Wind wheel blade, cross-flow wind wheel and design method of wind wheel blade

A technology of wind turbine blades and design methods, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., and can solve the problems of low energy conversion efficiency and difficulty in ensuring fluid dynamic characteristics, etc. , to effectively control the flow separation, reduce the total value of noise, and reduce the effect of eddy current noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

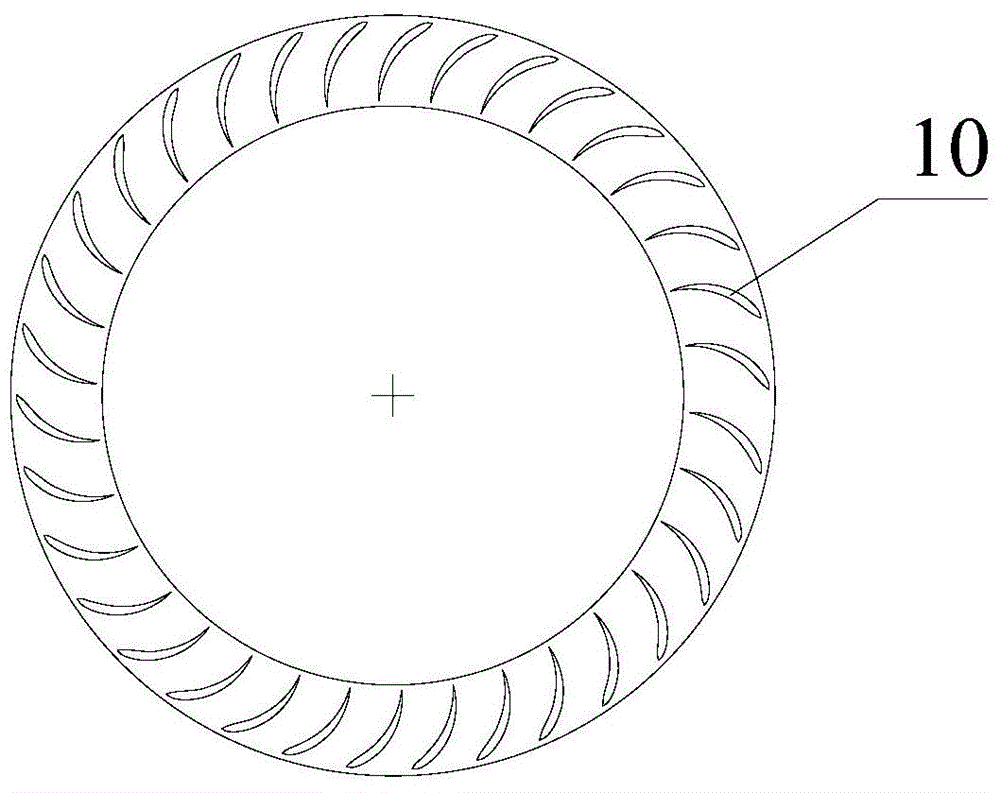

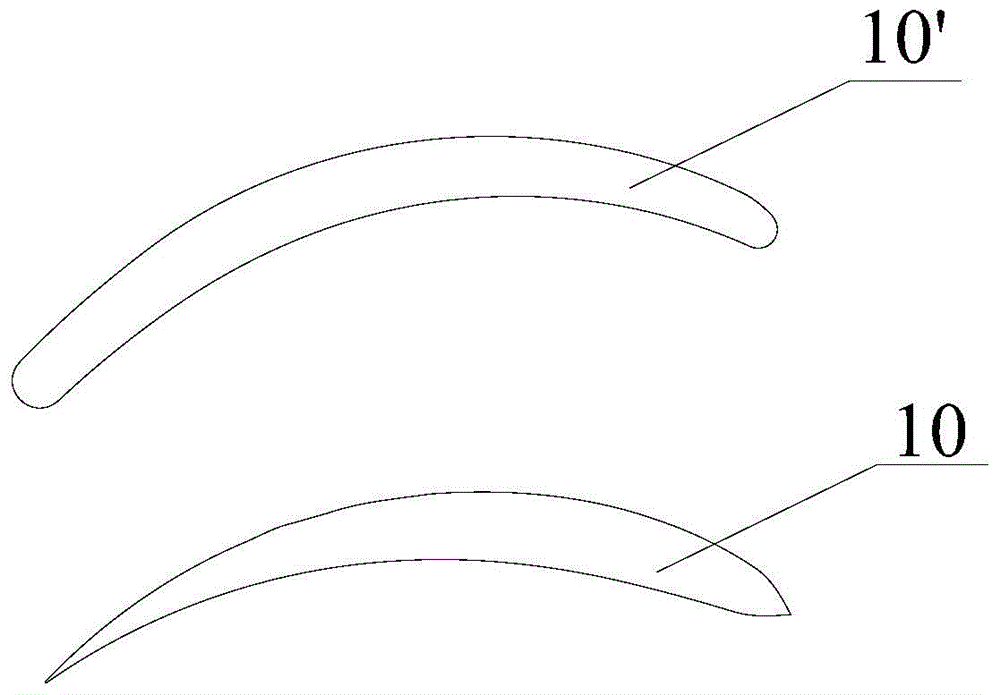

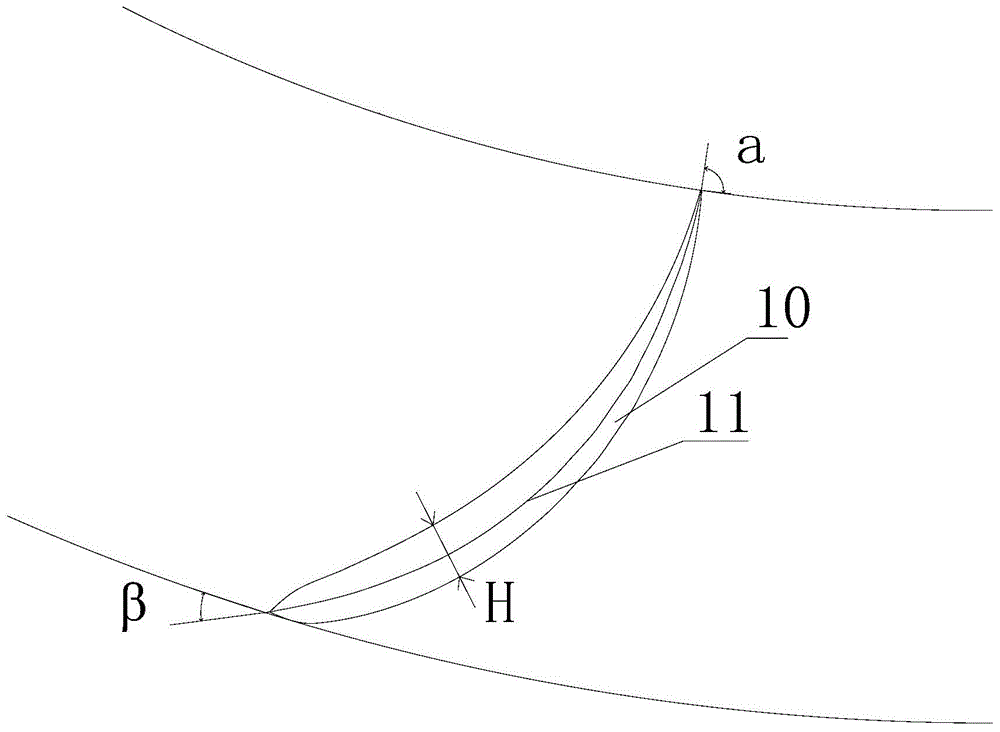

[0024] see figure 1 As shown, in the arc-shaped blade 10' in the prior art, on the section perpendicular to the rotation axis of the wind rotor (the following sections refer to the section of the blade taken perpendicular to the rotation axis of the wind rotor), the section curves of the upper and lower surfaces of the blade chord The distance between the lines is equal, the curvature of the surface curve is also unchanged, and then the two ends of the surface curve are directly connected to the arc closed (the above "upper surface" and "lower surface" are not absolute up and down directions, but as two The designation of the opposite surface can be understood as the upper surface refers to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com