Vertical hydraulic straightening machine

A straightening machine and hydraulic technology, applied in the field of straightening machines, can solve the problems of large frictional resistance between the worktable and the base, irregular deformation of the workpiece, unstable center of gravity, etc., to ensure the straightening quality, reduce the motor power, reduce the The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

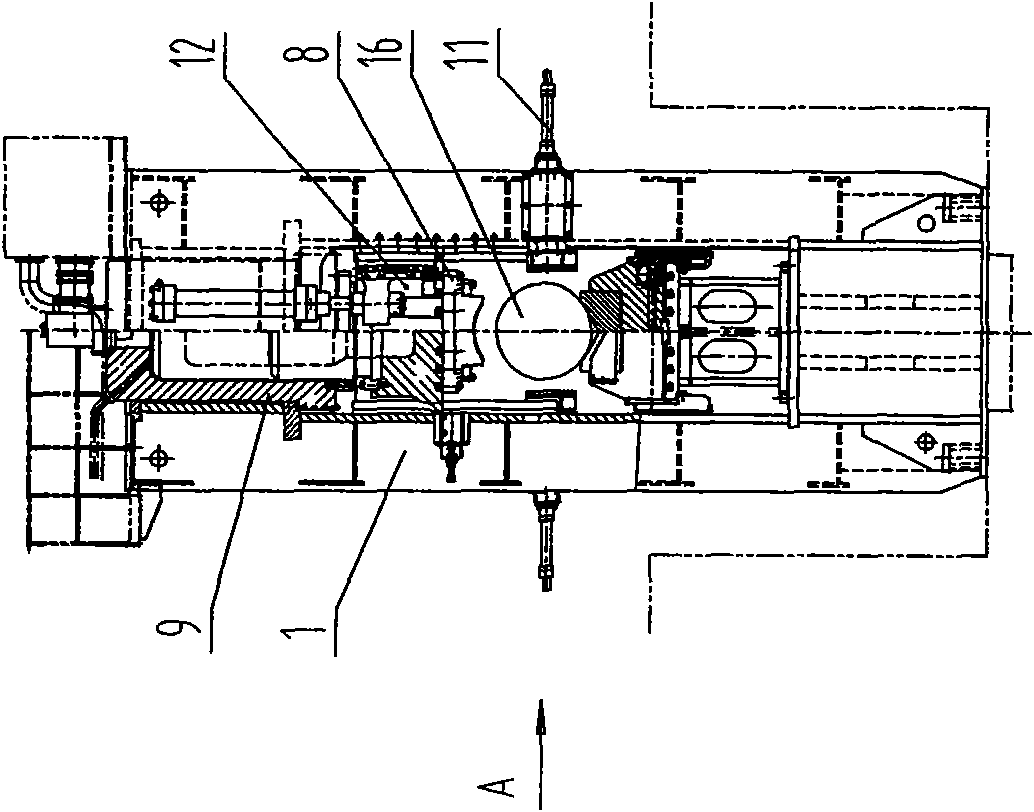

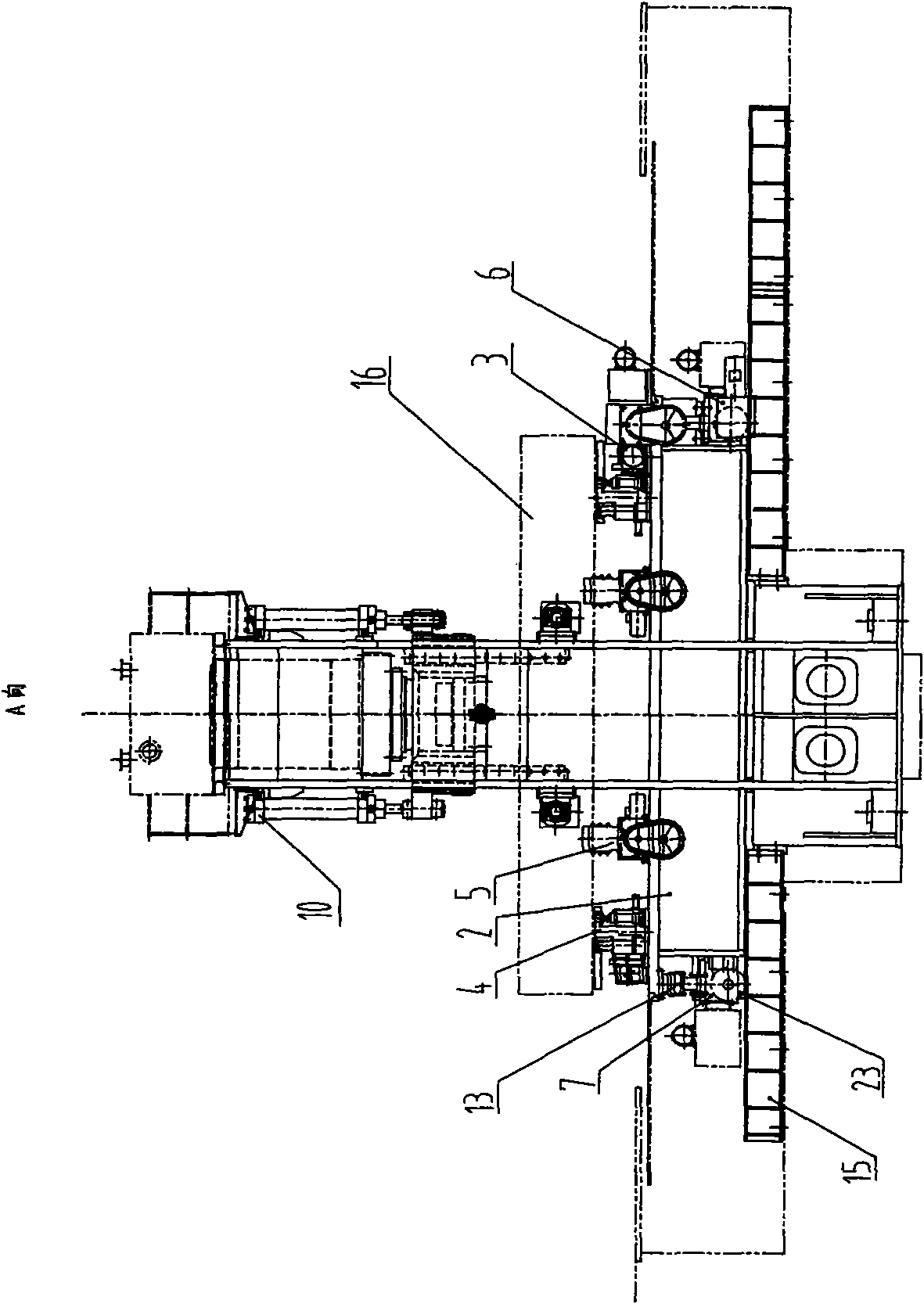

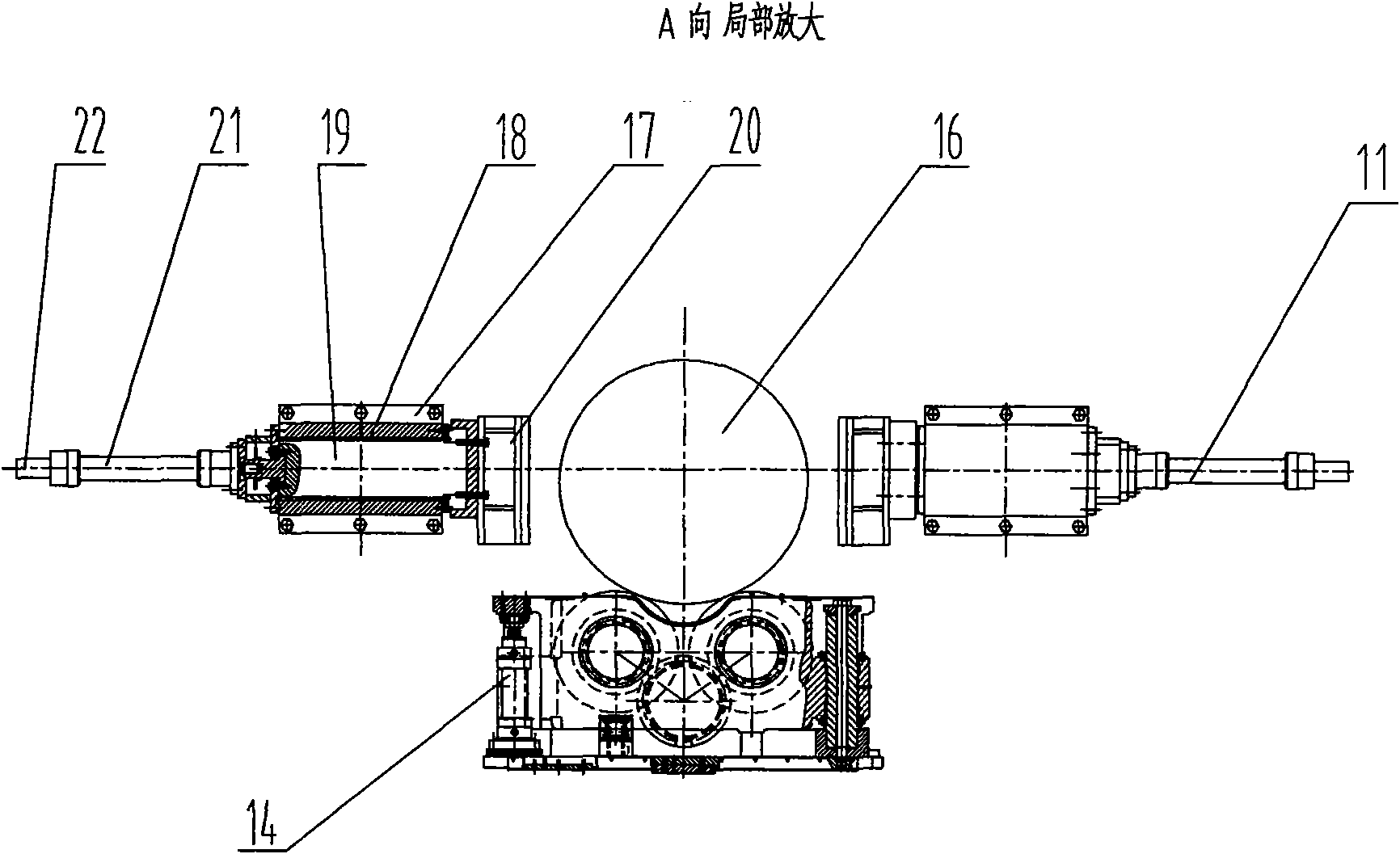

[0015] Such as figure 1 , 2 , shown in 3, a kind of vertical hydraulic straightening machine, comprises: frame 1, is installed in the workbench 2 of frame bottom, moves on base 15, is arranged on the left rotary mechanism 4 of workbench 2 upper surfaces, right Slewing mechanism 3, master cylinder 9, return cylinder 10 and movable beam 12 installed on frame 1, pressure head 8 fixed on movable beam 12, two V-shaped supports 5 arranged on the upper surface of workbench 2.

[0016] The workbench 2 is a box-shaped welded steel plate. The two ends of the workbench 2 are respectively provided with four plunger cylinders 13 and four wheels 23. The hydraulic oil enters the plunger cylinders 13 and lifts up to work. Table 2. After the pressure is released, the table 2 falls on the frame 1, and the press can be pressurized to start working.

[0017] The two ends of the workbench 2 are respectively equipped with a main transmission mechanism 6 and a driven transmission mechanism 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com