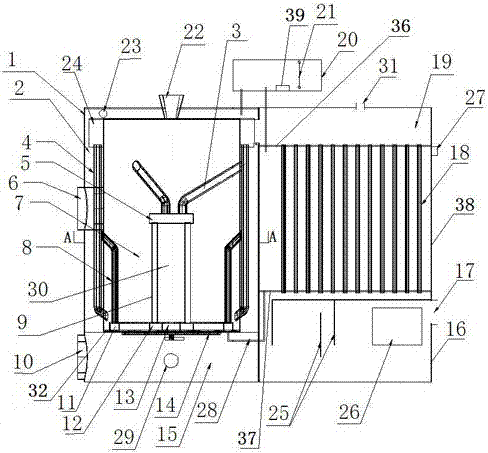

High Efficiency Cokeless Briquette Boiler

A coke-free, high-efficiency technology, applied in the field of boiler combustion, can solve the problems of high energy consumption energy utilization, easy coking and dust accumulation, low efficiency, etc., and achieve the effect of reducing emissions and reducing urban pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] During use, the molded coal falls into the combustion zone 7 through the feeding port 22, and the molded coal is ignited by artificial ignition.

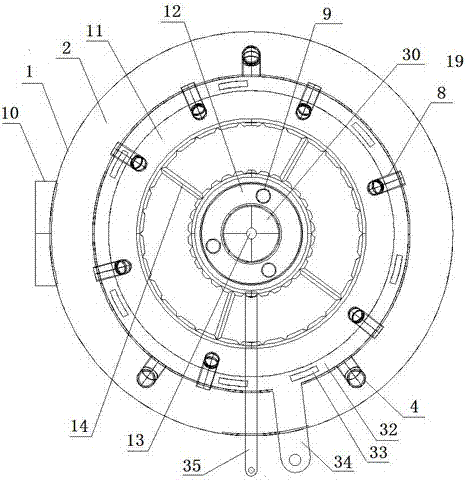

[0043] The external induced draft fan introduces air through the damper 29, and the gas enters the air chamber 30 from the ash chamber 15; then enters the combustion zone 7 through the gap between the inner water-cooled wall pipes 9, so that the molded coal can be fully burned.

[0044] Tap water enters the preheater 38 through the water inlet pipe 27, and then enters the outer water jacket 2, the inner and lower large water jacket 11 and the inner and lower small water jacket 12 through the water connecting pipe 28;

[0045] The water in the inner and lower small water jackets 12 enters the inner upper water jacket 5 through the inner water-cooled wall pipe 9, and then enters the outer water jacket 2 through the connecting pipe 3; Enter the outer water jacket 2;

[0046] The water in the outer water jacket 2 is supplied to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com