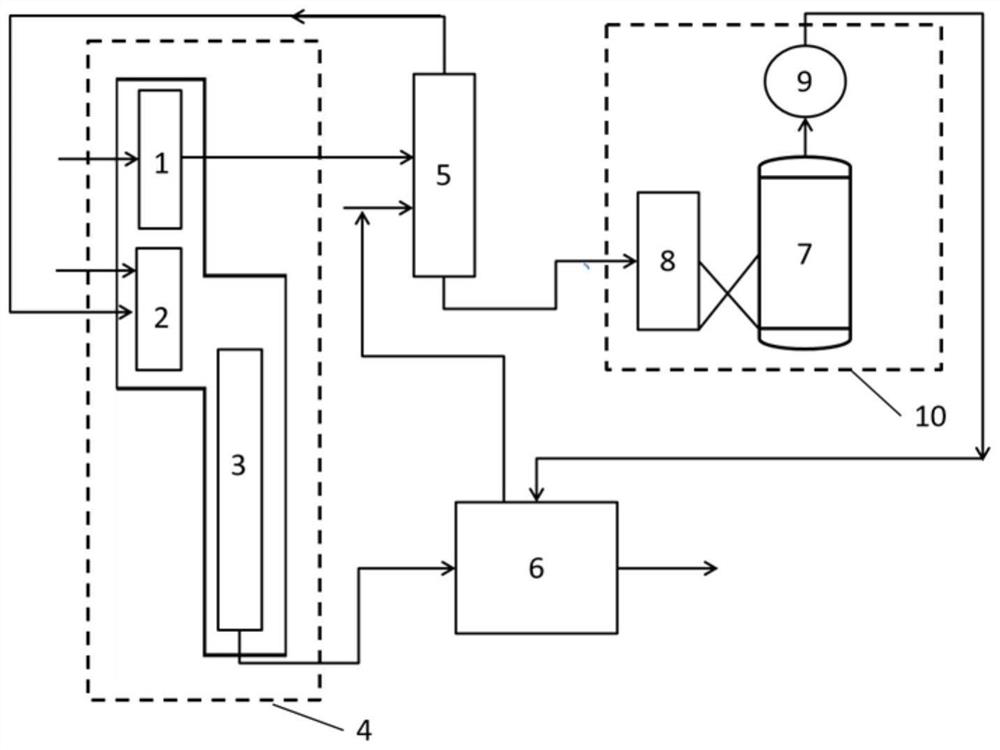

Method and system for preparing low-carbon olefin from crude oil

A low-carbon olefin and crude oil technology, applied in the field of low-carbon olefin preparation, can solve the problems of short equipment operation period, extended operation period, and easy coking, and achieve the effect of simplifying crude oil utilization route, extending operation period and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] (1) Send the crude oil to the first tube group of the convection section of the cracking furnace for preheating, and send it to the high-pressure extraction tower together with light hydrocarbons (propane), wherein, the crude oil is sent to the middle and upper part of the high-pressure extraction tower, and the light hydrocarbons are sent to the upper part of the high-pressure extraction tower. into the lower part of the high-pressure extraction tower for extraction, wherein the weight ratio of light hydrocarbons to crude oil is 6:1, the pressure of the extraction tower is 6MPa, the temperature of the extraction tower is 90°C, and light components are obtained at the top of the tower. Heavy components are obtained at the bottom of the tower;

[0092] (2A) Light components are mixed with water vapor and sent to the second tube group of the convection section of the cracking furnace, and then sent to the radiation section of the cracking furnace after being heated to the ...

Embodiment 2

[0097] (1) Crude oil is sent into the convection section first pipe group of cracking furnace and preheated, and light hydrocarbons (by weight, isobutane 5%, n-butane 95%) are sent into high-pressure extraction tower together, wherein , the crude oil is sent to the middle and upper part of the high-pressure extraction tower, and the light hydrocarbons are sent to the middle and lower part of the high-pressure extraction tower for extraction, wherein the weight ratio of light hydrocarbons and crude oil is 4:1, and the pressure of the extraction tower is 4.5MPa, The temperature of the extraction tower is 155°C, light components are obtained at the top of the tower, and heavy components are obtained at the bottom of the tower;

[0098] (2B) Reduce the pressure of the light components to 1MPa, and separate the gas phase components and liquid phase components; mix the liquid phase components with water vapor and send them to the convection section of the cracking furnace, and heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com