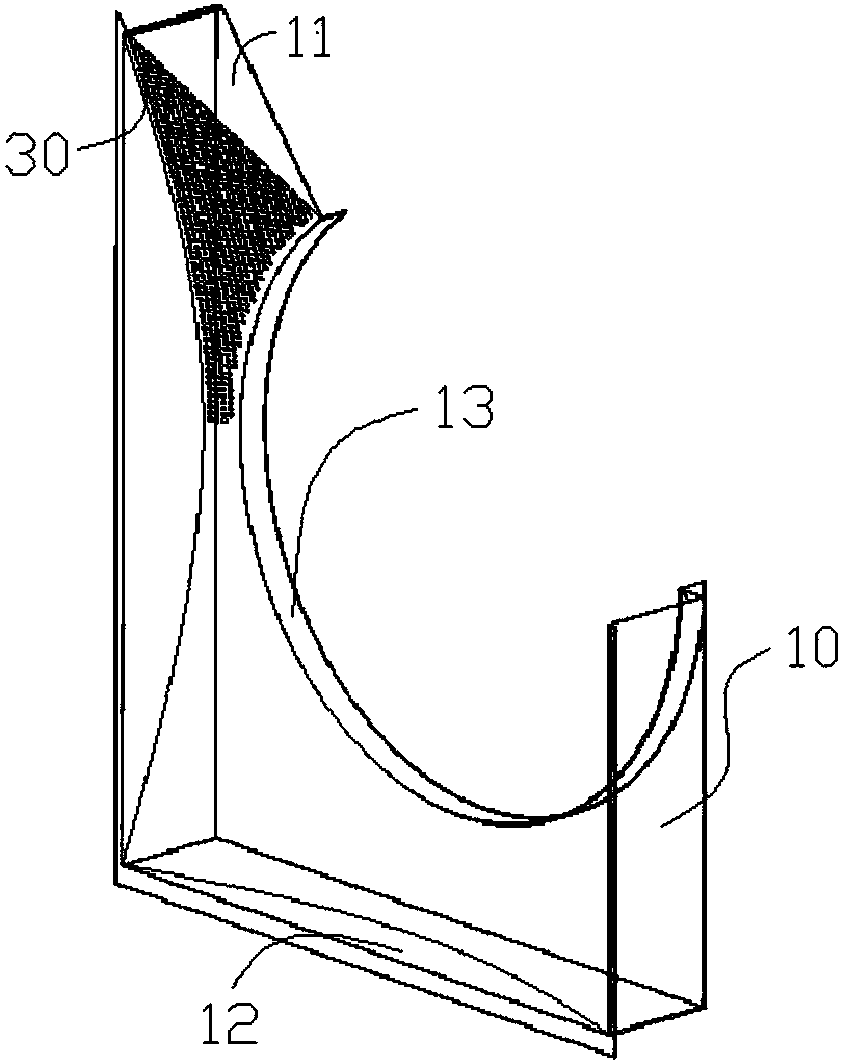

[0028] On the one hand, if Figure 1-5 As shown, the air guide hood proposed by the present invention includes a casing 10, and also includes a lining plate 30 arranged in the casing 10. The lining plate 30 and the casing 10 form a cavity 11, and the lining plate 30 is provided with perforations. , the cavity 11 communicates with the inner space of the casing 10 through the perforation, that is, a resonance cavity is formed. In the air guide hood, the noise generated when the fan 40 in the air guide hood is running is transmitted to the cavity 11 through the perforation, and the air in the perforation will generate intense vibration and friction, so that the soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com