Center hole pressure accumulator non-static leak injector

A fuel injector and pressure accumulating technology, which is used in fuel injection devices, machines/engines, charging systems, etc., can solve the problem of high cleanliness requirements, unfavorable mass production of injectors, and complex injector structures, etc. problems, to achieve better sealing effect, is conducive to precise control, better fuel combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

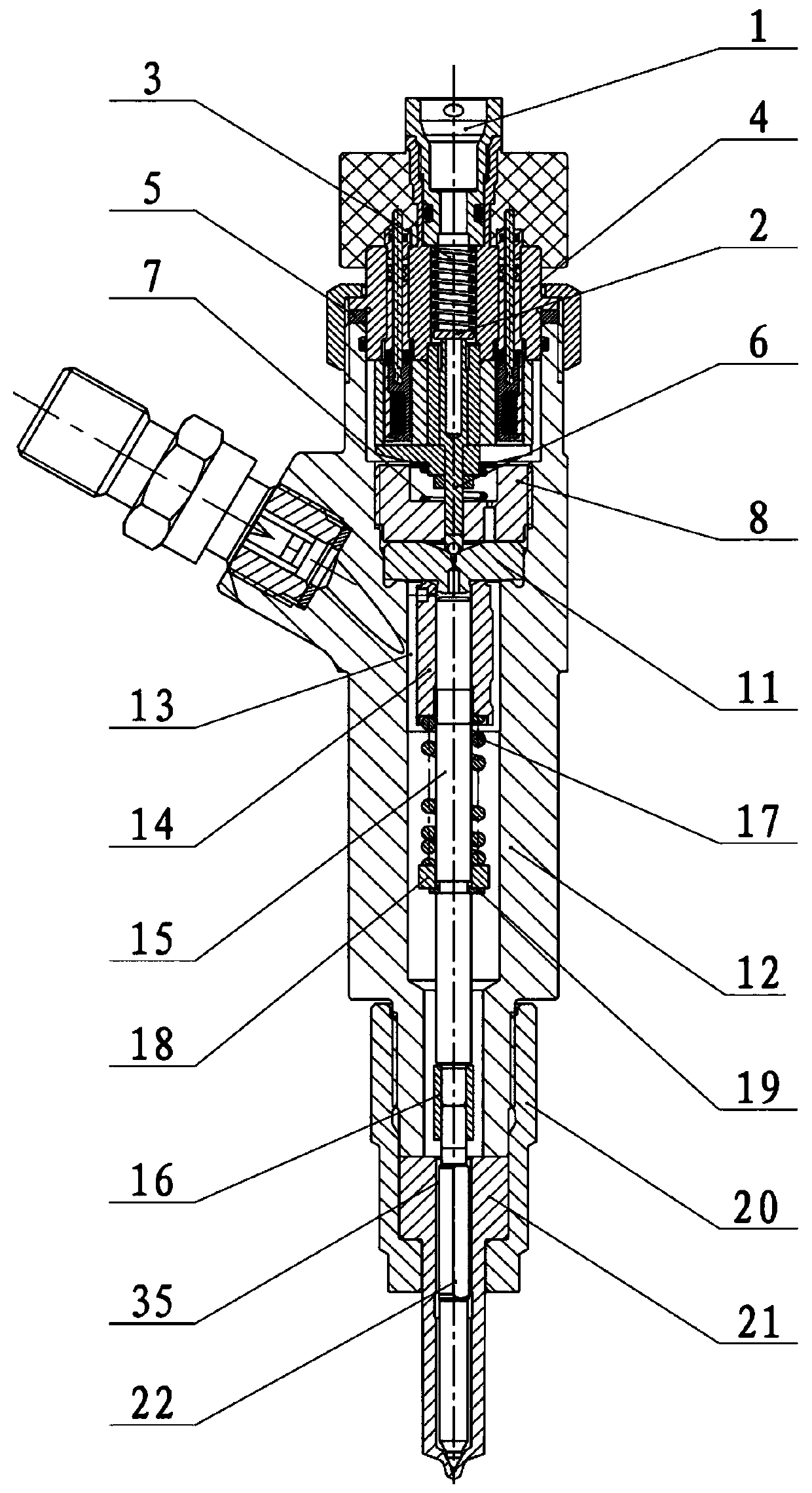

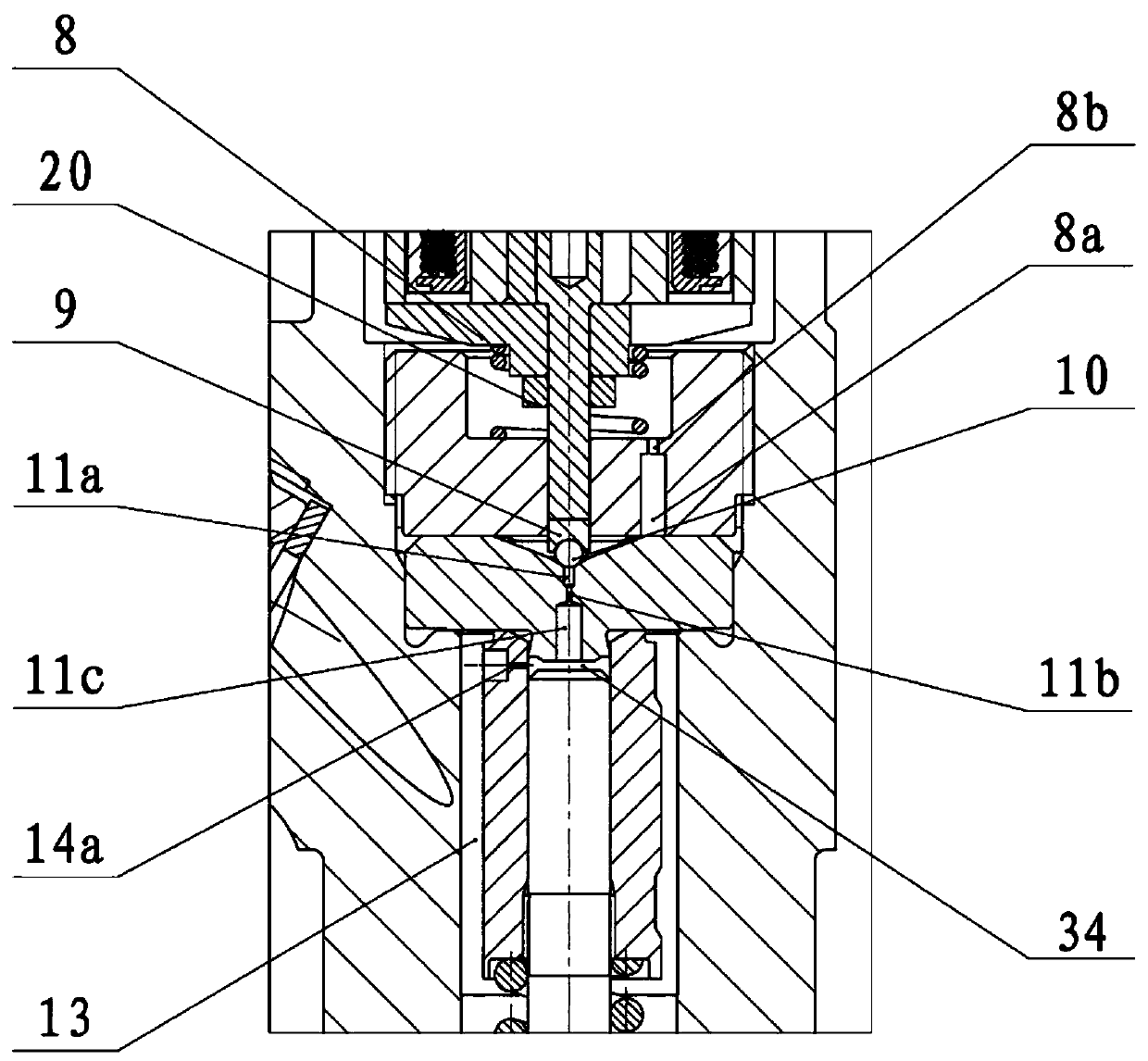

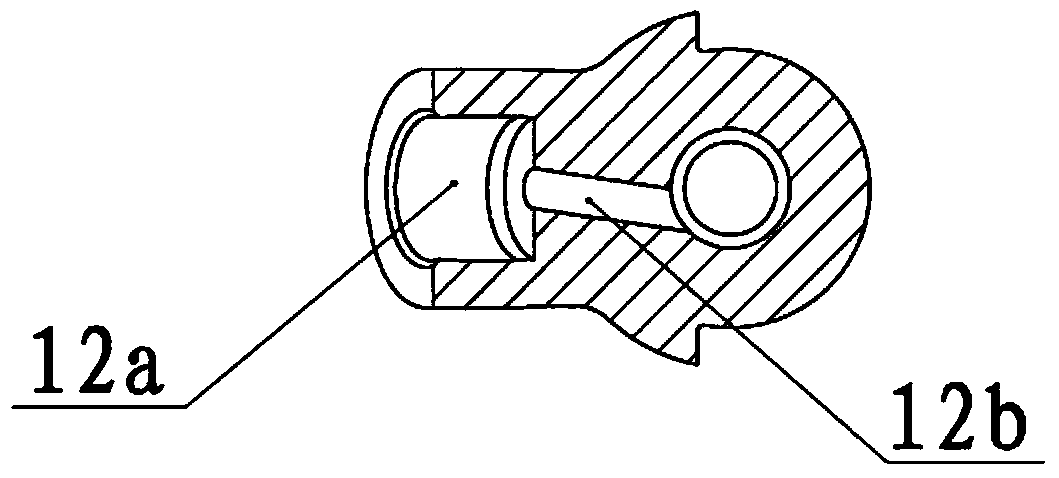

[0045] Such as Figure 1-4 As shown, the middle hole pressure accumulating non-static leakage fuel injector of the present invention includes a high-speed solenoid valve, a lock nut 8, a conical ball valve type switch valve, a control plunger couple, a fuel injector spring 17, a spring seat 18, The opening retaining ring 19, the injector body 12, the injector nozzle assembly and the injector tight cap 20; the high-speed solenoid valve is accommodated in the cavity at the upper end of the injector body 12, and is threadedly connected with the upper end of the injector body 12; The high-speed solenoid valve includes an oil return screw 1, a preload adjusting gasket 2, a solenoid valve spring 3, a magnetic head injection molding assembly 4, a solenoid valve needle assembly 6 and an armature return spring 7; the oil return screw 1 and the magnetic head The upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com