Coke tower decoking device for needle coke production process

A production process and coke tower technology, applied in coke ovens, furnace prevention/removal of fouling, petroleum industry, etc., can solve the problems of slow cooling speed of coking towers, inconvenient for materials to be exported downward, and inconvenient for the positioning of exporting racks, etc. , to achieve the effect of increasing the degree of cleanliness and increasing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

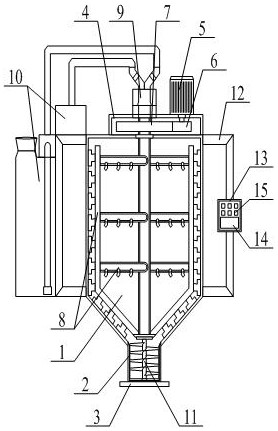

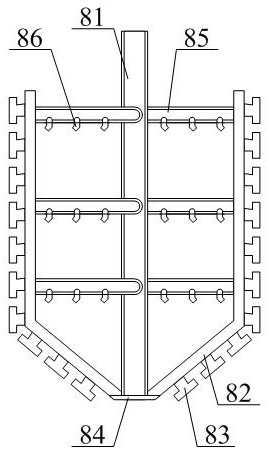

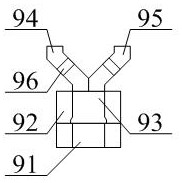

[0042] as attached figure 1 And attached Figure 4 shown

[0043] The present invention provides a coke tower decoking device used in the production process of needle coke, comprising a coking tower 1, an outlet pipe 2, an outlet flange 3, a mounting cover 4, a driving motor 5, a driving gear 6, a driven gear 7 and Scrape off the injection rack structure 8, the outlet pipe 2 is welded on the lower part of the coking tower 1; the outlet flange 3 is welded on the lower part of the outlet pipe 2; the installation cover 4 bolts are installed on the upper part of the coking tower 1 ; The drive motor 5 bolts are installed on the upper right side of the installation cover 4; the driving gear 6 is arranged on the inside of the installation cover 4, and the key is connected to the output shaft of the drive motor 5; The structure 8 is installed inside the coking tower 1; the upper part of the installation cover 4 is also provided with a confluence positioning frame structure 9; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com