Hydrogenation method of phthalate compound

A technology of phthalic acid ester and said phthalic acid ester, which is applied in the field of hydrogenation of phthalic acid ester compounds, can solve the problems such as the compound hydrogenation reaction cannot be carried out smoothly, the hydrogen permeability is reduced, the raw material yield is decreased, and the like, To achieve the effect of improving hydrogenation reaction performance, improving reactivity and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0079] Meanwhile, according to another exemplary embodiment of the present invention, the hydrogenation method includes: reacting a phthalate compound with hydrogen in the presence of a hydrogenation catalyst and an alcohol having at least two carbon atoms.

[0080] The reaction object of the hydrogenation method according to the present invention is a phthalate compound, and hydrogen is added to the benzene ring of the phthalate compound by a hydrogenation reaction to thus be converted into the corresponding phthalate compound Cyclohexane dicarboxylate compound.

[0081] The phthalate compound mixed with the alcohol may be the same as in the above-mentioned exemplary embodiment.

[0082] The above-mentioned phthalate compound can be obtained by performing an esterification reaction of an acid (such as phthalic acid, terephthalic acid, isophthalic acid or an anhydride thereof) with an alcohol. After the above esterification reaction, in order to neutralize the catalyst used i...

Embodiment 1

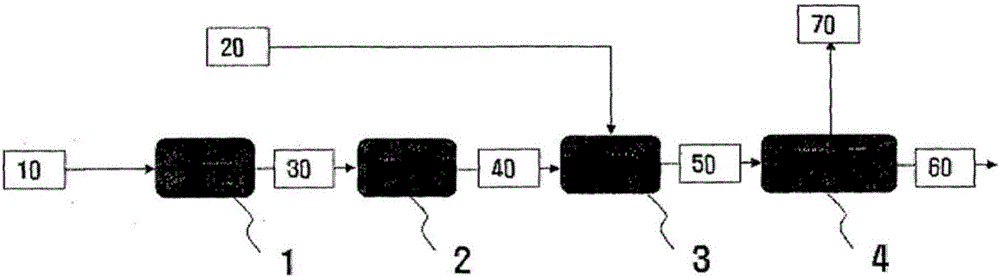

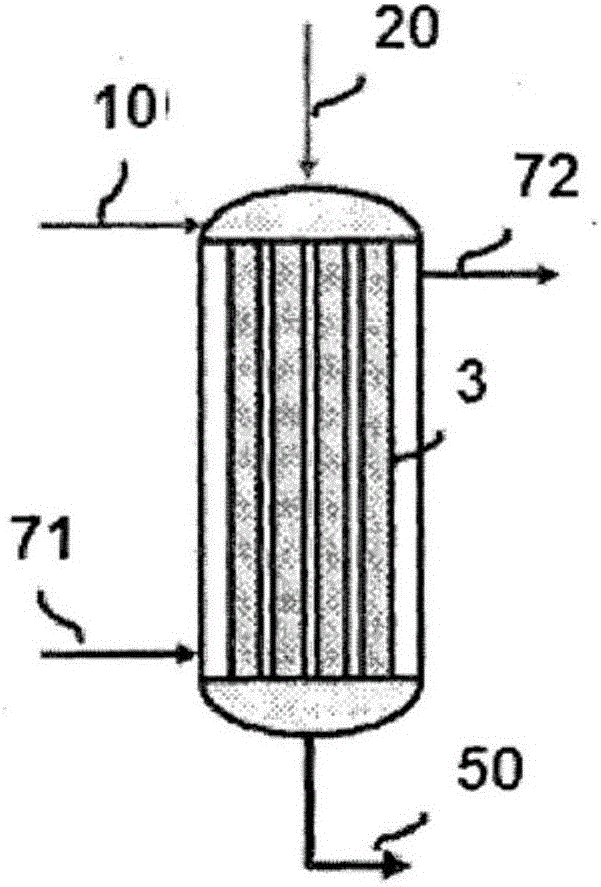

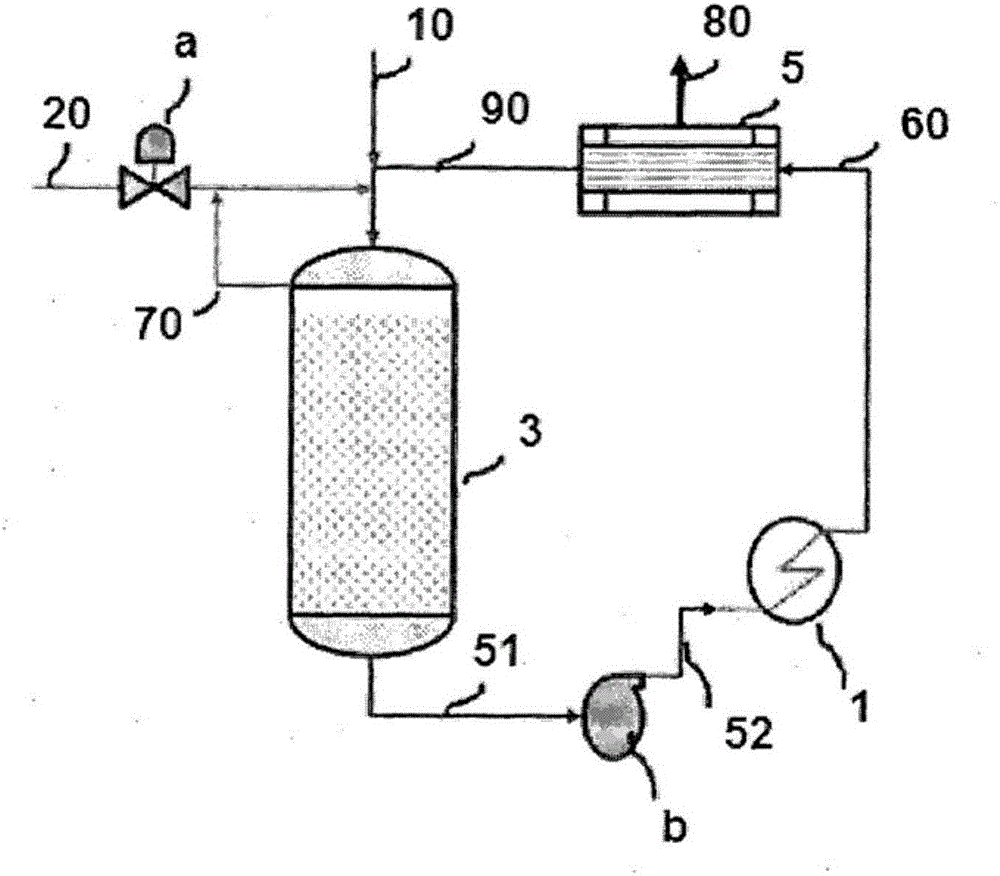

[0111] use figure 1 and 2 The reaction equipment for the hydrogenation reaction of phthalate compounds.

[0112] First, based on 100 parts by weight of dioctyl terephthalate (DOTP, purity: 99%), after raising the pressure of DOTP to 150 bar, the viscosity of DOTP added to the reactor was reduced to 4.62cP by a heat exchanger, Then, DOTP was injected together with hydrogen into a reactor filled with a ruthenium (Ru) catalyst.

[0113] The flow rate of injected DOTP was 9.6 kg / hr, and hydrogen was injected so that the molar ratio of hydrogen to DOTP became 5 moles.

[0114] As a reactor, a single tube having the same size as that used in a multi-tubular reactor was used, and the length of the catalyst-filled tube portion was 1.5 m in total. In addition, the hydrogenation reaction was carried out while maintaining the temperature by controlling the heat generated in the reactor using hot oil.

[0115] The catalyst used in the reactor was a ruthenium (Ru) catalyst, and a cylin...

Embodiment 2

[0117] A hydrogenation reaction was performed in the same manner as in Example 1 except that the viscosity of DOTP charged in the reactor in Example 1 was 3.55 cP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com