Method and system for preparing low-carbon olefin from crude oil

A low-carbon olefin and crude oil technology, applied in the field of low-carbon olefin preparation, can solve the problems of insufficient vaporization of crude oil, easy coking, low yield of low-carbon olefins, etc., to achieve insufficient gasification, high yield, and extended operation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 adopts the method for preparing light olefins from crude oil

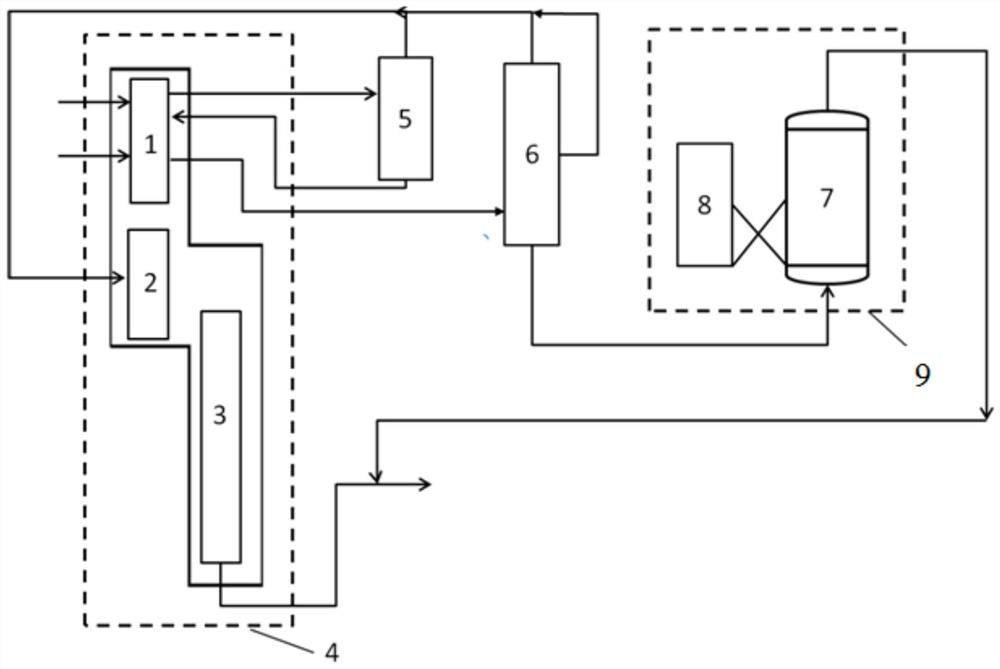

[0078] use figure 1 The system shown is performed, wherein the vaporization treatment unit employs a cyclone separator.

[0079] (1) The dehydrated and desalted crude oil is mixed with superheated steam in the first tube group of the convection section of the cracking furnace, and then preheated to obtain preheated crude oil. The weight ratio of superheated steam to crude oil is 0.75:1. Crude oil continues to be heated to 280°C to become preheated crude oil.

[0080] (2) The temperature of the preheated crude oil is 280°C, and it is sent to a cyclone separator with internals (the guide vane type cyclone separator is selected in this embodiment) for vaporization treatment to obtain the first vapor phase and the first liquid phase. Mutually. The separation efficiency of the cyclone separator is 98%, and the liquid phase in the first vapor phase after separation is 265mg / m 3 .

[0081] (3) Sen...

Embodiment 2

[0087] use figure 1 The system shown is carried out, wherein the vaporization separation unit adopts a cyclone separator.

[0088] (1) After the dehydrated and desalted crude oil is mixed with superheated steam in the first pipe group 1 of the convection section of the cracking furnace 4, the preheated crude oil is obtained. Crude oil continues to be heated to 315°C to become preheated crude oil.

[0089] (2) the temperature of the crude oil after preheating is 315 ℃, it is sent into the first cyclone separator 5 (the guide vane type cyclone separator is selected in the present embodiment) that has internal member to carry out vaporization separation and obtain the first vapor phase and first liquid phase. The separation efficiency of the first cyclone separator 5 is 98%, and the liquid phase in the first vapor phase after separation is 150mg / m 3 .

[0090] (3) Send the first liquid phase into the first tube group of the convection section of the cracking furnace for prehe...

Embodiment 3

[0096] use figure 1 The system shown is carried out, wherein the vaporization separation unit adopts a cyclone separator.

[0097] (1) After the dehydrated and desalted crude oil is mixed with superheated steam in the first pipe group 1 of the convection section of the cracking furnace 4, the preheated crude oil is obtained. Crude oil continues to be heated to 220°C to become preheated crude oil.

[0098] (2) The temperature of the preheated crude oil is 220°C, and it is sent into the first cyclone separator 5 with internals (the guide vane type cyclone separator is selected in this embodiment) for vaporization and separation to obtain the first gas phase and the second gas phase. a liquid phase. The separation efficiency of the first cyclone separator 5 is 98%, and the liquid phase in the first gas phase after separation is 100mg / m 3 .

[0099] (3) The first liquid phase is sent to the first tube group of the convection section of the cracking furnace for preheating to 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com