Intelligent large cement foaming machine

A cement foaming, large-scale technology, applied in the direction of ceramic molding machines, cement mixing devices, chemical instruments and methods, etc., can solve the problems of no filtering function, no noise reduction protection, no sampling detection, etc., to achieve convenience The work of conveying cement, saving labor intensity, and increasing the effect of functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

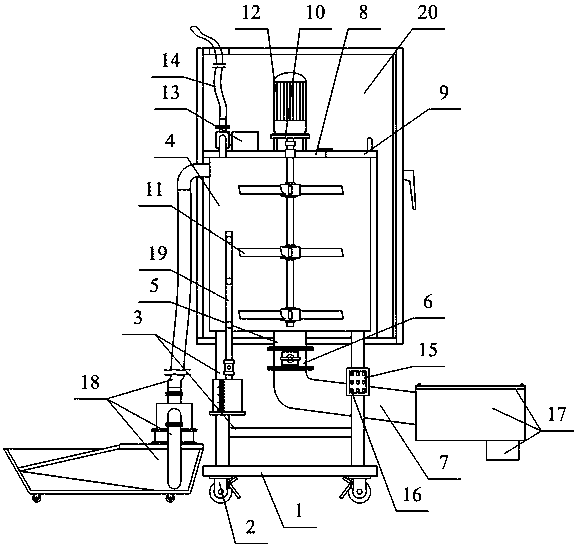

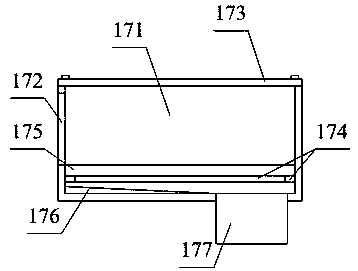

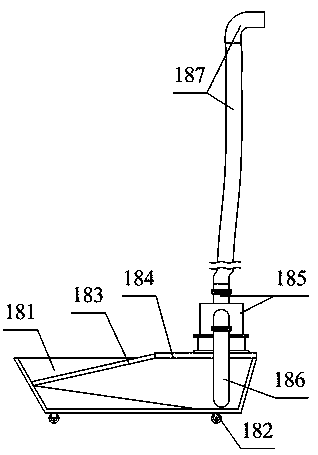

[0044] as attached figure 1 to attach figure 2 As shown, the intelligent large-scale cement foaming machine includes a base plate 1, a moving wheel 2, a support frame 3, a foam tank 4, a discharge head 5, a flap valve 6, a delivery pipe 7, a sealing plate 8, and a flipping plate 9 , frame 10, stirring frame 11, rotating motor 12, suction pump 13, connecting hose 14, PLC15, switch 16, auxiliary filter box structure 17, auxiliary delivery box structure 18, sampling observation tube frame structure 19 and noise reduction protection The cover structure 20, the moving wheels 2 are respectively bolted around the lower surface of the base plate 1; the support frame 3 is welded around the upper surface of the base plate 1, and the upper end of the support frame 3 is welded with a foam tank 4; The discharge head 5 is welded to the middle part of the lower end of the foaming tank 4; the flap valve 6 is flange-connected to the lower end of the discharge head 5; the delivery pipe 7 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com