Vane blade tip structure of vane type machine

A blade type and blade technology, applied in the field of blade tip structure of blades, can solve the problems of difficult installation of rotating shrouds, reduced applicability, etc., and achieve the effect of reducing blade tip eddy current noise of blade type machinery, remarkable results, and good manufacturability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

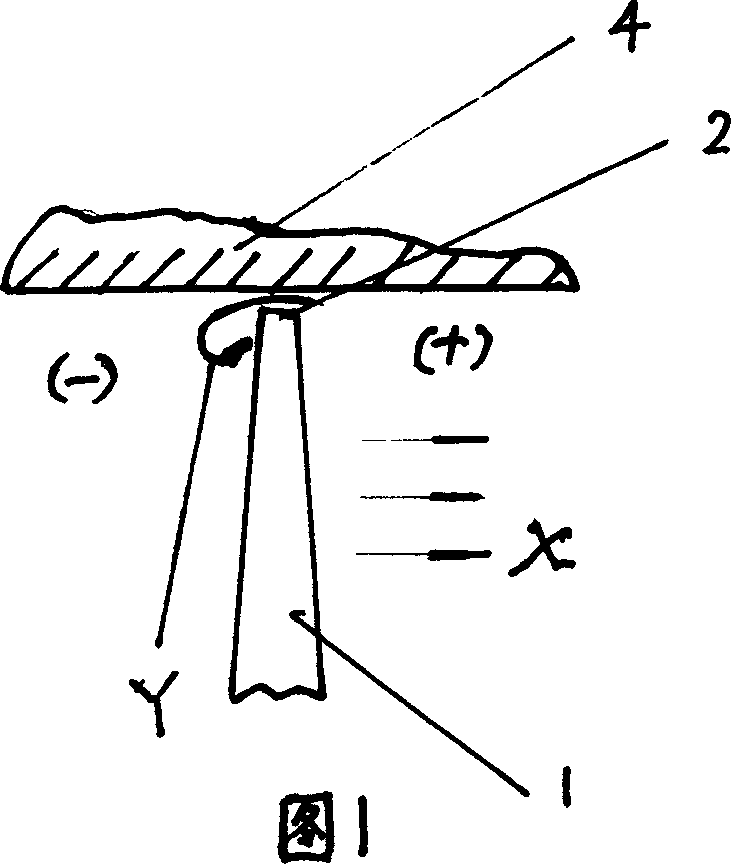

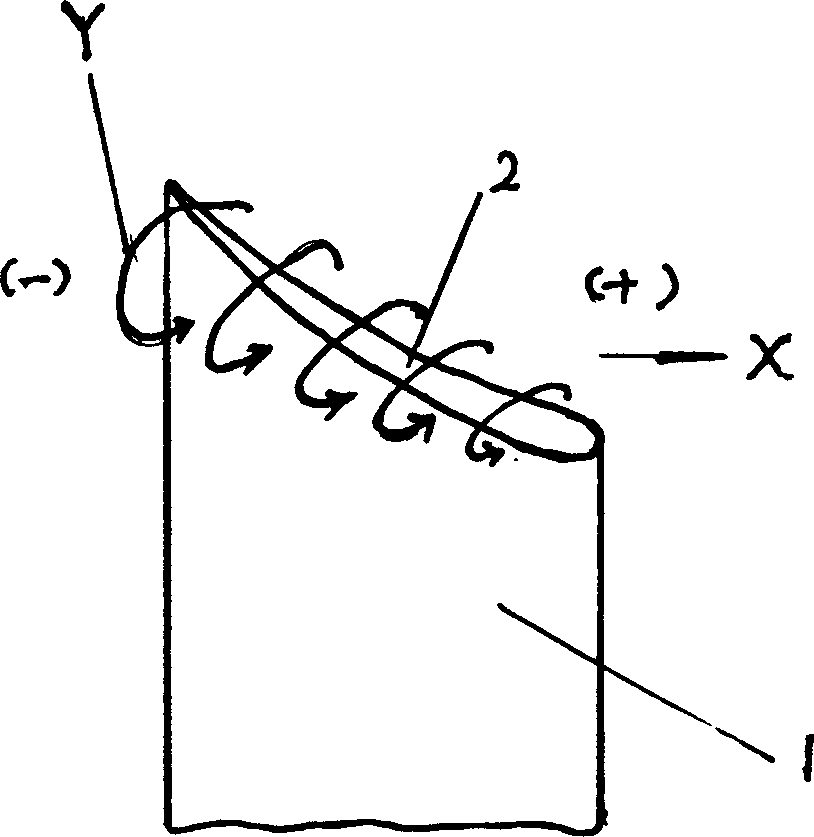

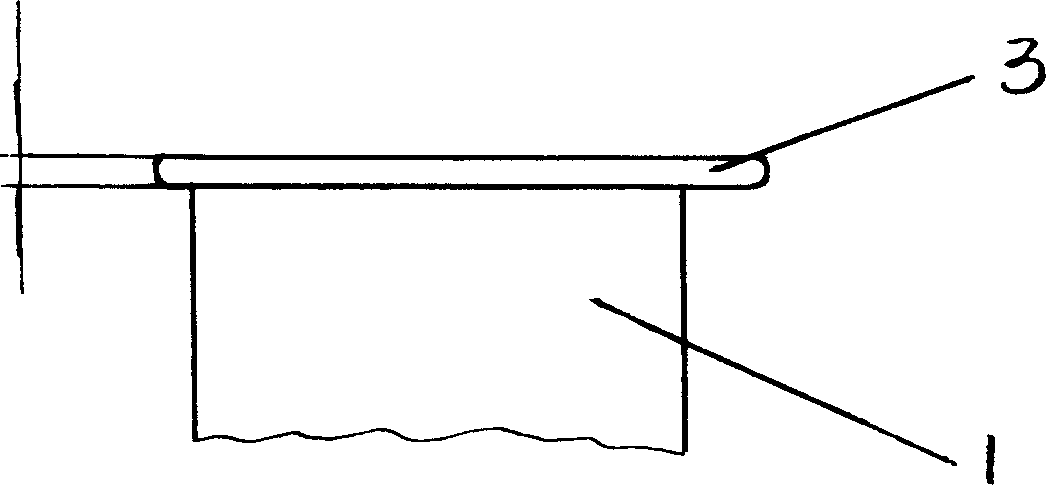

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings: an axial flow fan is taken as an example to illustrate the formation reasons and control mechanism of blade tip clearance vortex noise. In the axial flow fan, with the rotation of the fan blade 1, the load on the blade increases, forming the axial movement of the airflow, that is, the mainstream X, and also forming the pressure surface and suction surface of the blade 1 increasing from the leading edge to the trailing edge of the blade. At the same time, due to the large gap between the blade tip 2 and the fan casing 4, the air flow passes through the blade tip from the pressure surface to the suction surface, forming a blade tip vortex that is constantly expanding from the leading edge to the trailing edge of the blade. Y, as shown in Figure 1 and figure 2 shown. As the blade load increases, the pressure difference between the pressure surface and the suction surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com