A kind of coal tar full-fraction ebullating bed hydrogenation method

A technology of whole distillate and coal tar, which is applied in the field of hydrogenation to achieve the effect of improving the effect of hydrogenation reaction, reducing investment and operating costs, and improving the mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

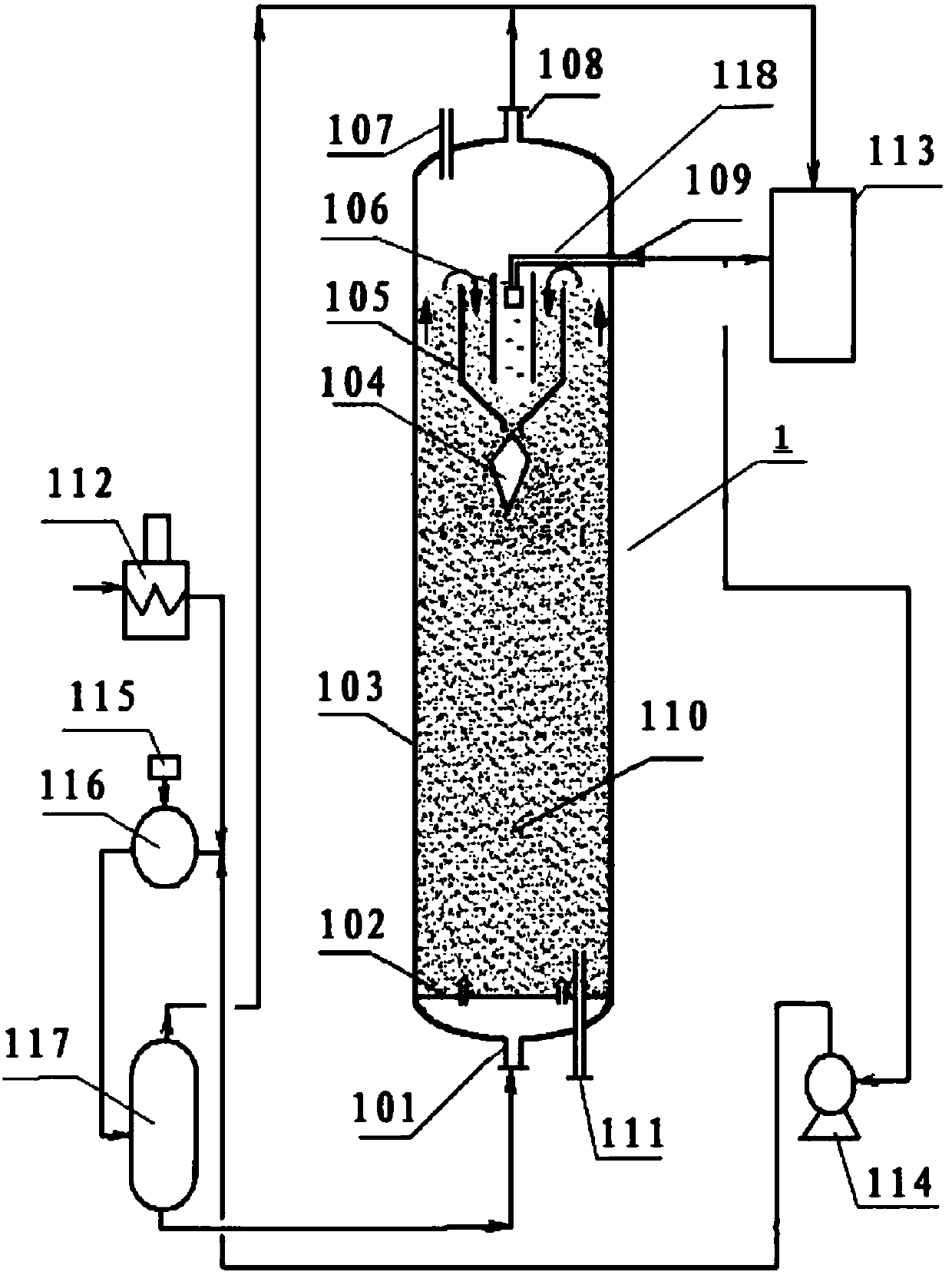

[0063] With the coal tar full distillate of table 1 as raw material, according to figure 1 The treatment method for hydrotreating:

[0064] (1) The whole fraction of coal tar is heated to 390°C, and mixed with the circulating oil of the ebullated bed reactor according to the volume mixing ratio of the full fraction of coal tar and circulating oil of 1:2;

[0065] (2) The mixture of step (1) is mixed with hydrogen in a hydrogen mixer to dissolve the hydrogen. The amount of hydrogen is determined according to the volume ratio (under standard conditions) of 260:1 to the whole fraction of coal tar. The hydrogen mixer uses conventional microbubbles Mixer, that is, hydrogen is dispersed into the oil phase through microbubble dispersion equipment, and then enters the gas-liquid separator;

[0066] (3) The gas phase at the top of the gas-liquid separator in step (2) enters the fixed-bed hydrogenation reactor from the top of the reactor, and the liquid phase dissolved in hydrogen at t...

Embodiment 2

[0076] With the coal tar full distillate of table 1 as raw material, according to figure 1 The treatment method for hydrotreating:

[0077] (1) The whole fraction of coal tar is heated to 390°C, and mixed with the circulating oil of the ebullated bed reactor according to the volume mixing ratio of the full fraction of coal tar and circulating oil of 1:2;

[0078] (2) The mixture of step (1) is mixed with hydrogen in a hydrogen mixer to dissolve hydrogen. The amount of hydrogen is determined according to the volume ratio (under standard conditions) of 600:1 to the whole fraction of coal tar. The hydrogen mixer uses conventional microbubbles Mixer, that is, hydrogen is dispersed into the oil phase through microbubble dispersion equipment, and then enters the gas-liquid separator;

[0079] (3) The gas phase at the top of the gas-liquid separator in step (2) enters the fixed-bed hydrogenation reactor from the top of the reactor, and the liquid phase dissolved in hydrogen at the b...

Embodiment 3

[0087] With the coal tar full distillate of table 1 as raw material, according to figure 1 The treatment method for hydrotreating:

[0088] (1) The whole fraction of coal tar is heated to 390°C, and mixed with the circulating oil of the ebullated bed reactor according to the volume mixing ratio of the full fraction of coal tar and circulating oil of 1:2;

[0089](2) The mixture of step (1) is mixed with hydrogen in a hydrogen mixer to dissolve hydrogen. The amount of hydrogen is determined according to the volume ratio (under standard conditions) of 200:1 to the whole fraction of coal tar. The hydrogen mixer uses conventional microbubbles Mixer, that is, hydrogen is dispersed into the oil phase through microbubble dispersion equipment, and then enters the gas-liquid separator;

[0090] (3) The gas phase at the top of the gas-liquid separator in step (2) enters the fixed-bed hydrogenation reactor from the top of the reactor, and the liquid phase dissolved in hydrogen at the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com