Method for preparing low-carbon olefin from petroleum hydrocarbon under reduced pressure conditions

A technology of low-carbon olefins and petroleum hydrocarbons, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve the problems of complex processing process, increase of production cost of low-carbon olefins, difficulty of low-carbon olefins to have market competitiveness, etc., to achieve The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

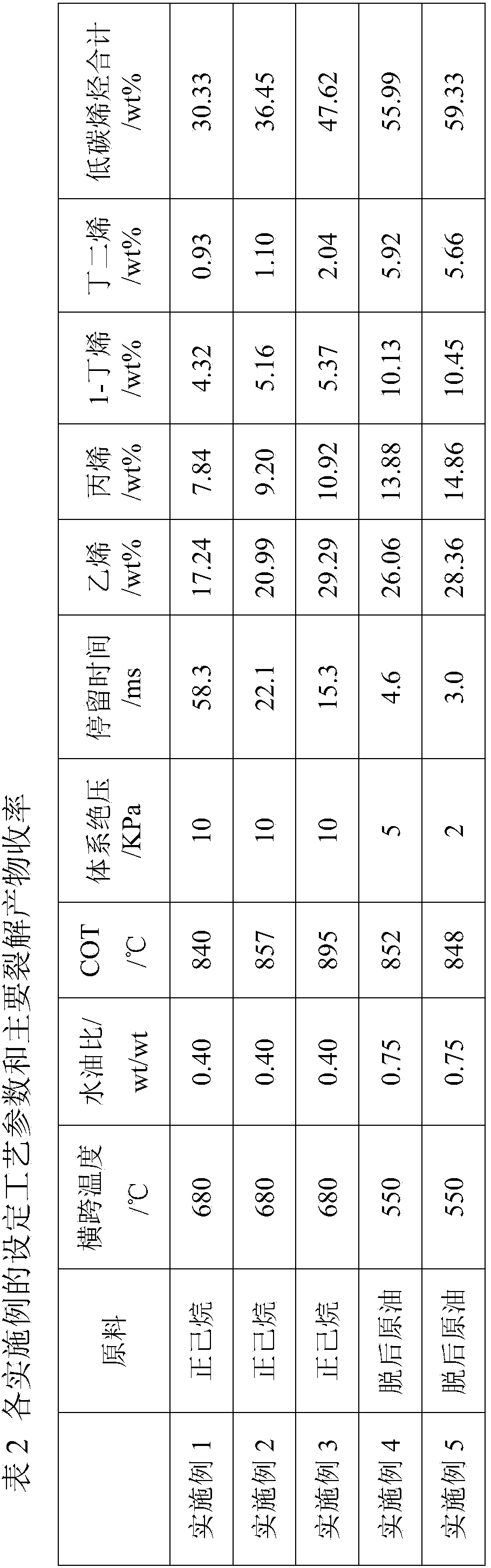

Embodiment 1-5

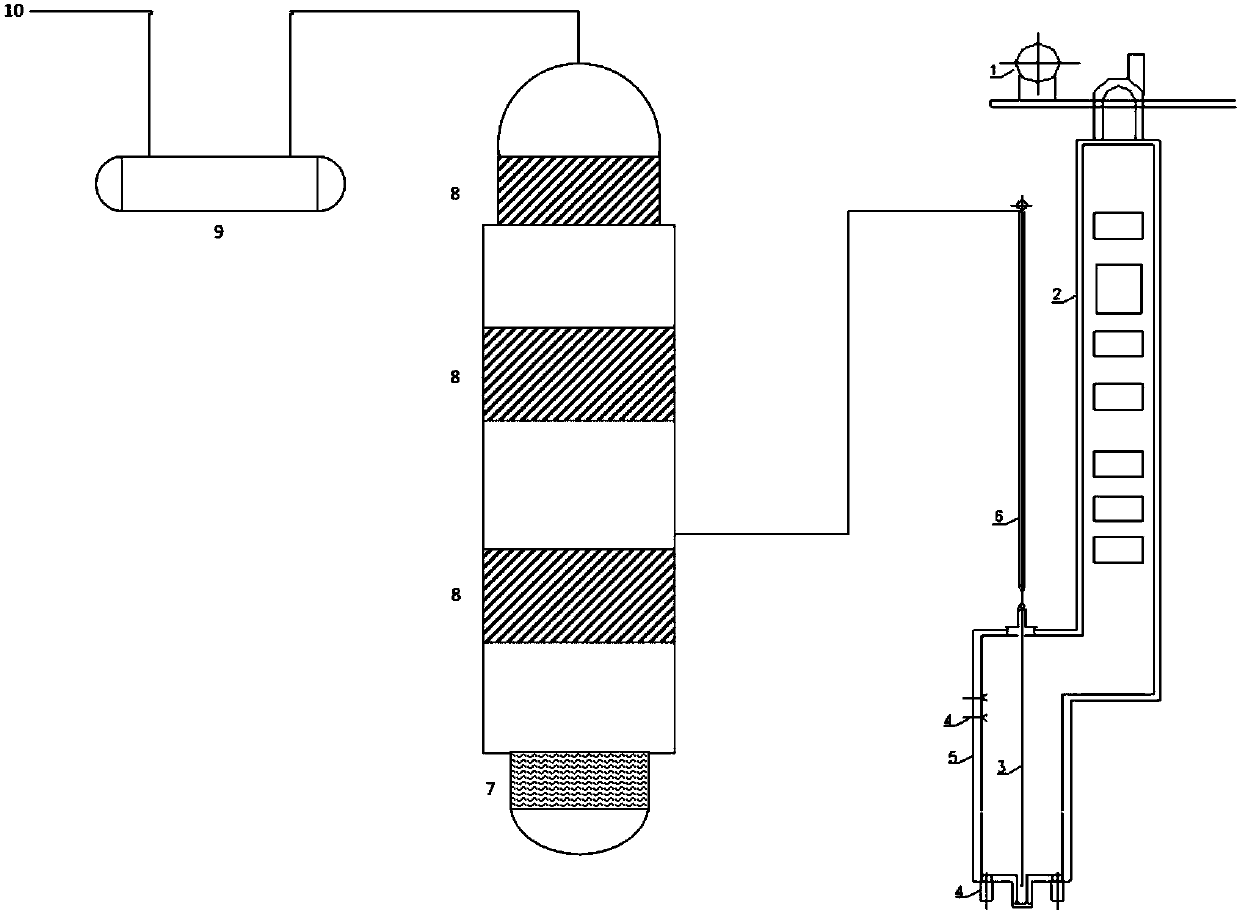

[0052] Connect the small-scale pyrolysis simulation device with a set of vacuum separation tower, such as figure 1 As shown, the device comprises a cracking furnace and a vacuum separation tower connected with the cracking furnace, and the cracking furnace includes a convection section 2, a radiation section 5 communicated with the convection section 2, a waste heat boiler 6 and a steam drum, and Multiple groups of radiant furnace tubes 3 vertically arranged in the radiant section; the decompression separation tower includes a decompression system 10, a reflux condenser 9 and a separation tower connected in sequence, and the middle part of the separation tower is connected with the cracking gas main pipe of the cracking furnace Generally speaking, multiple sets of tower internals 8 are arranged in the separation tower, and a bottom reboiler 7 is arranged at the bottom of the tower.

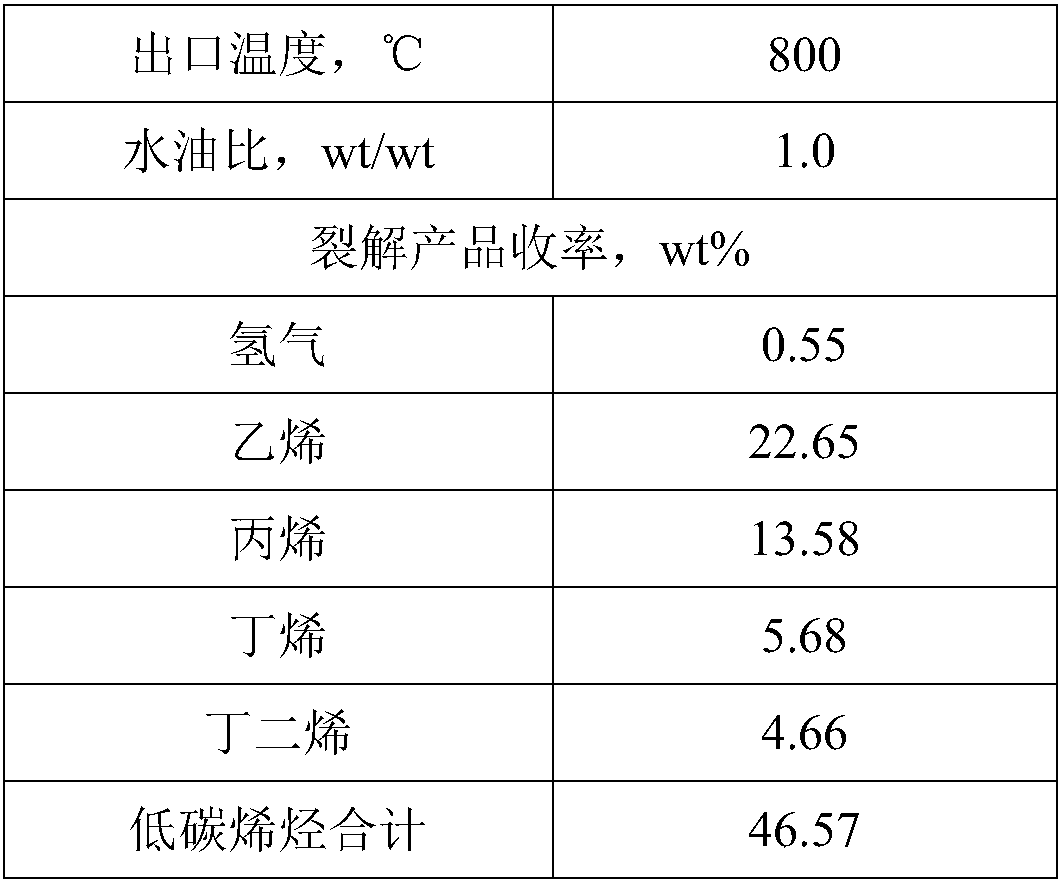

[0053] The method for preparing light olefins by cracking petroleum hydrocarbons under reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com