Laser detection type combustion chamber temperature detection device

A technology of laser detection and laser measurement, which is applied in measuring devices, optical radiation measurement, sensing radiation from gas/flame, etc., and can solve problems such as failure to receive laser signals, angle deviation of laser signals, damage to sensitive spectral components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The laser temperature detection device for the furnace of a power plant will be described in detail below in conjunction with the accompanying drawings.

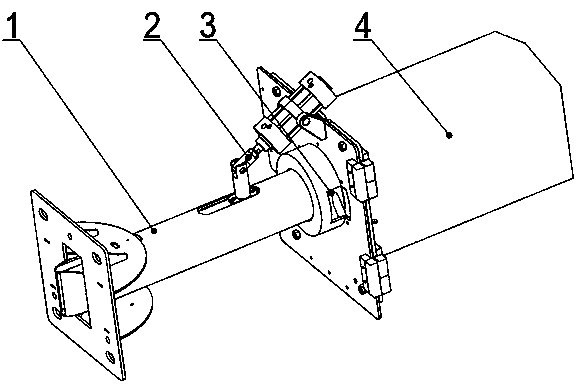

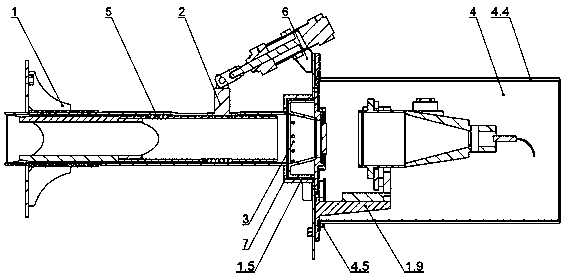

[0036] Such as figure 1 As shown in the present invention, a furnace temperature detection device using laser detection includes a bracket 1 , a decoking device 2 , a soot blowing cooling device 3 and a laser detection device 4 . The decoking device 2 , the soot blowing cooling device 3 and the laser detection device 4 are all installed on the bracket 1 .

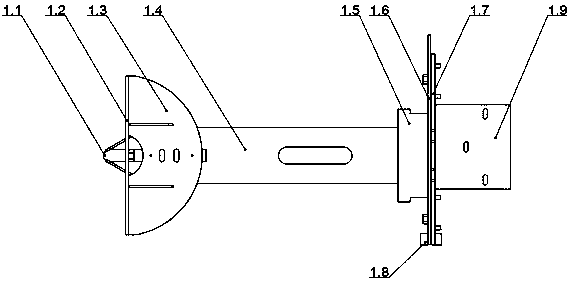

[0037] Such as figure 2 and image 3 As shown, the bracket 1 includes a fixed plate 1.2, a support plate 1.3, a seamless steel pipe 1.4, a cooling chamber 1.5, a mounting plate 1.6, a mounting plate 1.7, a hinge 1.8, and a mounting base 1.9; Through hole, the front end of the seamless steel pipe 1.4 is cut into a V-shaped structure, with baffles welded on both sides, and an approximately rectangular viewing port is formed at the V-shaped apex, and the V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com