Drive system applicable to large-tonnage servo direct-driven hot die forging press

A technology of hot die forging press and transmission system, applied in the field of transmission system, can solve the problems such as dare not choose high-power servo motor, cannot meet the requirements of direct drive, and the servo motor is expensive, and achieves the goal of overcoming the lack of force enhancement effect. Ideal, reduced power, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

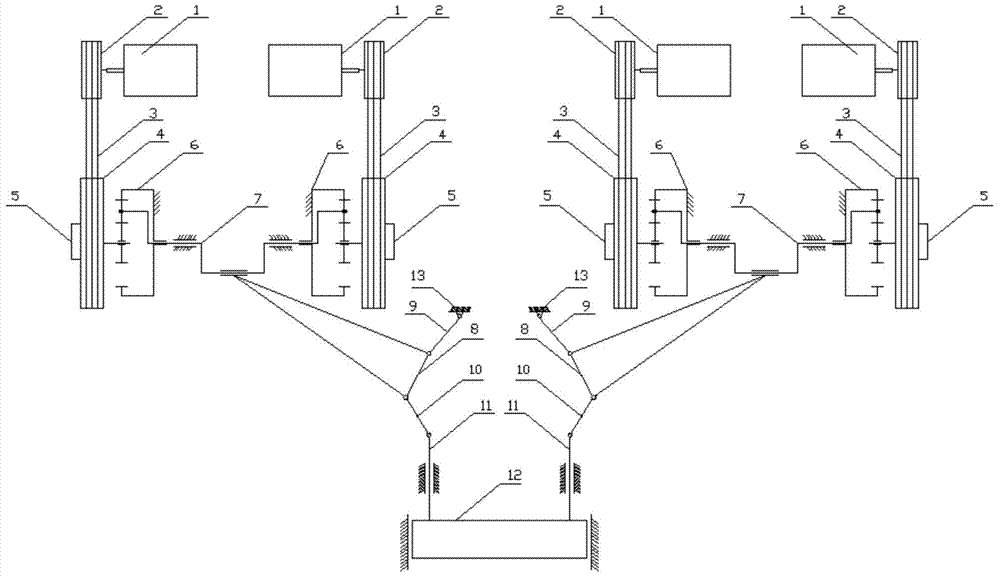

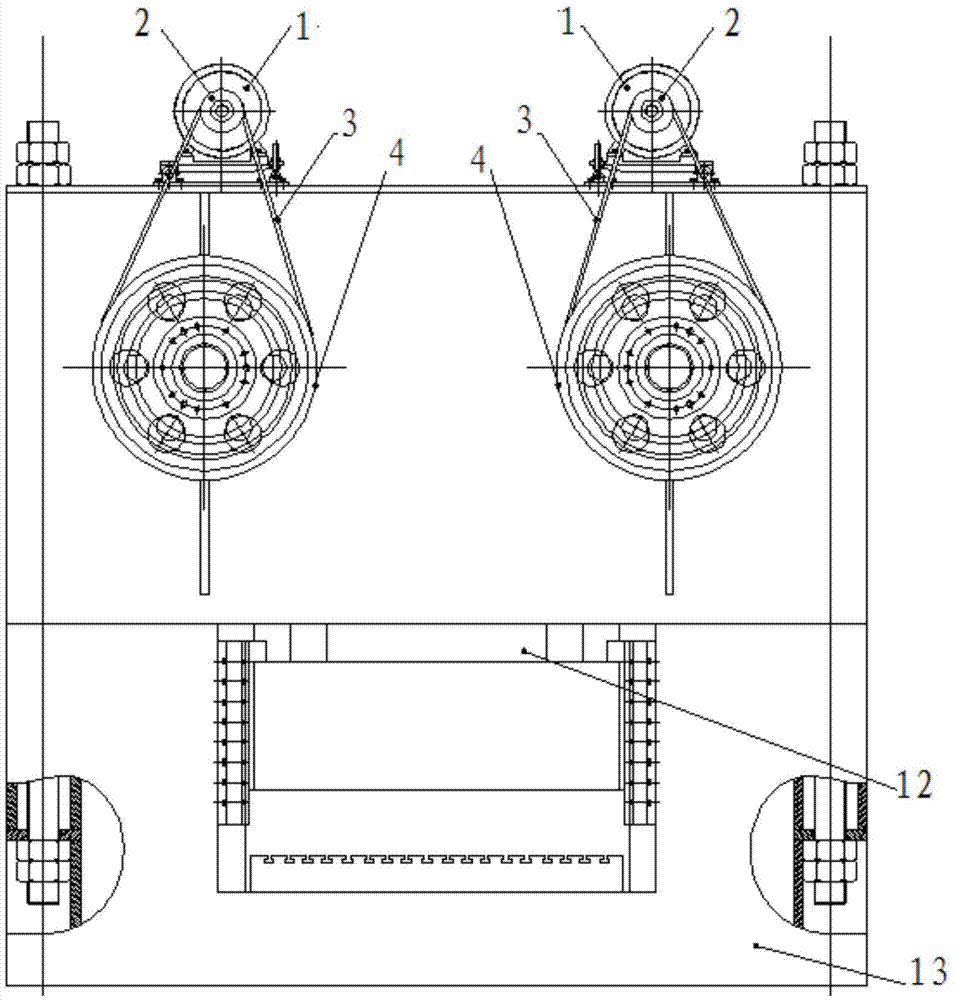

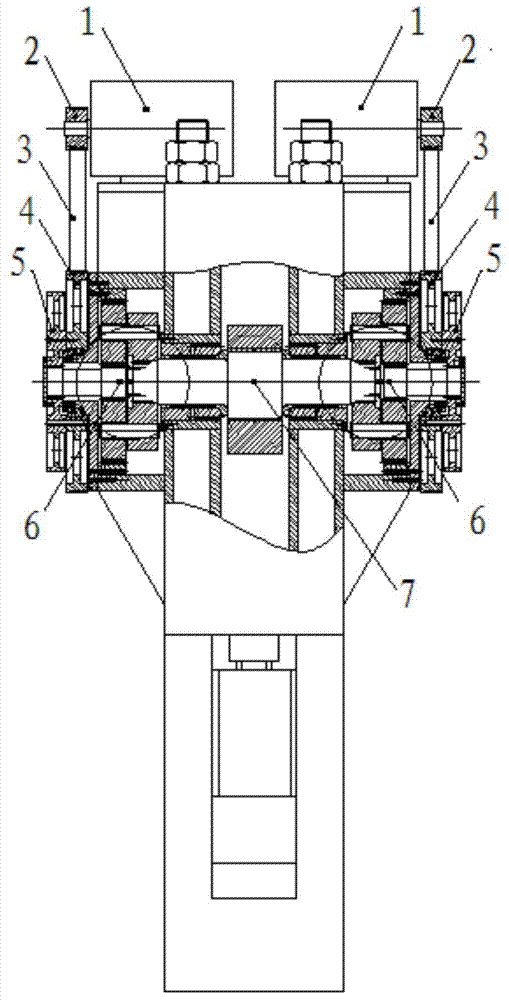

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , a transmission system suitable for large-tonnage servo direct-drive hot die forging presses, including four sets of transmission mechanisms and two sets of actuators. The four sets of transmission mechanisms adopt a multilateral layout and are symmetrically arranged around the press. Each set of transmission The mechanism includes a servo motor 1, and four servo motors 1 are symmetrically arranged on the hot forging press, which is the main power source for the hot forging press. The output shaft of each servo motor 1 is connected to the small pulley 2, and the small The pulley 2 can play the role of energy storage, the small pulley 2 is connected with the large pulley 4 through the transmission belt 3, the outer side of the large pulley 4 is connected with the brake 5, and the inner side of the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com