Fluidized bed hydrogenation reaction equipment and fluidized bed hydrogenation method

A technology for hydrogenation reaction and hydrogenation reactor, which is used in chemical instruments and methods, petroleum industry, refining to remove heteroatoms, etc., can solve the problems that catalysts are difficult to reach boiling state, easy to react and coke, and the amount of catalysts can not be too much, etc. , to achieve the effect of improving hydrogenation reaction effect, improving volume utilization rate and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

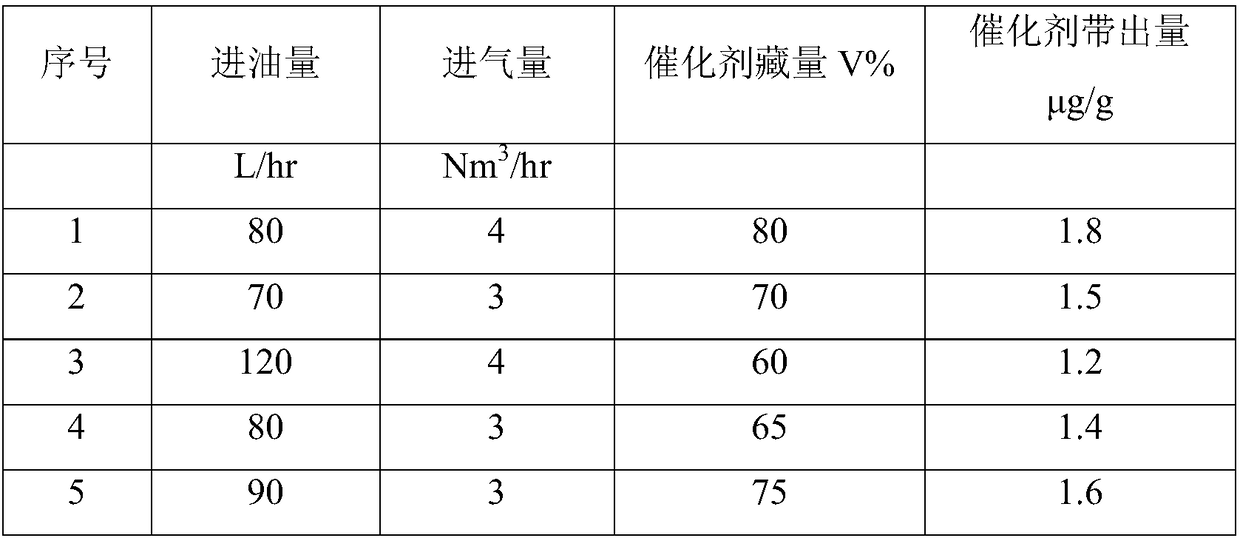

Examples

Embodiment Construction

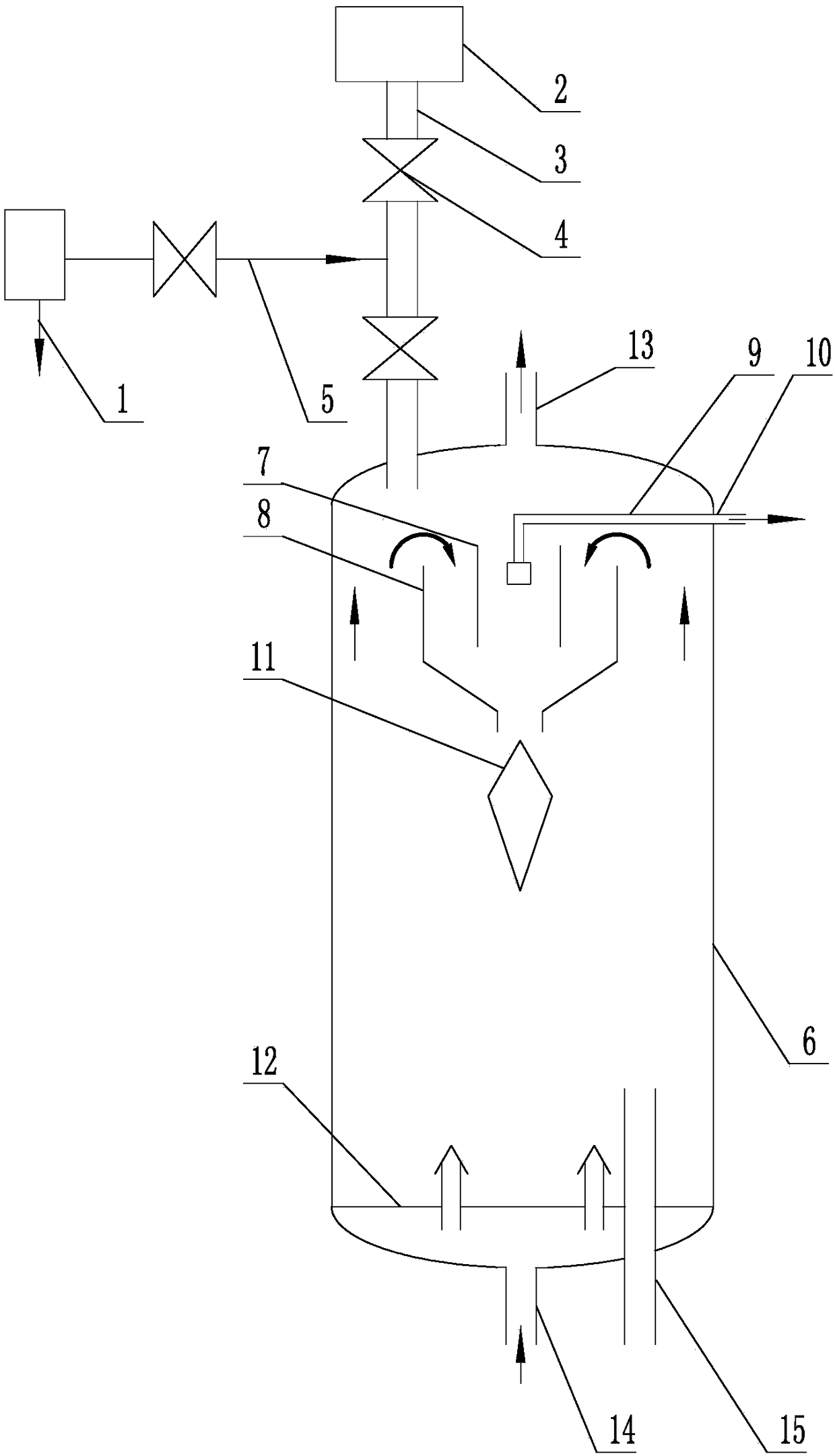

[0039] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0040] Such as figure 1 As shown, the ebullated bed hydrogenation reaction equipment of the present invention includes an ebullated bed hydrogenation reactor, a catalyst adding system and a dosing pipeline 1, wherein the catalyst adding system includes a catalyst storage tank 2 and a catalyst storage tank 2 connected with The catalyst delivery pipeline 3 in the internal space of the ebullating bed hydrogenation reactor, at least two valves 4 are arranged on the catalyst delivery pipeline 3, and the catalyst delivery pipeline 3 between the two valves 4 and the dosing pipeline 1 adopt anti- The hydrogen sulfide leakage pipeline 5 is connected, and at least one valve 4 is arranged on the hydrogen sulfide leakage prevention pipeline 5 . The dosing pipeline 1 is the outlet pipeline of the new hydrogen compressor or the outlet pipeline of the raw oil pump. The ebull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com