Boiling bed hydrogenation reaction system and boiling bed hydrogenation process method

A technology of hydrogenation reaction and process method, which is applied in chemical instruments and methods, petroleum industry, hydrocarbon oil cracking, etc. It can solve the problems of affecting the effect of hydrogenation reaction, the difficulty of increasing the catalyst loading, and the limited increase of catalyst consumption, so as to achieve the improvement The effect of hydrogenation reaction, the effect of increasing the filling ratio and increasing the volume utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

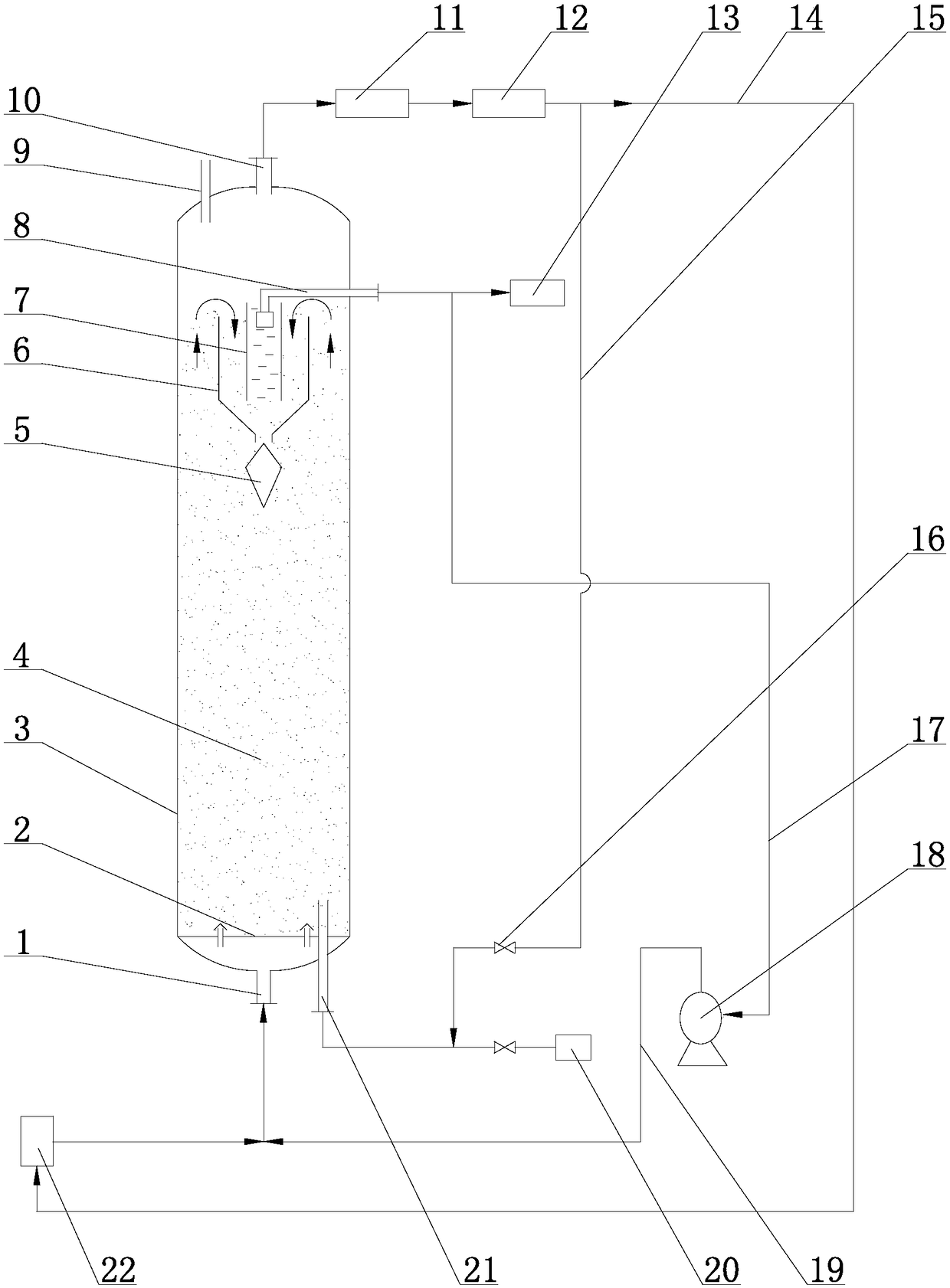

[0031] Example 1 used as figure 1 The ebullating bed hydrogenation reaction system shown. When the hydrogenation reaction is carried out in the reactor of the ebullated bed hydrogenation reaction system, the control valve 16 on the branch 15 between the outlet of the circulating hydrogen compressor and the catalyst discharge pipeline 21 is controlled to make the circulating hydrogen pass through the catalyst continuously or intermittently The discharge pipeline 21 enters the reactor cylinder 3 , and this operation method can effectively avoid the problem of coking of materials in the catalyst discharge pipeline 21 . The amount of circulating hydrogen entering the reactor barrel 3 from the catalyst evacuation pipeline 21 is controlled to be 0.2% of the total circulating hydrogen, while the material flow rate in the catalyst evacuation pipeline 21 is not lower than 0.1 m / s.

[0032] After testing, the catalyst discharge pipeline 21 can be kept unobstructed for a long period of ...

Embodiment 2

[0034] The structure of the ebullating bed hydrogenation reaction system used in embodiment 2 is as follows figure 1 As shown, it includes an ebullating bed hydrogenation reactor, a catalyst removal system, a hydrogen circulation system 12 and a reaction liquid phase effluent circulation system.

[0035] The bottom of the reactor cylinder 3 is provided with a raw material inlet 1 (the raw material includes liquid feedstock oil and hydrogen, which are fed through the reactor feed system 22), the top is provided with a catalyst inlet 9, a gas outlet 10, and the upper part is provided with a liquid outlet . The top in the reactor cylinder 3 is provided with a gas, liquid and solid three-phase separator, and a liquid discharge pipeline 8 is arranged in the liquid phase region of the three-phase separator, and the outlet of the liquid discharge pipeline 8 is the liquid outlet of the reactor cylinder 3, The liquid separated by the three-phase separator is passed into the reaction l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com