Zigzag noise reduction axial flow blade

A technology of axial flow fan blades and sawtooth type, which is applied in the field of sawtooth noise reduction axial flow fan blades, can solve the problems of poor versatility of the sawtooth structure, large dynamic noise, and inconspicuous noise reduction effects, etc., and achieves improved noise reduction effects, reduced Effect of Small Eddy Noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The saw-tooth noise-reducing axial-flow fan blade of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

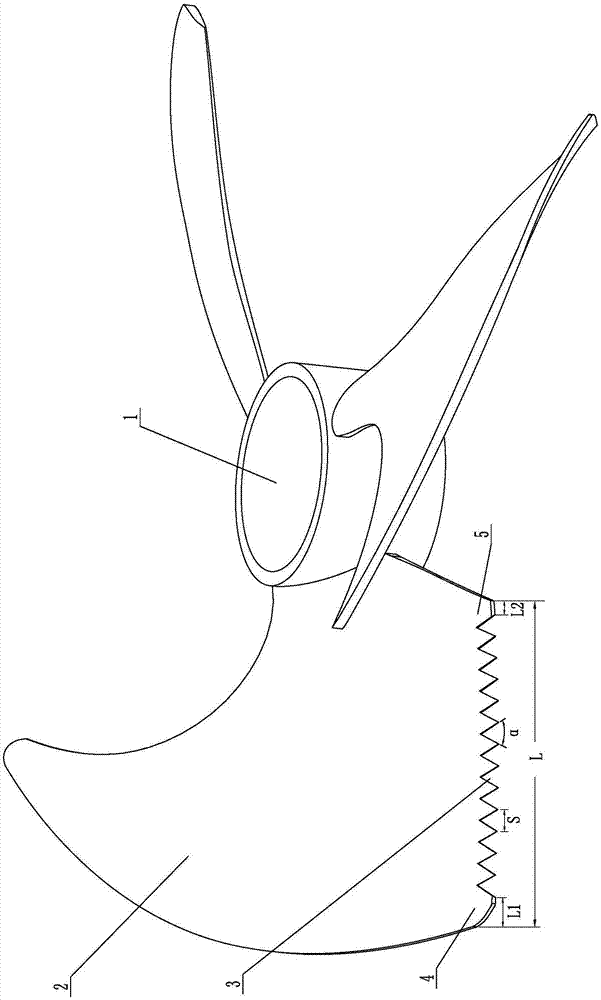

[0021] Such as figure 1 As shown, the sawtooth type noise-reducing axial fan blade of the present invention includes a hub 1 and a plurality of blades 2 uniformly distributed in the circumferential direction on the outer peripheral wall of the hub 1. A row of sawtooth grooves 3 are arranged at the trailing edge of the blades 2, and at least 1 / 4 of the sawtooth grooves 3 have the same notch width and groove depth, and all the sawtooth grooves 3 with equal notch width and groove depth are located on the outside of the blade 2, so that the collection of eddy currents at the trailing edge of the blade 2 can be further improved. Alleviate the noise, so that the noise is further improved; the distance from the bottom of the sawtooth groove 3 with the same slot width and slot depth to the trailing edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com