Stepped volute structure, centrifugal fan and air blowing device

A volute and ladder technology is applied in the field of stepped volutes and centrifugal fans and blowing devices including the same, which can solve the problems of airflow backflow, affecting work efficiency, etc., and achieve the effect of improving noise and reducing eddy current noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

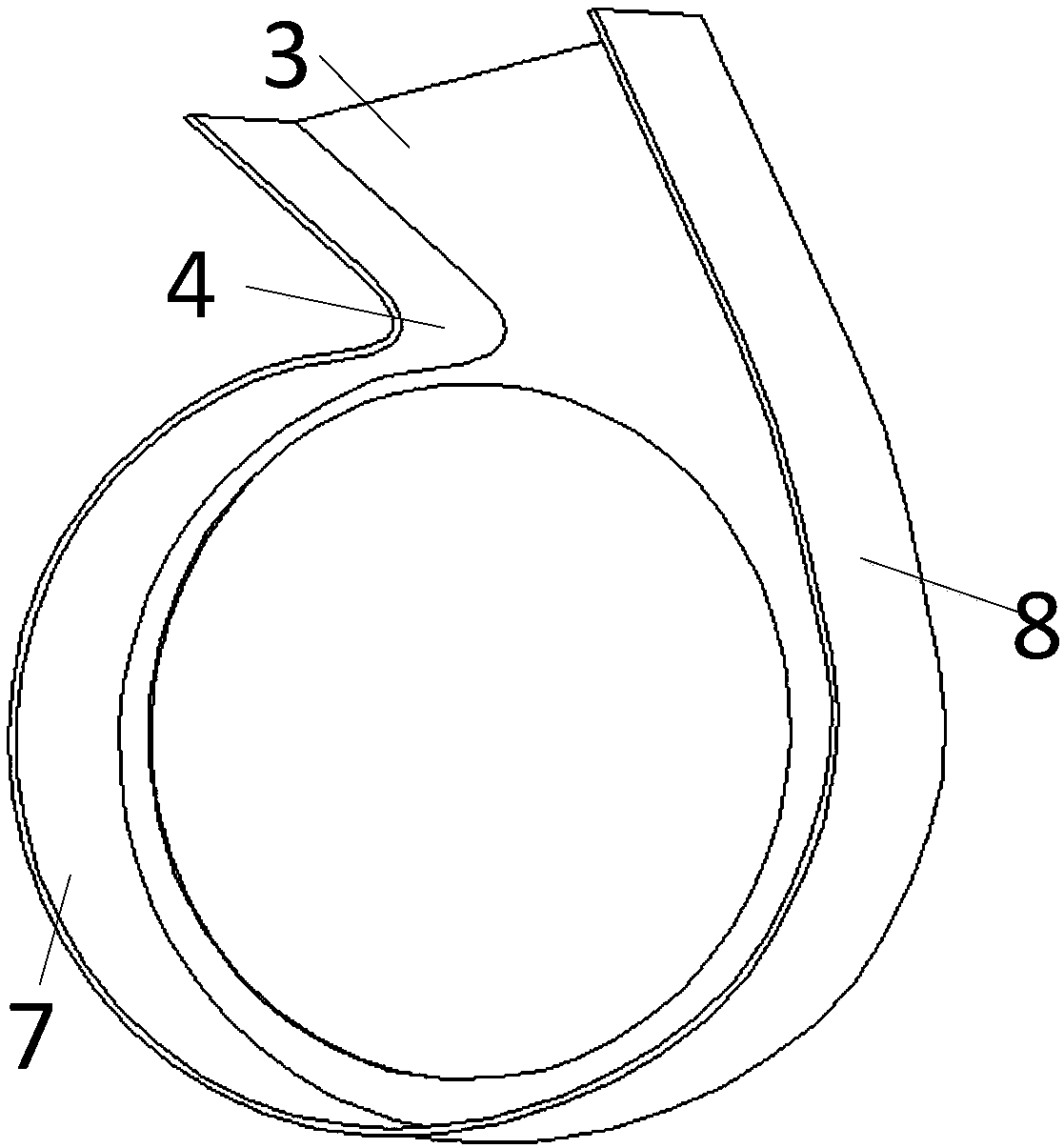

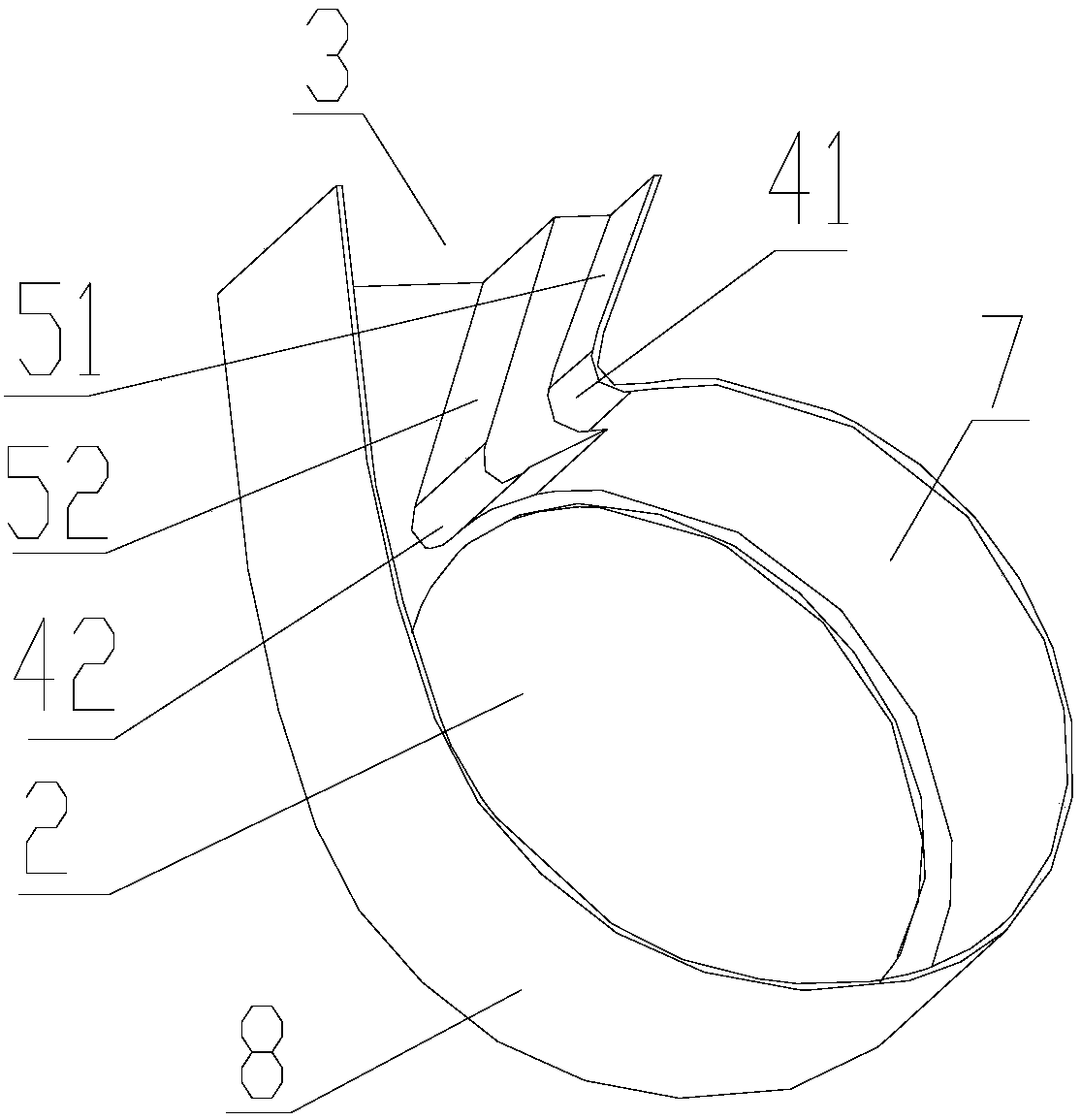

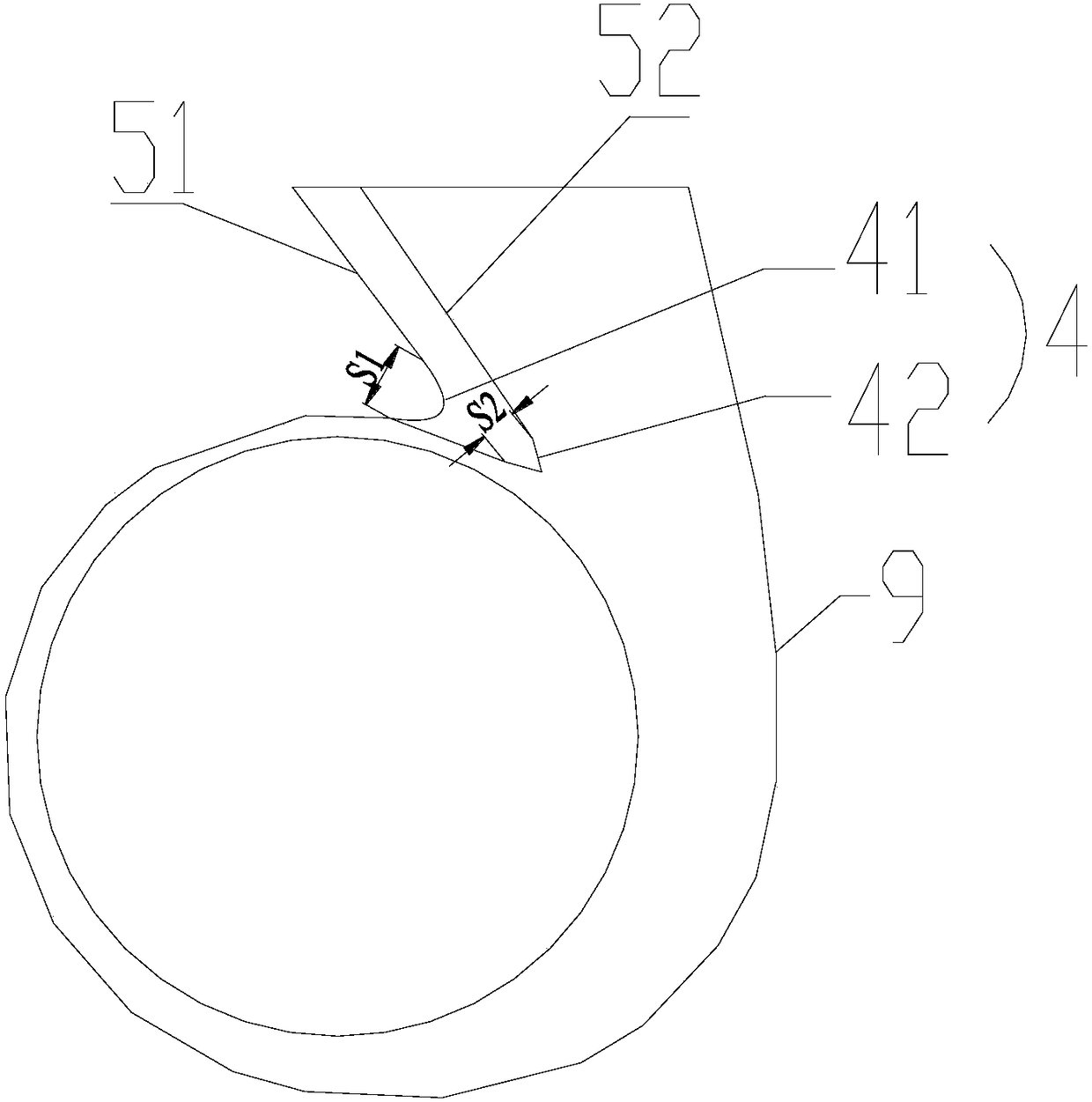

[0035] This embodiment provides a stepped volute structure, such as figure 2 As shown, it includes: a housing 1, which is provided with an air inlet 2 and an air outlet 3; a plurality of volute tongues 4 arranged side by side along the thickness direction of the volute; a volute with the same number as the volute tongue 4 The volute tongue side wall surface 5 is arranged at the position of the volute case diffuser section 6, and each of the volute case volute tongue side wall surfaces 5 is respectively connected with each corresponding volute tongue 4; several of the volute tongues 4 1. The volute tongue side wall surface 5 is arranged in a step shape, extending along the air inlet 2 to the thickness direction of the housing 1, and the volute tongue side wall surface 5 is 100mm away from the fan blade front disk 7 The distance gradually increases.

[0036] The stepped volute structure adopted in this embodiment, such as figure 2 As shown, the number of steps is 2. Specifi...

Embodiment 2

[0043] This embodiment provides a centrifugal fan, such as Figure 7 As shown, it includes the stepped volute structure described in Embodiment 1; and, the fan blade 10 is arranged at the position corresponding to the air inlet 2 inside the stepped volute structure, and the stepped volute structure is correspondingly provided with a wind blade 10 The blade front disc 7 and the fan blade rear disc 8, after the fan blades rotate, the air is driven to flow into the stepped volute structure from the air inlet 2, and then the wind is driven to flow out from the air outlet 3.

[0044] The centrifugal fan provided in this embodiment adopts a stepped volute structure, and compared with the traditional centrifugal volute structure, the air volume can be increased by 80-150m 3 / h, the noise is reduced by 0.8-1.7dB.

Embodiment 3

[0046] This embodiment provides a blower device, including at least one set of centrifugal fans provided in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com