Boiling bed reactor

A fluidized bed reactor and the technology of the reactor, which are applied in the fluidized bed field, can solve the problems of not too much catalyst dosage, low utilization rate of the reactor, and increased catalyst amount, etc., and achieve improved hydrogenation reaction effect, good separation effect, Avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

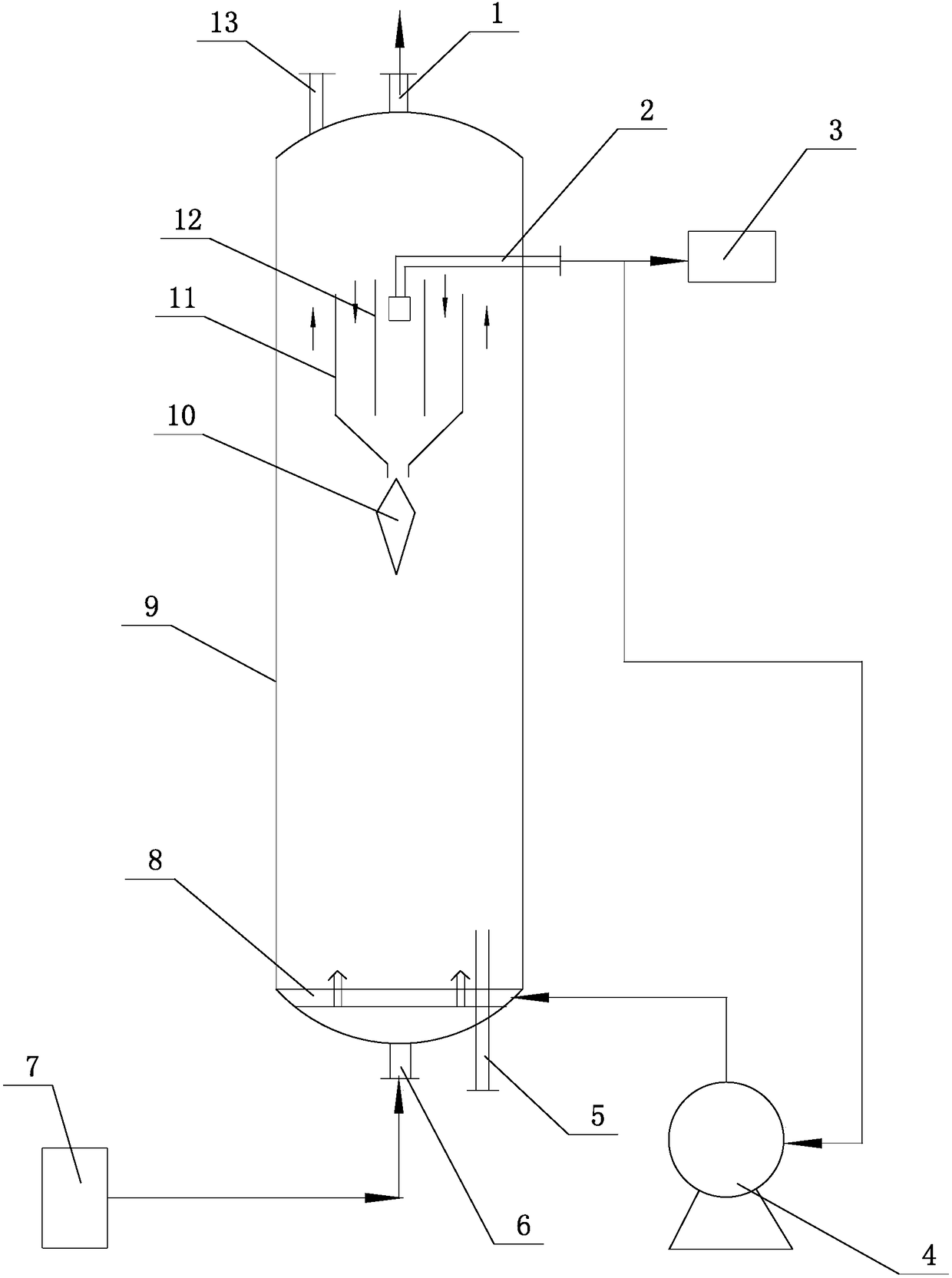

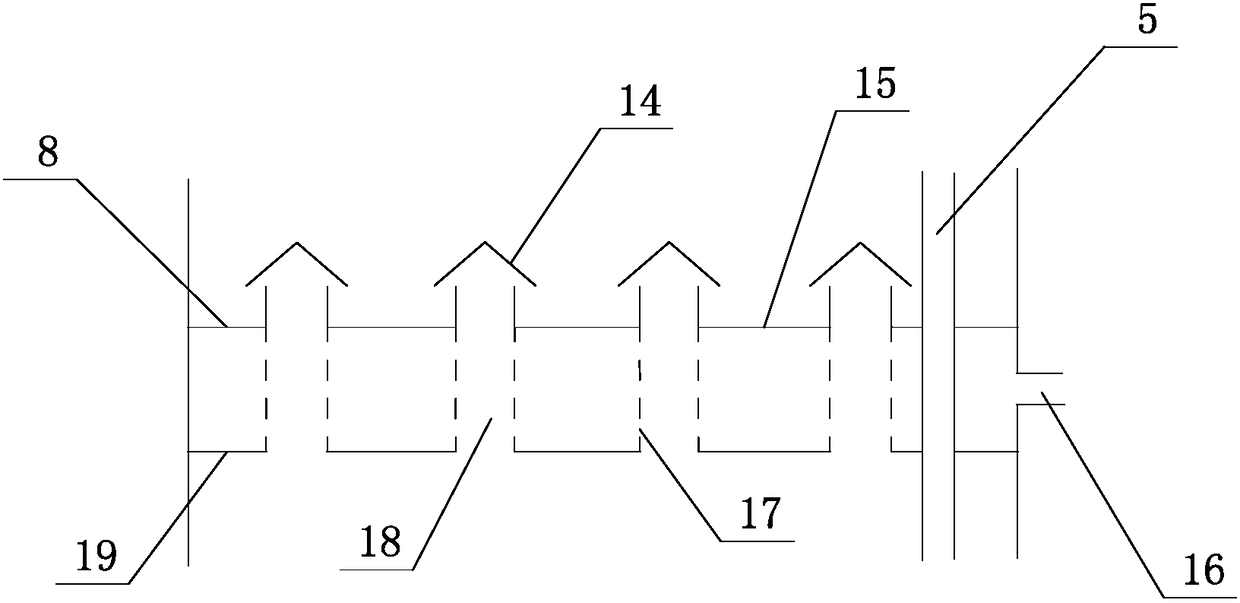

[0026] Such as Figure 1-2 As shown, the ebullating bed reactor of the present invention includes a reactor cylinder 9, the upper end of the reactor cylinder 9 is respectively provided with a catalyst inlet 13 and a gas outlet 1, and the lower end of the reactor cylinder 9 is provided with a material inlet 6 and a catalyst Outlet 5, a three-phase separator is arranged on the upper side of the reactor cylinder 9, and a gas-liquid distributor 8 is arranged on the lower side of the reactor cylinder 9, and the gas-liquid distributor 8 includes a material distribution pipe 18, an upper tower The tray 15 and the lower tray 19, the upper tray 15 and the lower tray 19 form a double-layer tray structure, and the double-layer tray structure of the gas-liquid distributor 8 is tightly fixed on the inner wall of the reactor cylinder 9, and the upper tower A gap is formed between the tray 15 and the lower tray 19, the material distribution pipe 18 runs through the upper tray 15 and the lowe...

Embodiment 2

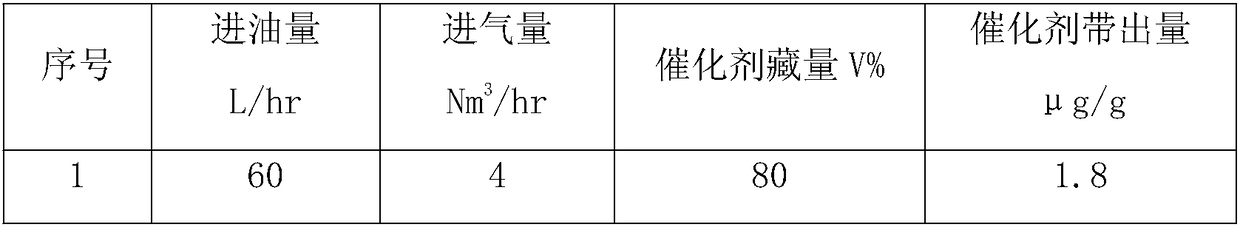

[0036] On the basis of Example 1, the separation effect of the three-phase separator is simulated by using a cold model. The size of the cold mold device is: the inner diameter of the reactor cylinder 9 is 200mm, the height of the reactor cylinder 9 is 3500mm, the height of the three-phase separator is 400mm, the diameter of the straight cylinder section of the outer cylinder 11 of the three-phase separator is 300mm, and the inner cylinder 12 The annular gap distance between the outer cylinder 11 and the outer cylinder 11 is 80mm, the height difference between the upper end of the inner cylinder 12 and the upper end of the outer cylinder 11 is 60mm, the gap between the lower end opening of the inner cylinder 12 and the contraction section of the outer cylinder 11 is 60mm, and the outer cylinder 11 The diameter of the opening at the lower end of the contraction section is 90 mm, and the contraction angle (the acute angle included angle between the straight tube section and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com