Fluidized bed hydrogenated reactor and fluidized bed hydrogenating method

A technology of hydrogenation reactor and fluidized bed, which is applied in the petroleum industry, processing with moving solid particles, and processing hydrocarbon oil, etc., can solve the problems of easy reaction coking, low utilization rate of the reactor, and not too much catalyst consumption, etc. Improve the volume utilization rate, enhance the effect of hydrogenation reaction, and improve the effect of separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

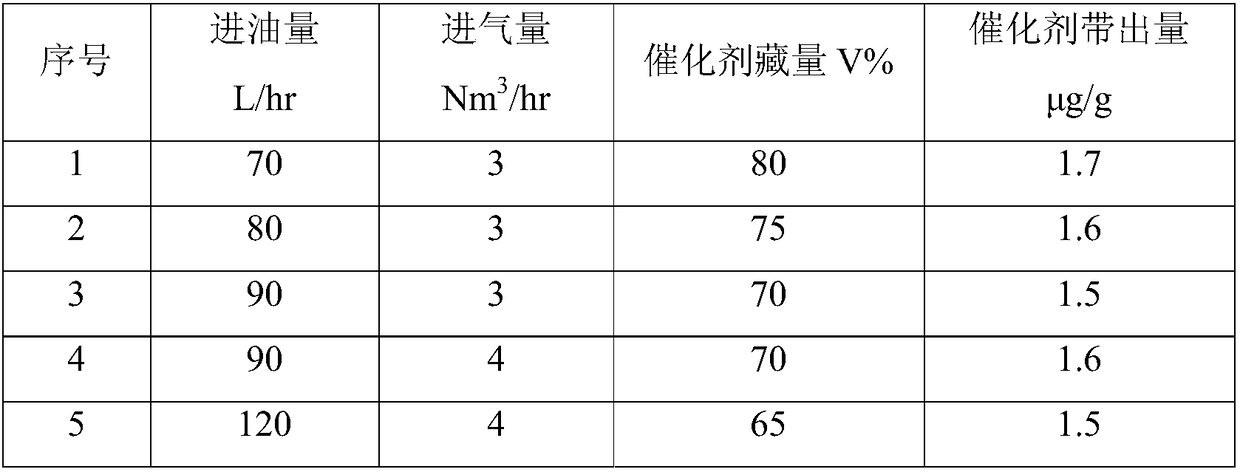

Embodiment 1

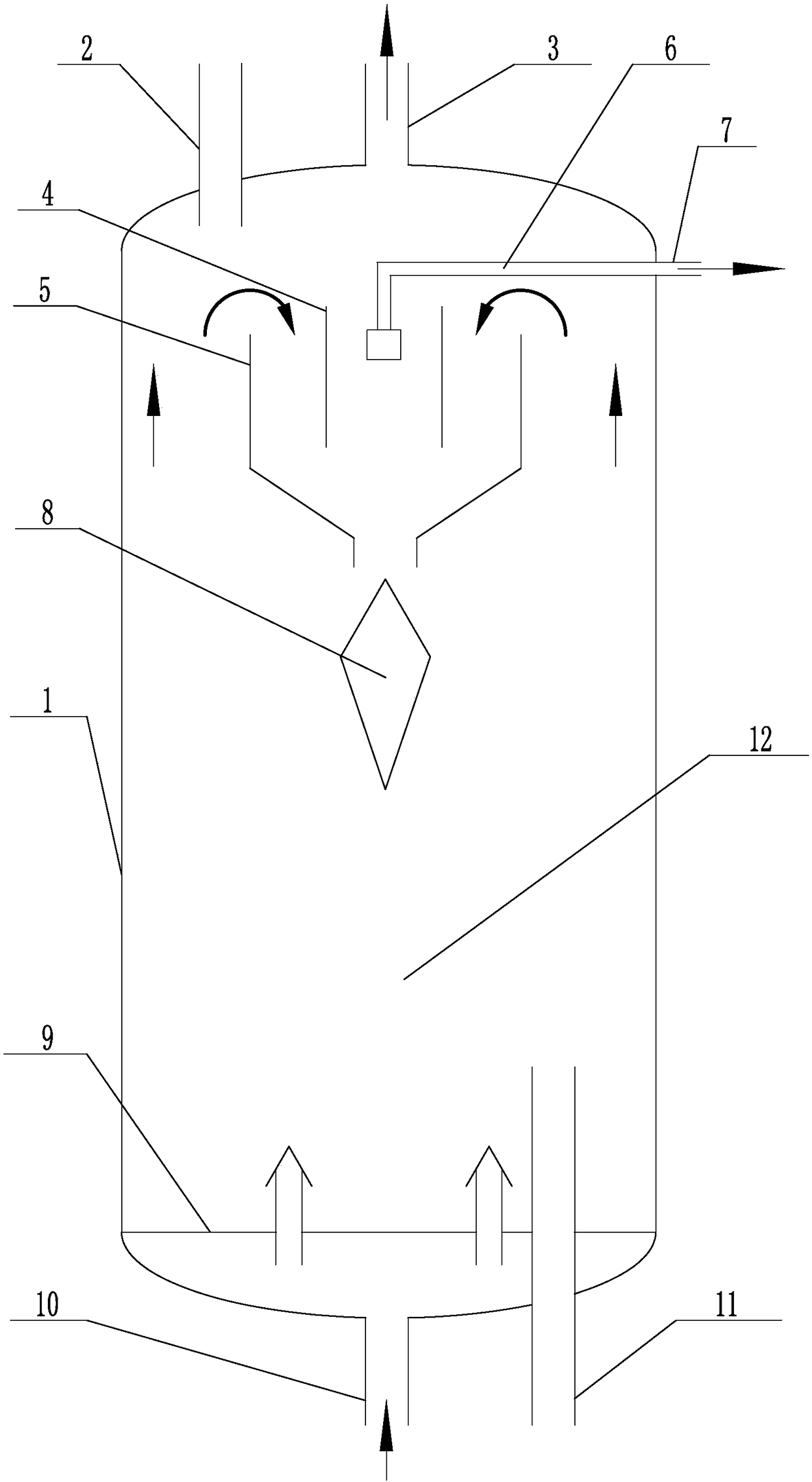

[0037] Such as figure 1 As shown, the fluidized bed hydrogenation reactor of the present invention includes a shell 1, the top of the shell 1 is provided with a catalyst inlet 2 and a gas outlet 3, and the upper part of the shell 1 is provided with a three-phase separator, and the three-phase separator It includes two concentric cylinders with different inner diameters, that is, the inner cylinder 4 and the outer cylinder 5, the upper and lower ends of the inner cylinder 4 and the outer cylinder 5 are all open, the upper end opening of the outer cylinder 5 is lower than the upper end opening of the inner cylinder 4, and the outer cylinder 4 The lower opening of the cylinder 5 is lower than the lower opening of the inner cylinder 4. The upper part of the outer cylinder 5 is a straight section, and the lower part of the outer cylinder 5 is a frustum-shaped contraction section. The lower opening of the contraction section is the lower opening of the outer cylinder 5. The inner cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com