Shale oil diesel fraction single-stage serial hydrorefining method

A hydrorefining and shale oil technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems that motor fuel oil cannot be used directly, and the operating parameters are harsh, so as to reduce the concentration, improve the quality, The effect of reducing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

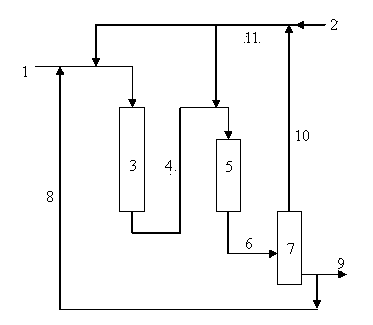

Image

Examples

Embodiment 1

[0031] In this example, the first reactor was filled with two catalysts, R-FF-26 and FF-26, the weight ratio of the two catalysts was 1:1, and the bed porosity was 0.50. The second reactor uses FF-26 hydrotreating catalyst developed and produced by Fushun Petrochemical Research Institute, and the bed porosity is 0.38. A part of the generated oil in the second reactor is recycled to the first reactor and directly mixed with the raw material shale oil diesel fraction for heat exchange, and the mixing ratio is raw material: generated oil = 2:1. The reaction process conditions and results are shown in Table 2.

Embodiment 2

[0033] Same as Example 1, except that the oil produced in the second reactor was not recycled back to the first reactor.

[0034] Example 1 Example 2 first reactor catalyst R-FF-26 / FF-26 R-FF-26 / FF-26 Process conditions temperature, ℃ 190 190 pressure, MPa 8.0 8.0 Hydrogen oil ratio 800:1 800:1 Airspeed, h -1 3.5 3.5 second reactor catalyst FF-26 FF-26 Process conditions temperature, ℃ 360 360 pressure, MPa 8.0 8.0 Hydrogen oil ratio 800:1 800:1 Airspeed, h -1 0.8 0.8 Produced oil N content, μg / g 154 300

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com