Non-volute backward centrifugal ventilator

A centrifugal fan without volute technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc. It can solve the problems of blade inlet flow deterioration, reduce inlet air flow loss, reduce inlet vortex noise, and avoid The effect of mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

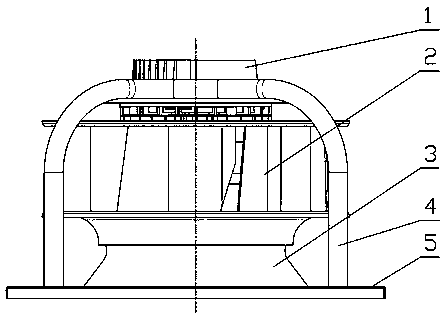

[0025] refer to figure 1 , this figure is a schematic diagram of an embodiment of a backward centrifugal fan without volute according to the present invention. The panel 5 is fixedly connected, the other end of the bracket 4 is fixedly connected with one end of the motor 1; the other end of the motor 1 is connected with one end of the impeller 2, the other end of the impeller 2 is connected with one end of the air inlet 3, and the other end of the air inlet 3 is connected with the The panel 5 is fixedly connected, the rear plate of the impeller is fixedly connected with the other end of the motor, and the front plate of the impeller cooperates with the sleeve of the air inlet;

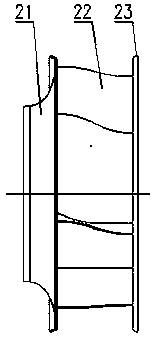

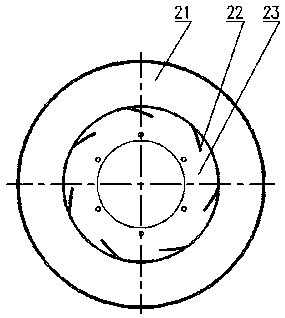

[0026] The mating section between the front disc 21 of the impeller and the air inlet 3 is an arc segment "kmn", the convex point "m" of the arc segment faces the outer diameter side, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com