Automatic valve core component and differential pressure-independent type flow control valve

A technology for flow control valves and automatic valves, applied in the field of balance valves, which can solve the problems of flow control valves without filtering function, complex structure of flow control valves, and increased pipeline system resistance, etc., to achieve compact structure, simple structure, and adjustment and control accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

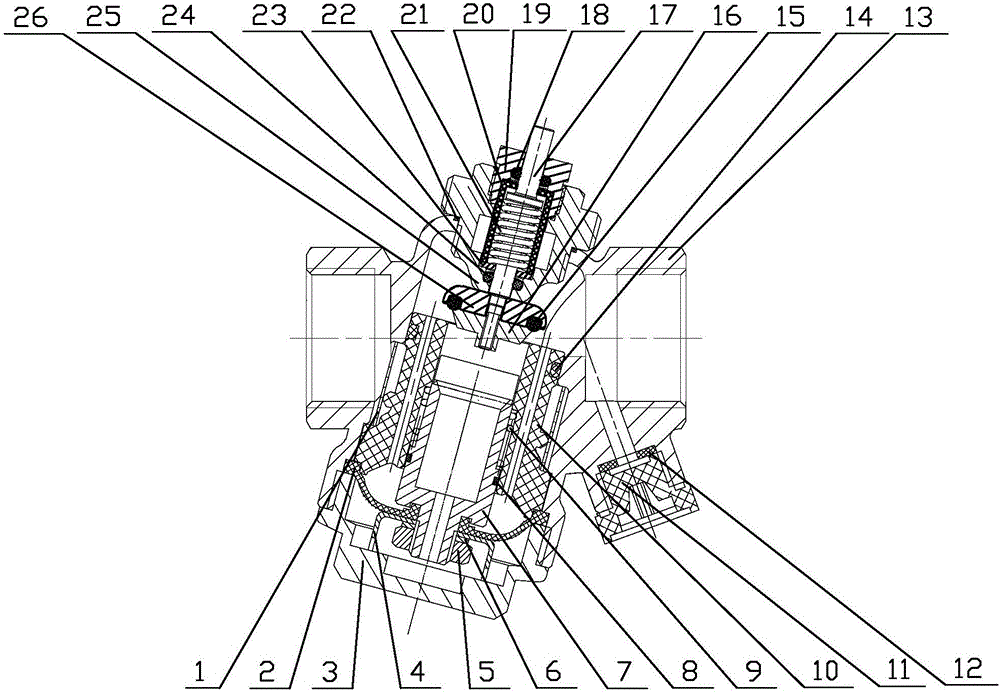

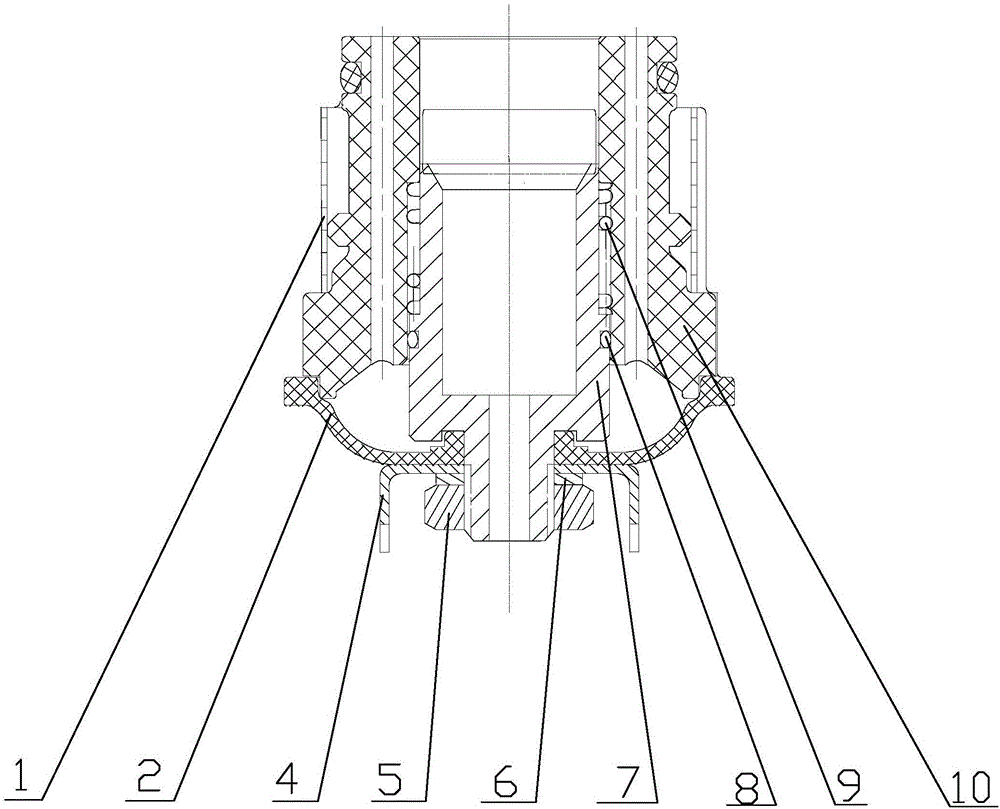

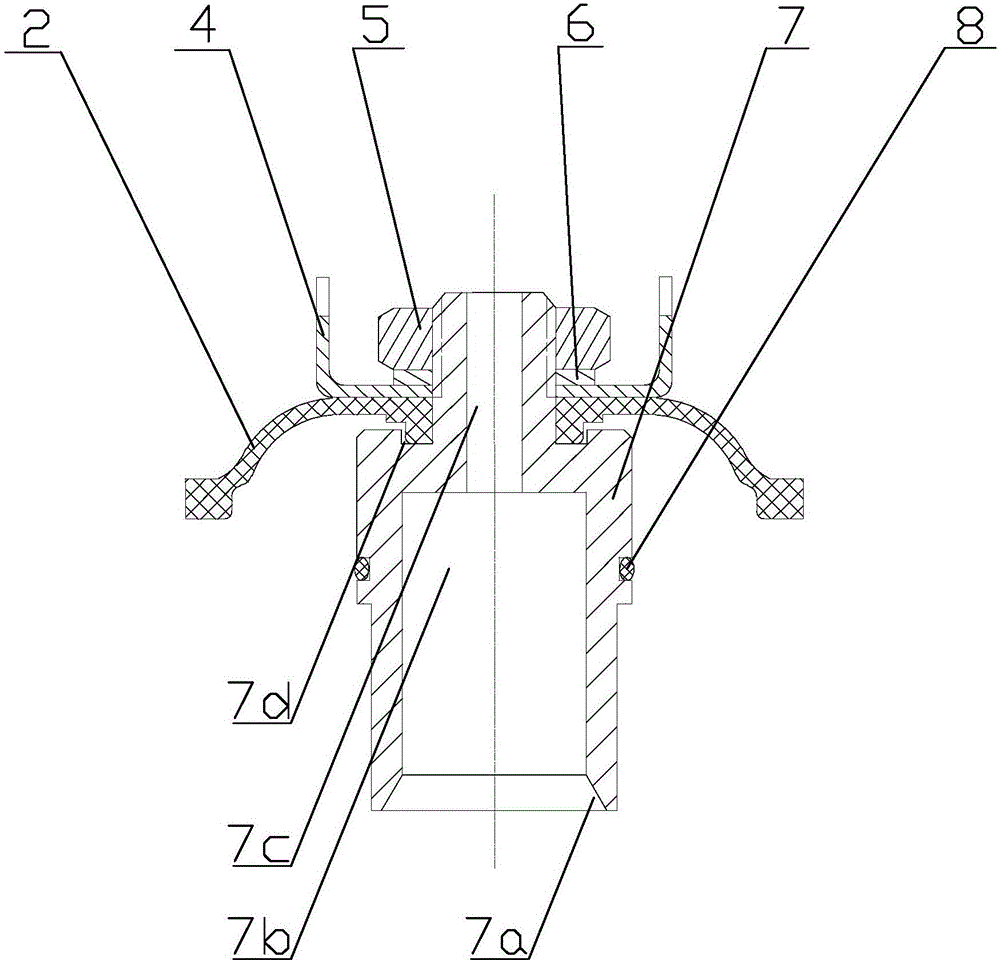

[0043] In this embodiment, a differential pressure independent flow control valve is combined with figure 1 , including an automatic valve core assembly, a lower valve cover 3, a valve body 13, a linear disc 16, a valve stem 17, an upper valve cover 25 and a support plate 26, combined figure 2 , image 3 and Figure 4 , the automatic spool assembly includes a pressure-sensitive diaphragm 2, a pressing disc 4, an adjusting spool 7 and a spool sleeve 10, combined Figure 5 and Figure 6, the valve core sleeve 10 is a cylindrical multi-boss sleeve structure, and its upper end surface is provided with a water guide hole 10b, and the water guide hole 10b directly leads to a stepped hole on its lower end surface, and the stepped hole and the middle part of the valve core sleeve 10 are provided with a rectangular groove communicate with each other to ensure the passage of the upstream medium; the regulating valve core 7 is a stepped cylindrical sleeve structure, and its upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com