Axle-flow fan blade

A technology of axial flow blades and blades, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc. It can reduce the noise of eddy current, improve the shedding of vortex and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following describes the axial fan blade of the present invention in further detail with reference to the accompanying drawings and embodiments.

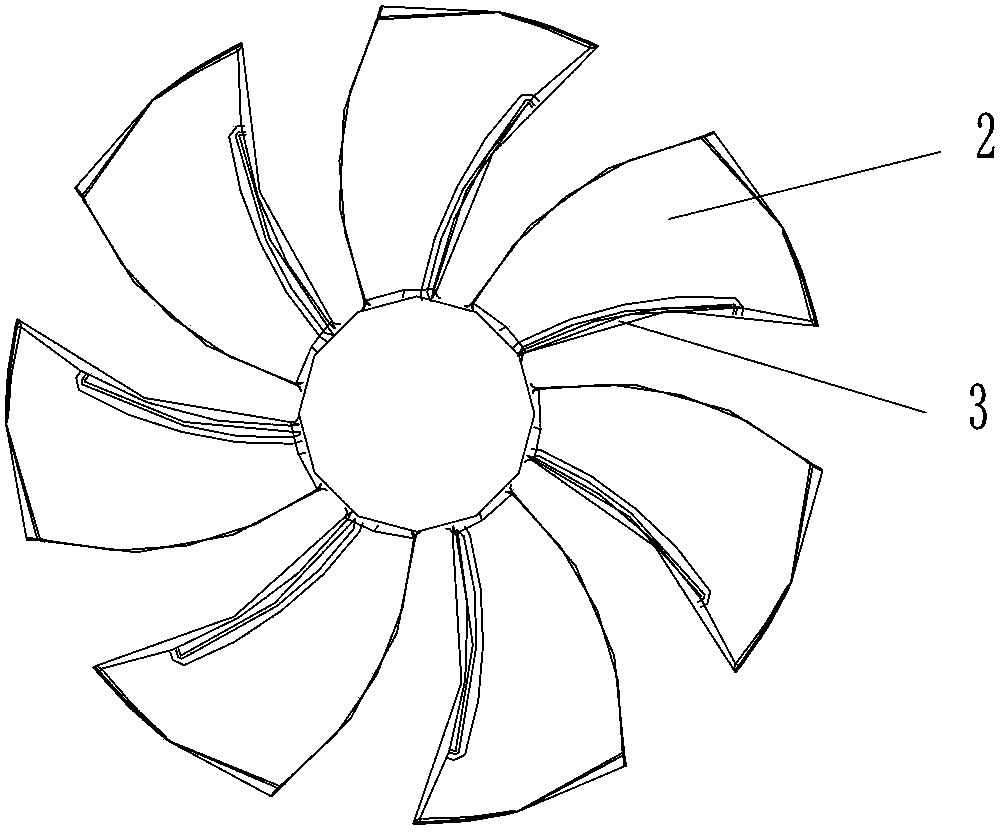

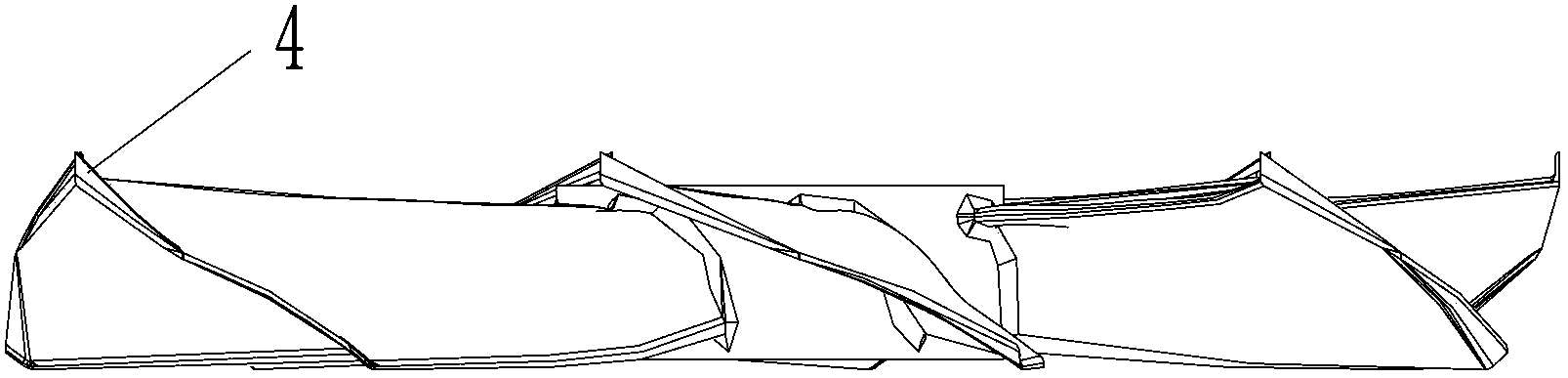

[0036] First, the blade of the axial flow blade is described. The edge of the blade facing the direction of rotation is the leading edge, the edge that faces away from the direction of rotation is the trailing edge, the radially outward edge of the blade is the outer edge, and both sides of the blade They are the pressure surface on the air outlet side and the suction surface on the air inlet side.

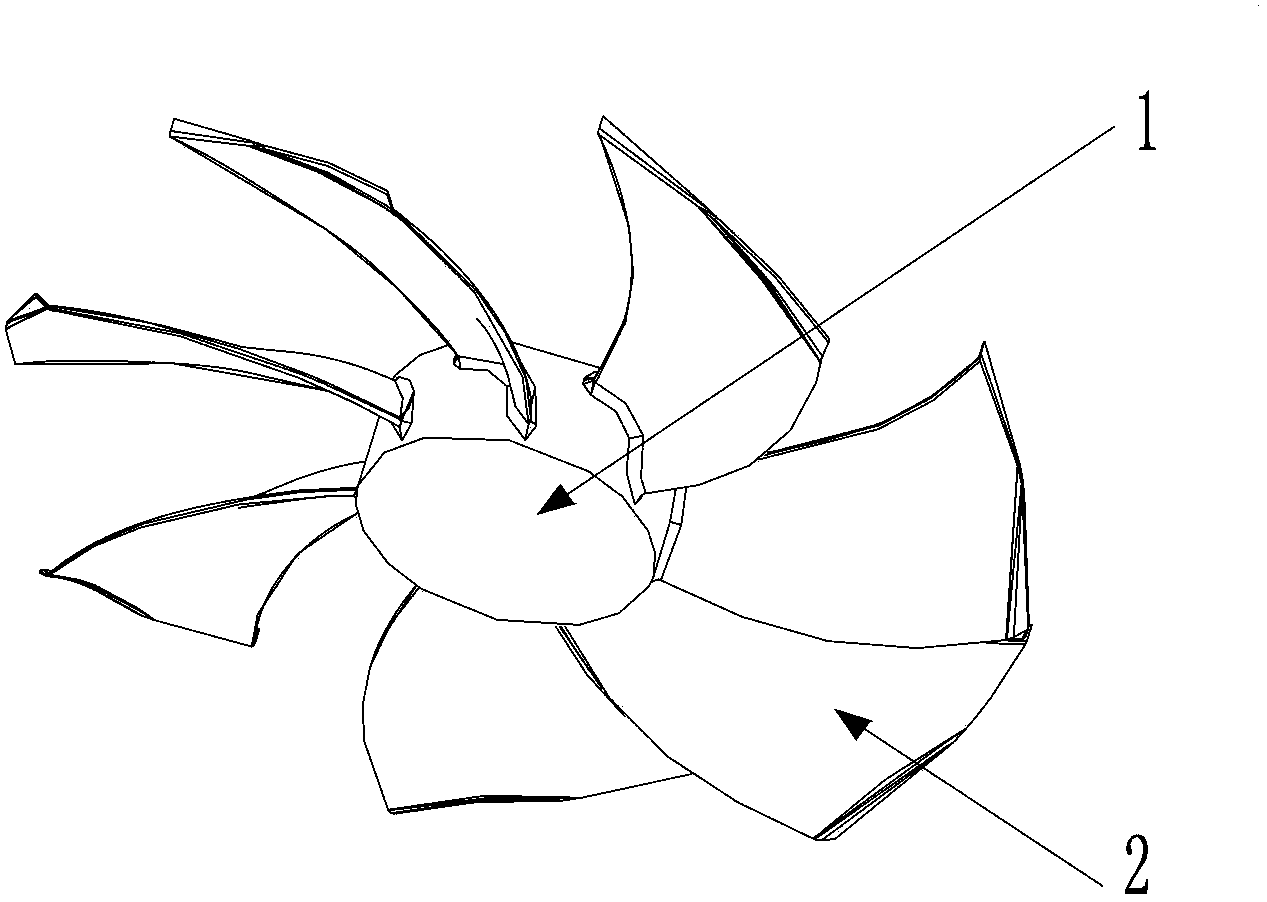

[0037] Reference Figure 1 to Figure 11 , The axial flow blade of the present invention includes a hub 1. A plurality of blades 2 are axially distributed on the hub 1. Each blade 2 has the same shape and is centered on the axis of rotation of the axial flow blade. The two sides of the blade 2 are the pressure surface T and the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com