Patents

Literature

35results about How to "Impact emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

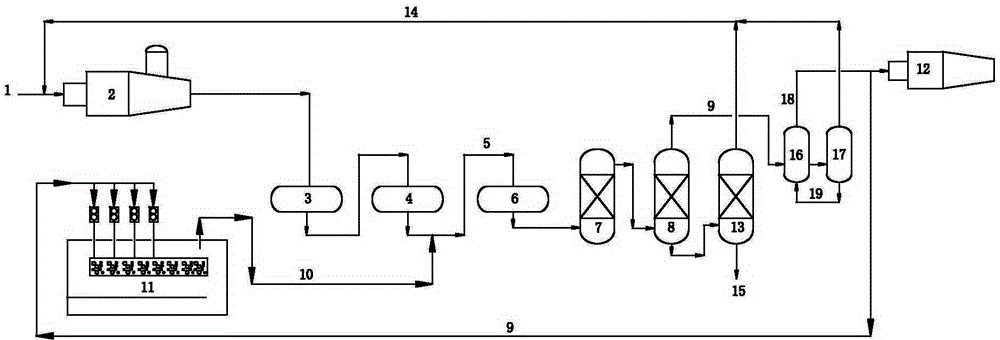

Sulfur recovery process for reducing SO2 emission

ActiveCN104555940APromote absorptionWith savingsDispersed particle separationSulfur preparation/purificationFlue gasSulfur

The invention belongs to the technical field of sulfur recovery, and particularly relates to a sulfur recovery process for reducing SO2 emission. According to the sulfur recovery process, a thermal reaction unit, a catalytic reaction unit and a tail gas purification unit are utilized; based on the traditional Claus and SCOT tail gas treatment process, an ammonia water absorption tank is additionally arranged for removing H2S from purified tail gas, so as to ensure that the H2S content in the purified tail gas is lower than 5 mg / m<3>; waste ammonia water is sent to a sewage stripping unit for treating; through the adoption of the sewage stripping device, H2S and ammonia can be respectively extracted; the extracted H2S is returned to a sulfur recovery device for sulfur recovery, and the extracted ammonia is returned to the ammonia water absorption tank for cyclic utilization; finally, the flue-gas SO2 emission concentration for the sulfur recovery device can be reduced below 100 mg / m<3>, the new environmental protection standard to be executed is satisfied, and a novel method for building a new sulfur recovery device with a small investment and low operating cost is provided. The sulfur recovery process is excellent in absorption effect, simple to operate, low in expense, environment-friendly, and economical.

Owner:CHINA PETROLEUM & CHEM CORP

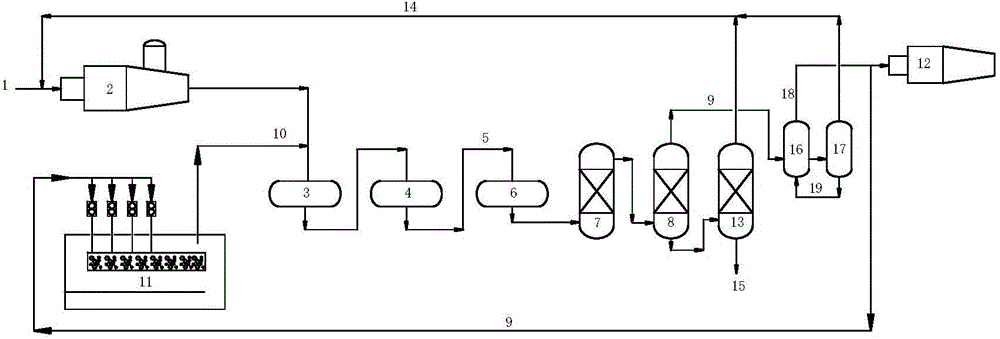

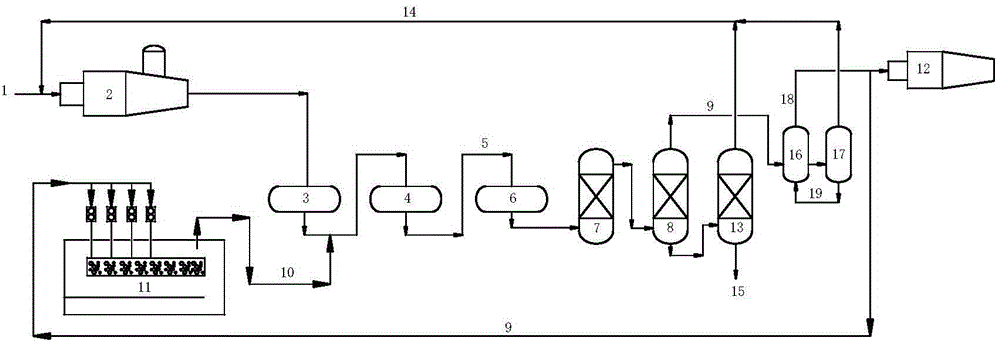

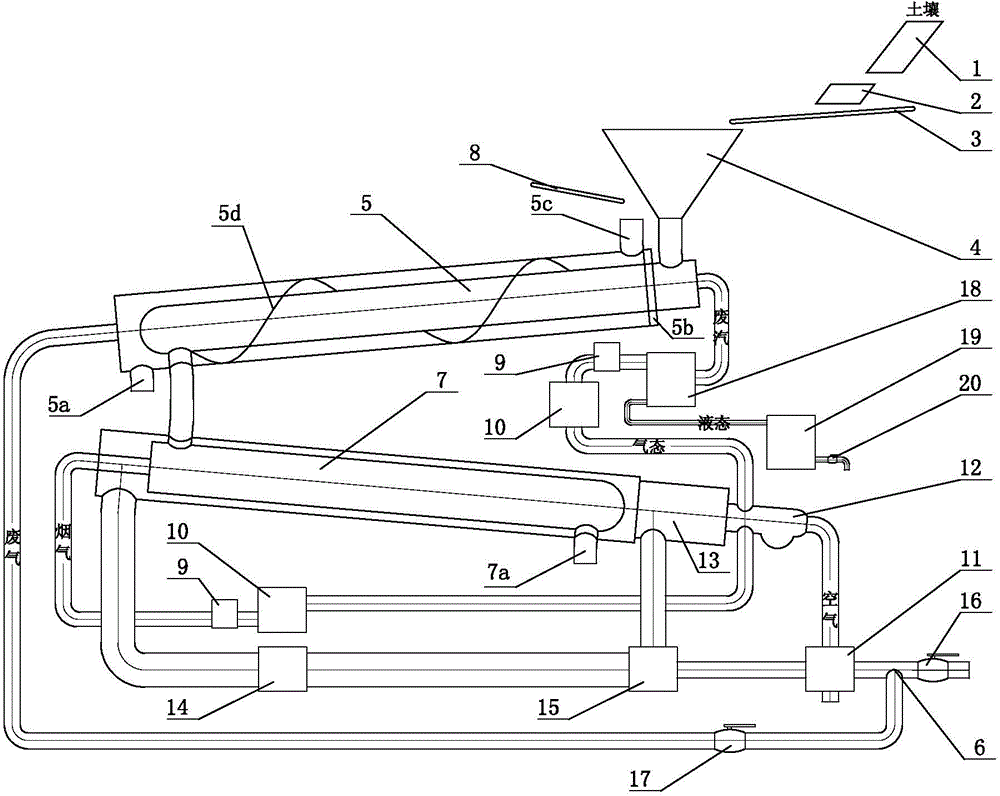

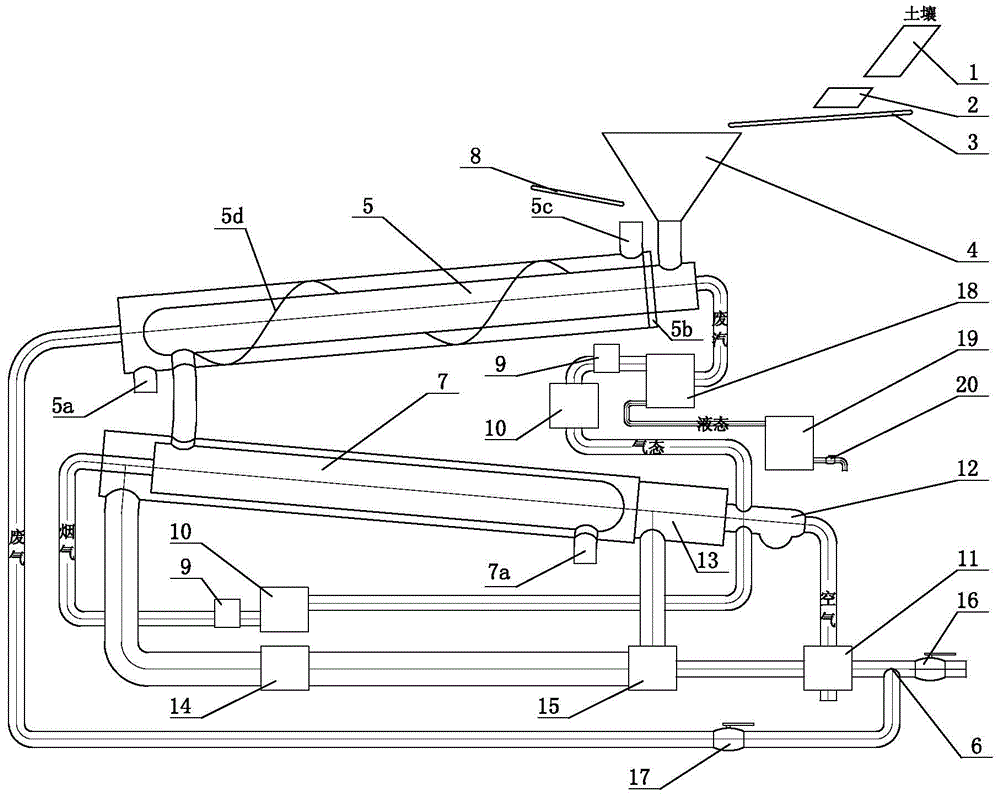

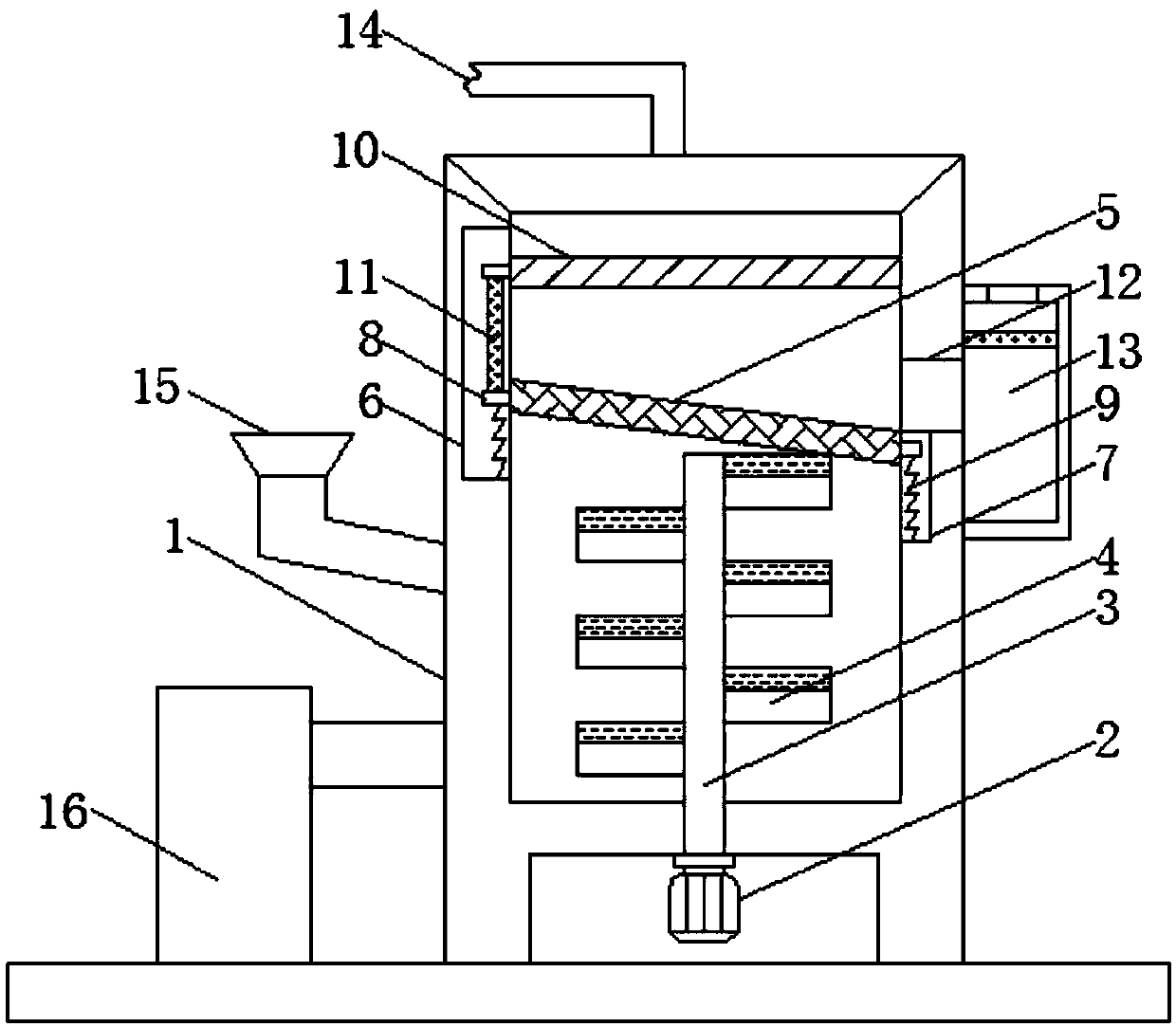

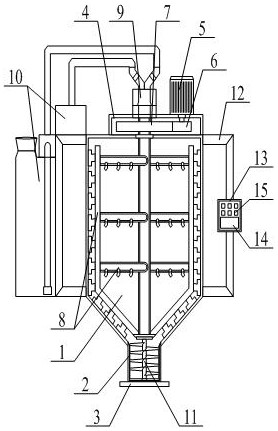

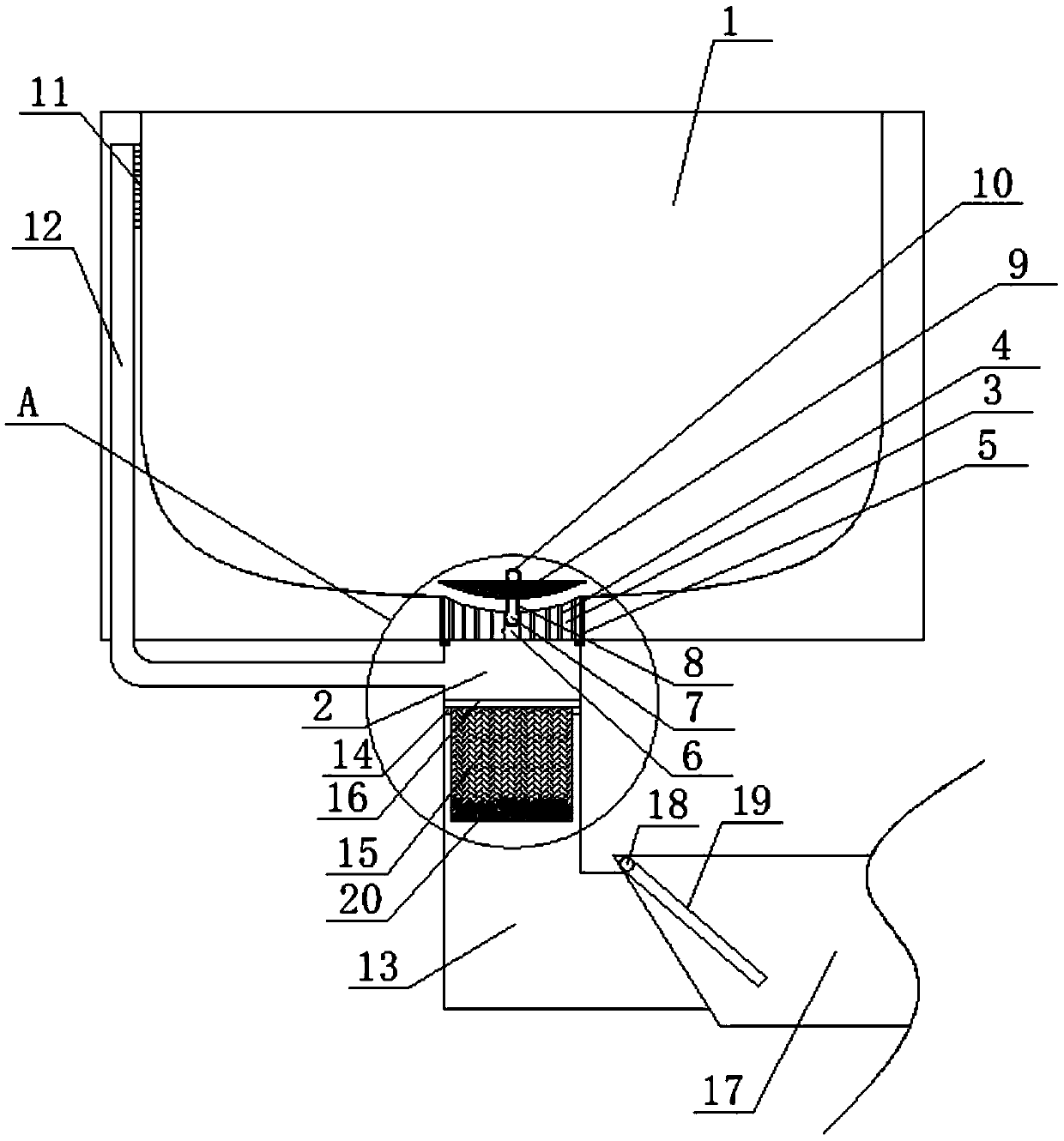

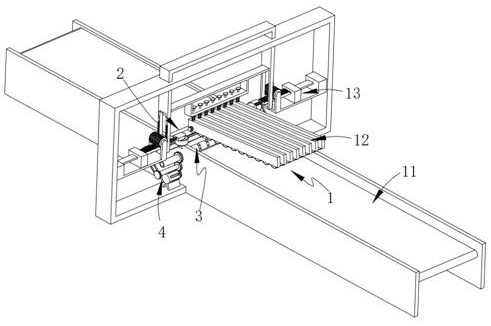

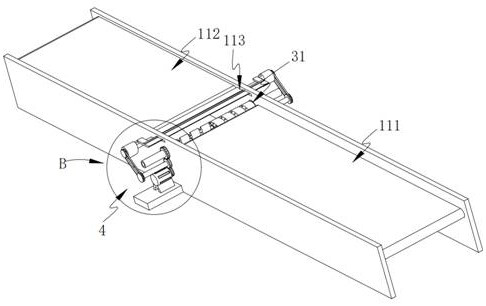

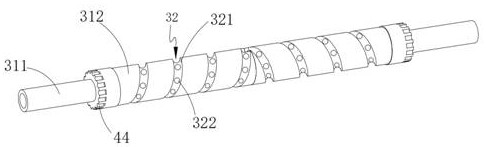

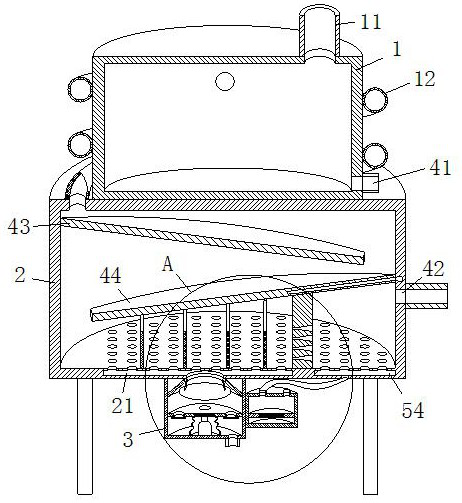

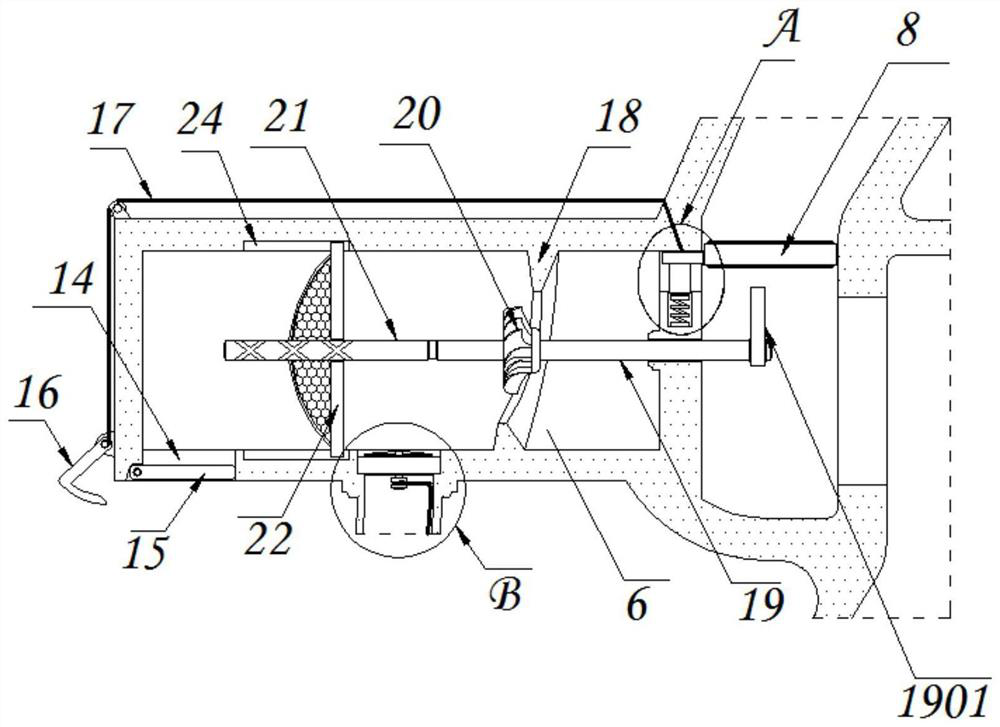

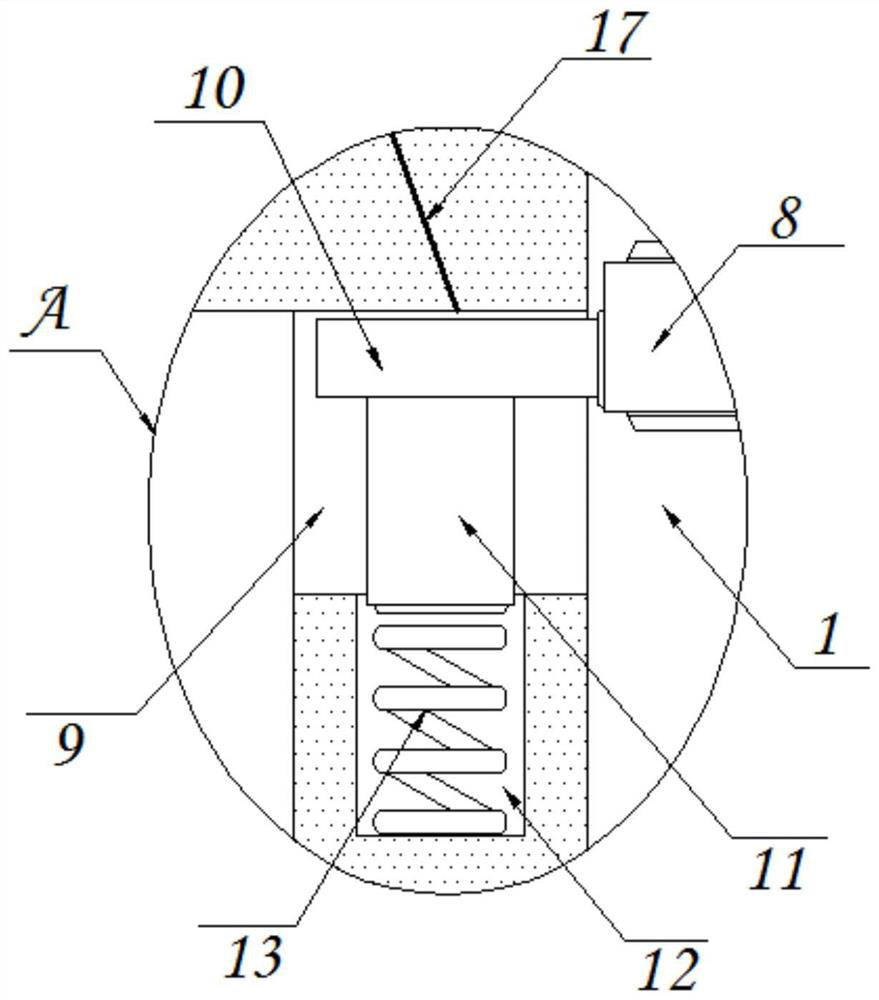

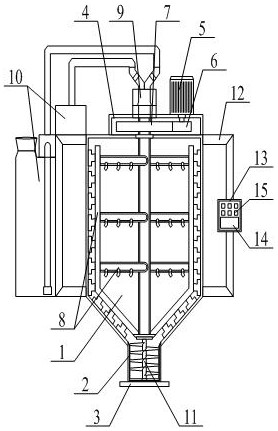

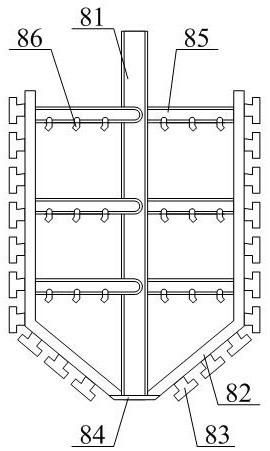

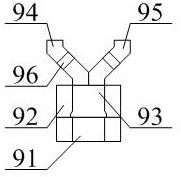

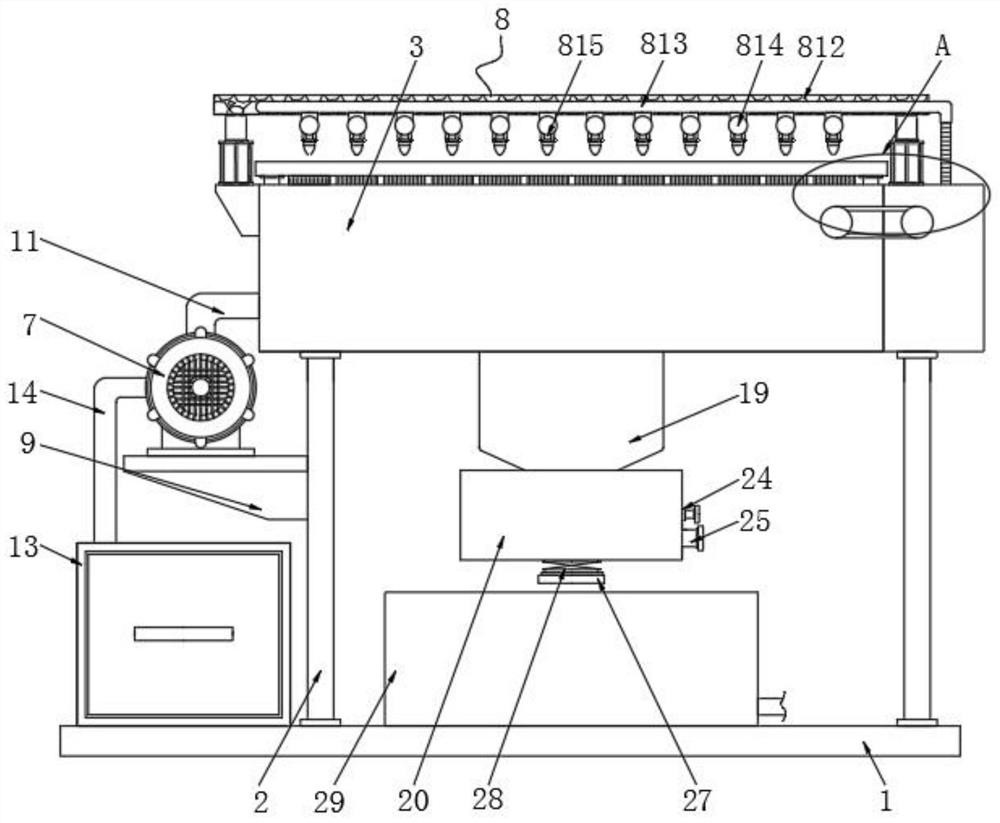

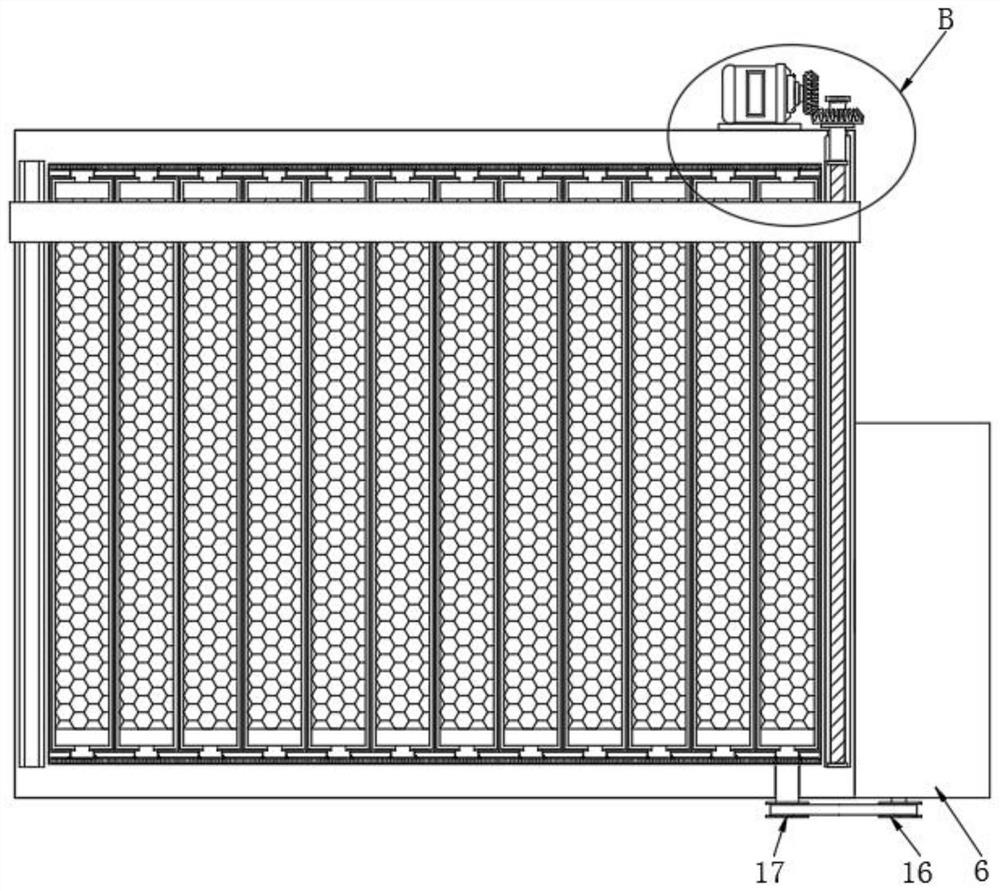

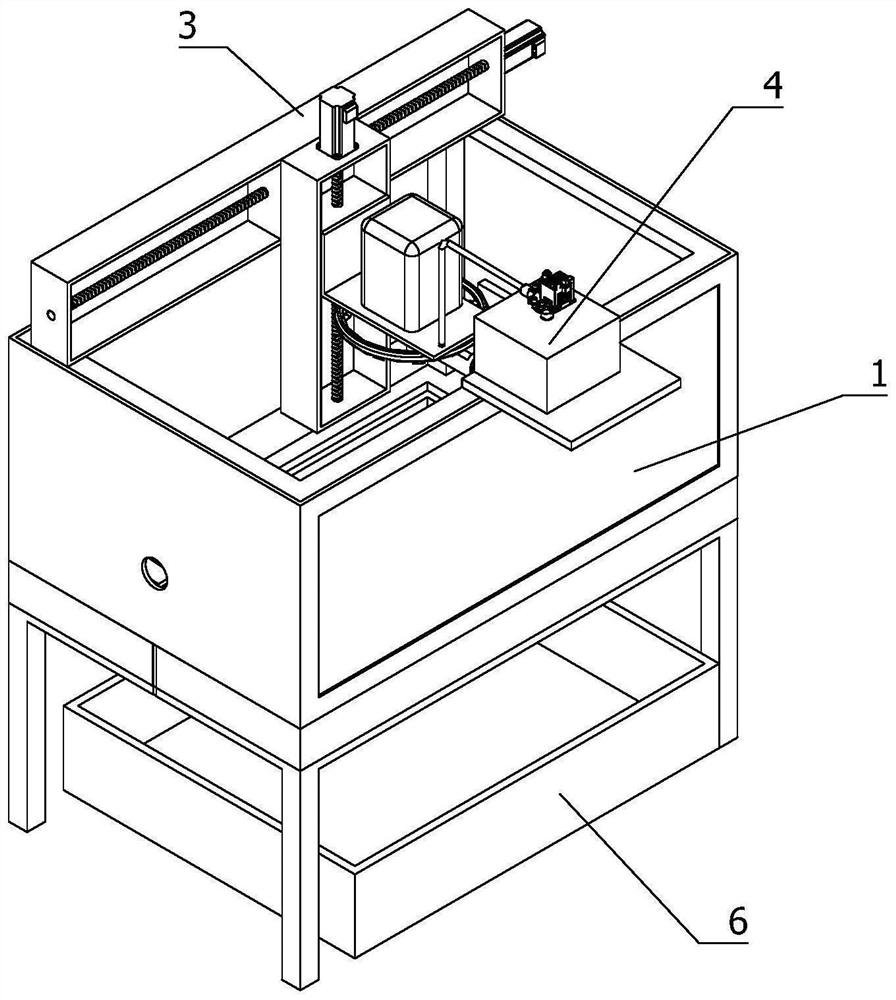

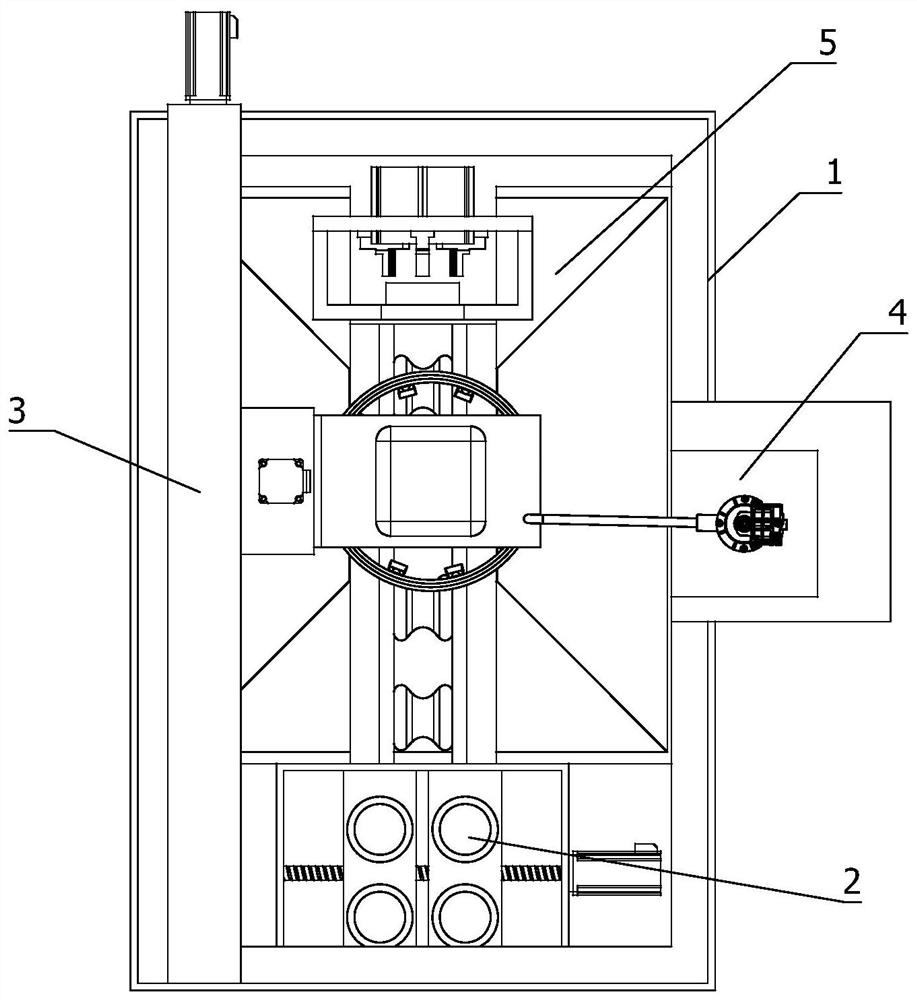

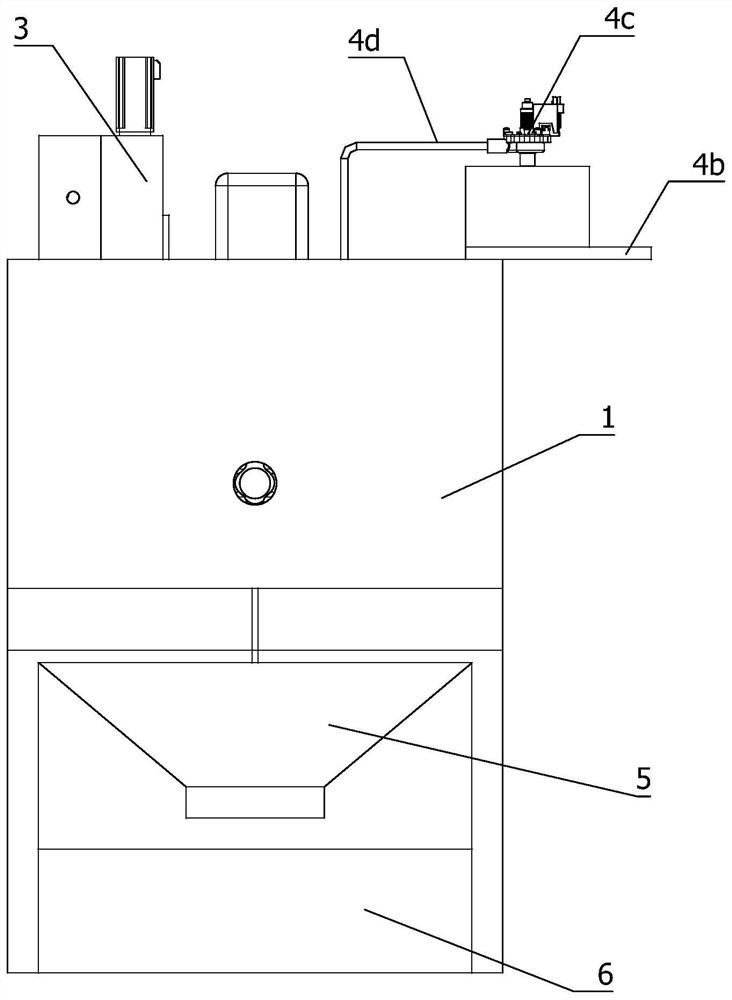

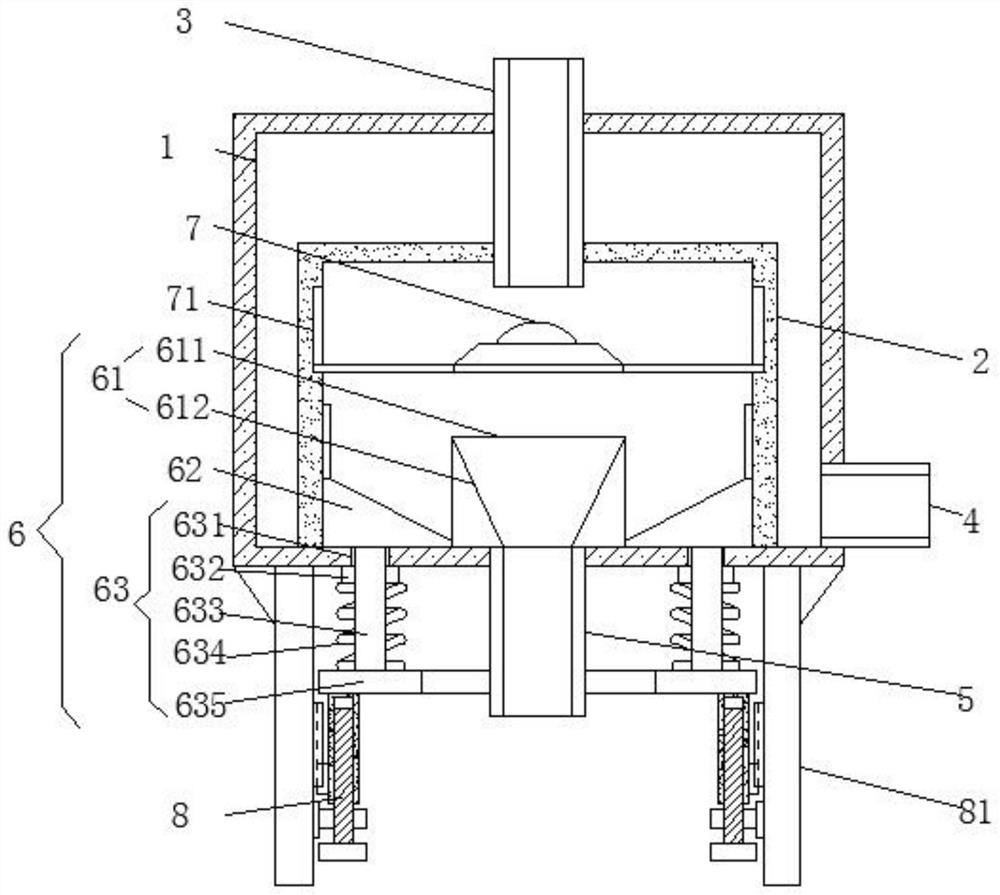

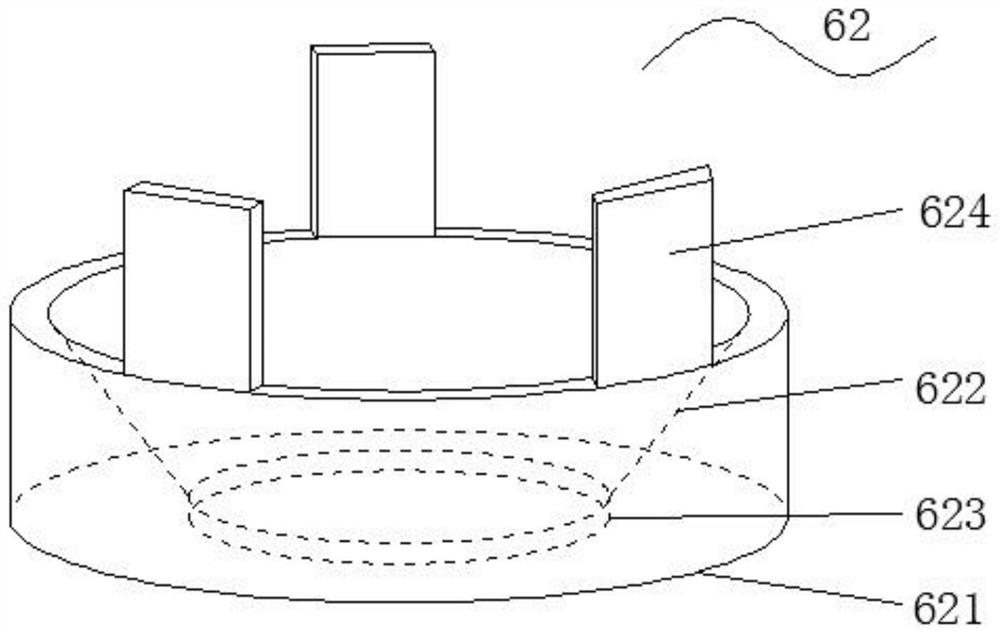

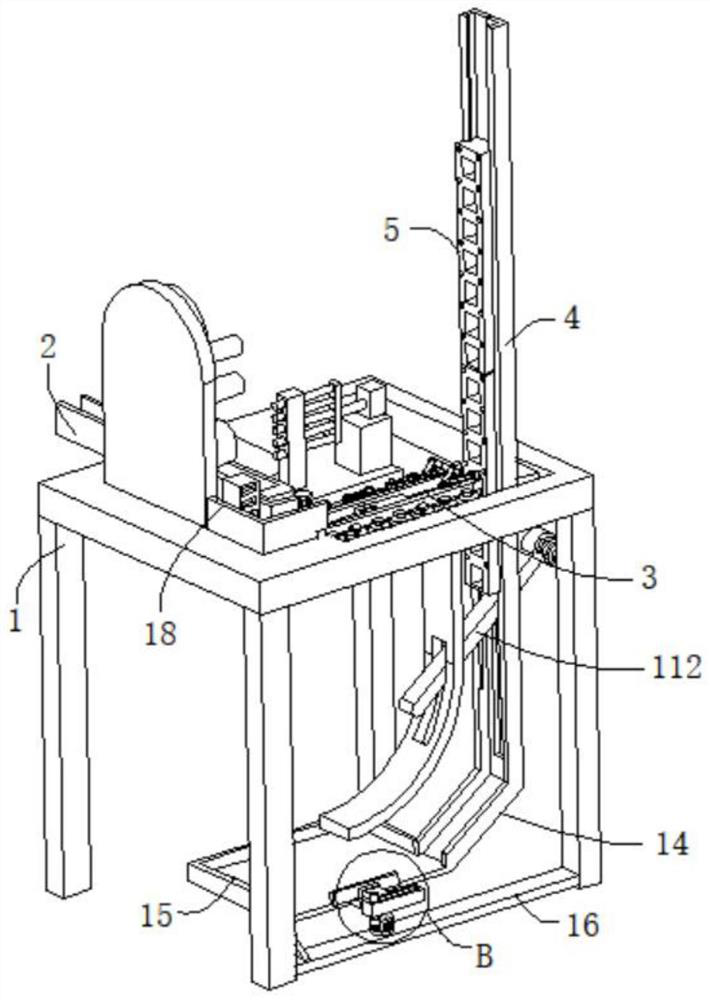

Contaminated soil remediation system

ActiveCN104785512AImpact emissionsNo pollution problemContaminated soil reclamationCombustion chamberCombustor

The invention discloses a contaminated soil remediation system. Soil is sequentially fed into the inner container of a waste heat rotary kiln through a feeding cabin, the inner container of a heat desorption rotary kiln, and the interlayer of the waste heat rotary kiln through a first conveyer belt, and is finally discharged out through a first soil outlet; air is fed into a combustion chamber for combustion through a combustor; generated fume is fed into the interlayer of the heat desorption rotary kiln to make straight line movement, is further accessed to the interlayer of the waste heat rotary kiln through a pipeline to make spiral movement, and is finally discharged out through a fume outlet formed in the shell of the waste heat rotary kiln; the waste gas generated in the inner container of the heat desorption rotary kiln is accessed to the combustor for incineration; the waste gas generated in the inner container of the waste heat rotary kiln is accessed to a condensation separator through a pipeline; the gas separated in the condensation separator is accessed to the combustion for incineration through another pipeline; a liquid separated in the condensation separator is discharged out through another pipeline. The contaminated soil remediation system has the characteristics of low energy consumption, high efficiency, low manufacturing cost, high easiness to implement, good remediation effect and the like, and has wide market prospect.

Owner:重庆化医太湖锅炉股份有限公司 +1

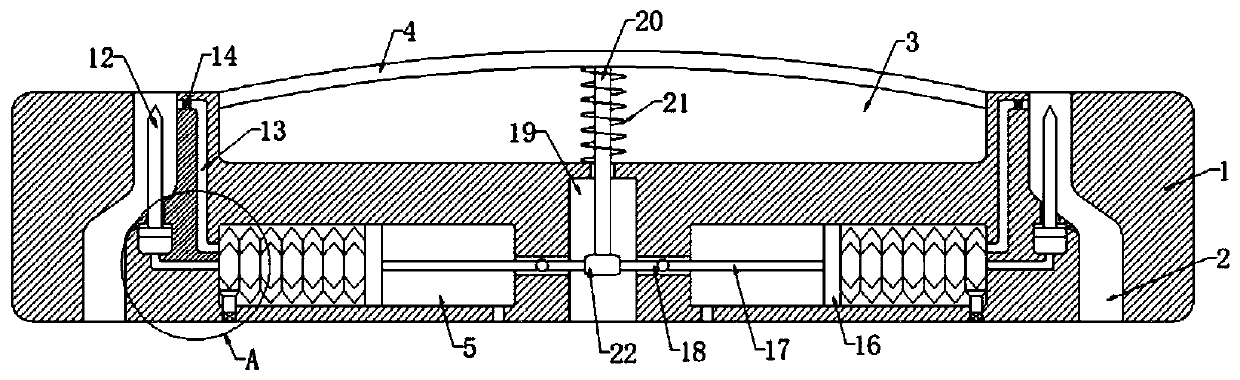

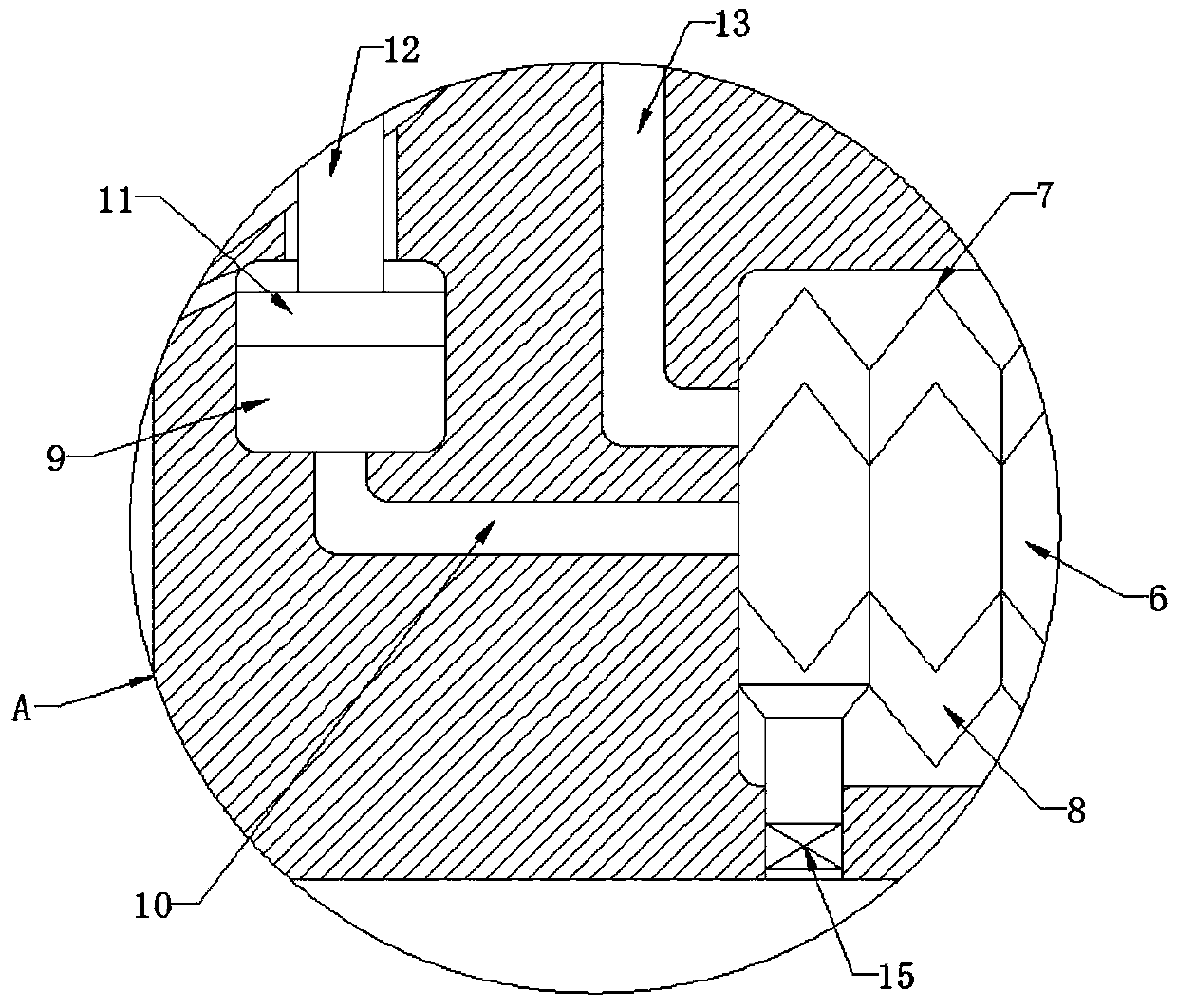

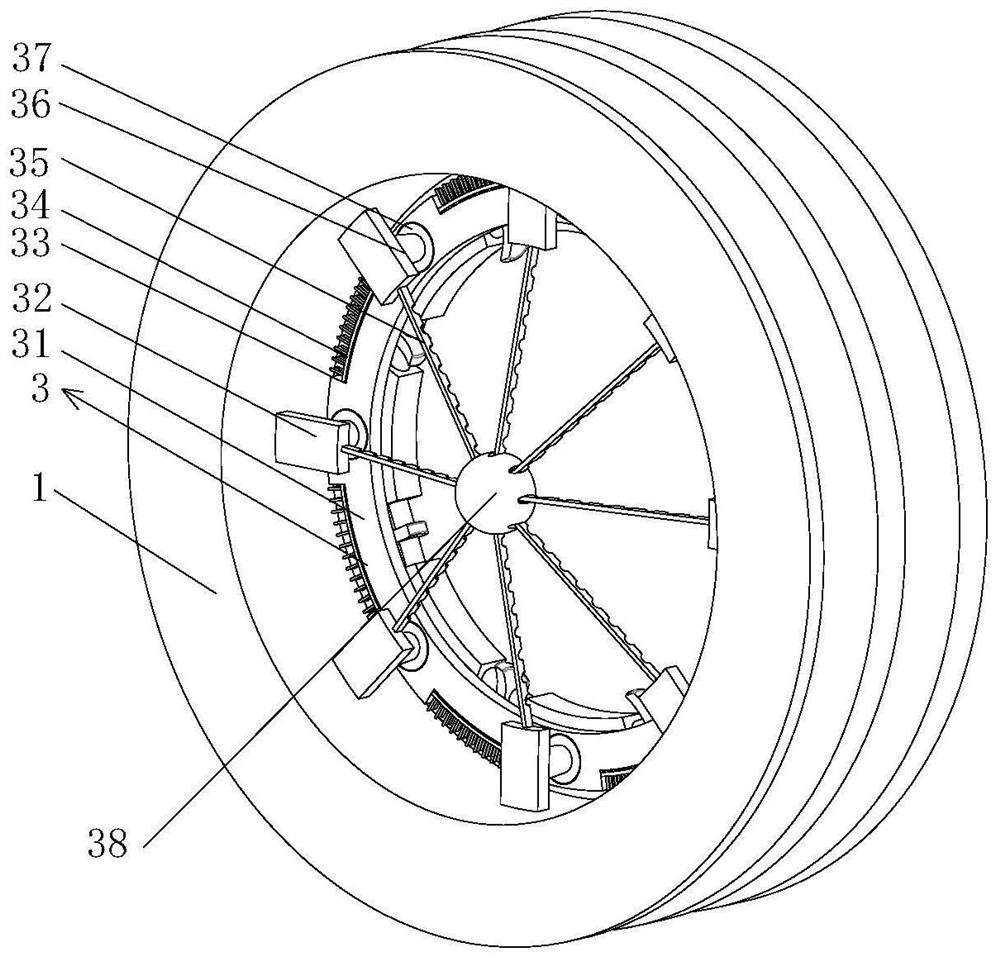

Anti-blocking water absorption manhole cover

ActiveCN111305363AAffect drainage efficiencyPrevent splashSewerage structuresClimate change adaptationMarine engineeringAirbag

The invention discloses an anti-blocking water absorption manhole cover which comprises a manhole cover body. Multiple water inlets are formed at the upper end of the manhole cover body in the circumferential direction of the manhole cover body at equal distance. Cavities are symmetrically formed in the manhole cover body. A first telescopic airbag is fixedly connected to the inner wall of each cavity, and a second telescopic airbag is arranged on the outer side of each first telescopic airbag in a sleeving manner. A dredging device used for dredging the water inlets is mounted on the manholecover body. According to the anti-blocking water absorption manhole cover, through the arrangement of an elastic plate, a vertical rod, first cross rods, second cross rods and sliding plugs, when a vehicle passes through the elastic plate, the vertical rod can drive the first cross rods to move through the second cross rods, the sliding pugs drive the first telescopic airbags and the second d telescopic airbags to be stretched, so that ejector rods move downwards, and the process that rainwater enters the water inlets is accelerated; and the situation that when the vehicle fast runs on the manhole cover body, rainwater on the manhole cover body is drained away, and the water drainage efficiency of the manhole cover body is influenced is avoided.

Owner:台州友驿科技有限公司

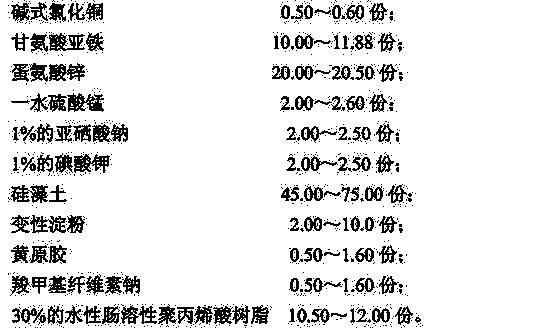

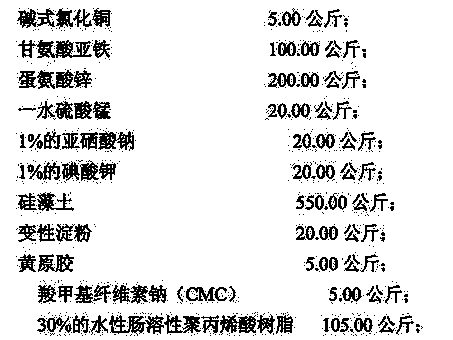

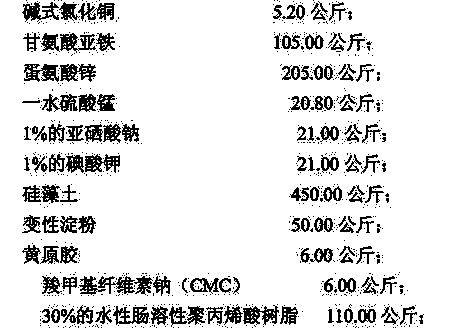

Granulated and enteric coated composite trace elements and preparation method thereof

InactiveCN104161189APromote fastLow manufacturing costAnimal feeding stuffAccessory food factorsNutrientSodium carboxymethylcellulose

The invention discloses granulated and enteric coated composite trace elements and a preparation method thereof. The composite trace elements are formed by granulating and enteric coating of raw materials, and the raw materials comprise the following components in parts by weight: copper oxychloride 0.5-0.6, ferrous bisglycinate 10-11.88, zinc methionine 20-20.50, manganese sulfate monohydrate 2-2.6, 1% sodium selenite 2-2.5, 1% potassium iodate 2-2.5, diatomite 45-75, modified starch 2-10, Xanthan gum 0.5-1.6, sodium carboxymethyl cellulose 0.5-1.6, and 30% water-based enteric polyacrylic resin 10.50-12. The preparation method comprises the following steps: humidifying and mixing of the above raw materials; swinging, extruding and granulating; vortex particle shaping; enteric coating; drying and screening. The specific surface area of the trace elements is obviously reduced, the trace elements are effectively isolated from nutrients which are easily induced and oxidized in the feed, vitamins in premix and fat in concentrated feed are thoroughly prevented from being induced and oxidized by the trace elements, and the palatability of the feed products is increased. Moreover, the granulation speed is fast, the granules are uniform, and the cost of the trace elements is low.

Owner:SHANGHAI XINNONG FEED

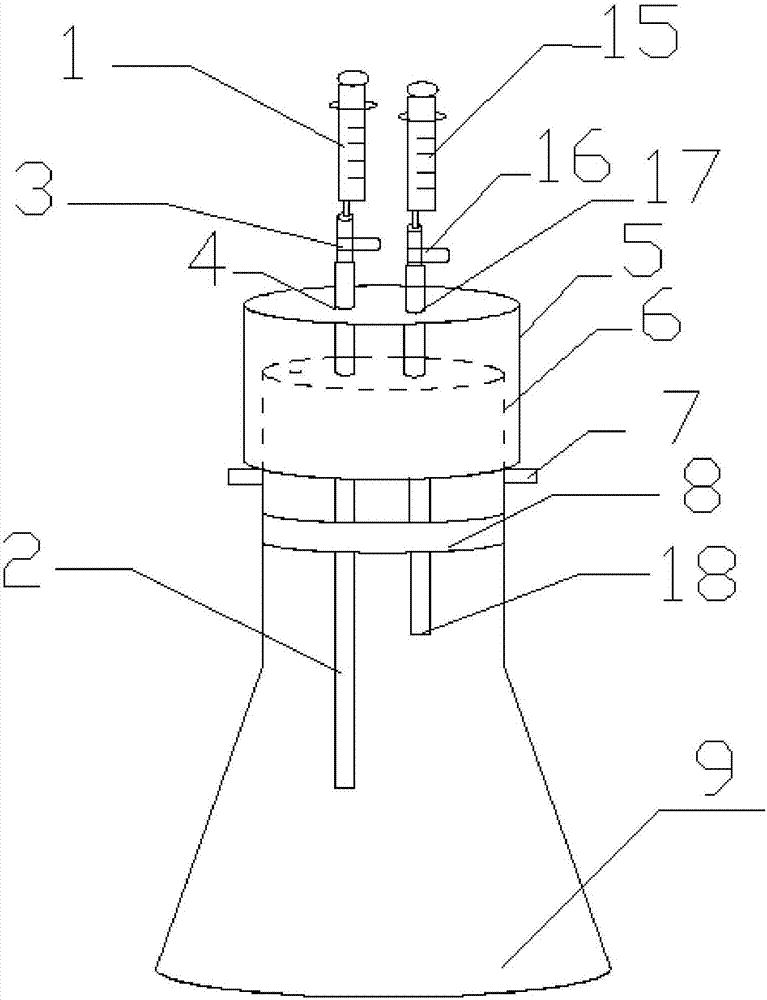

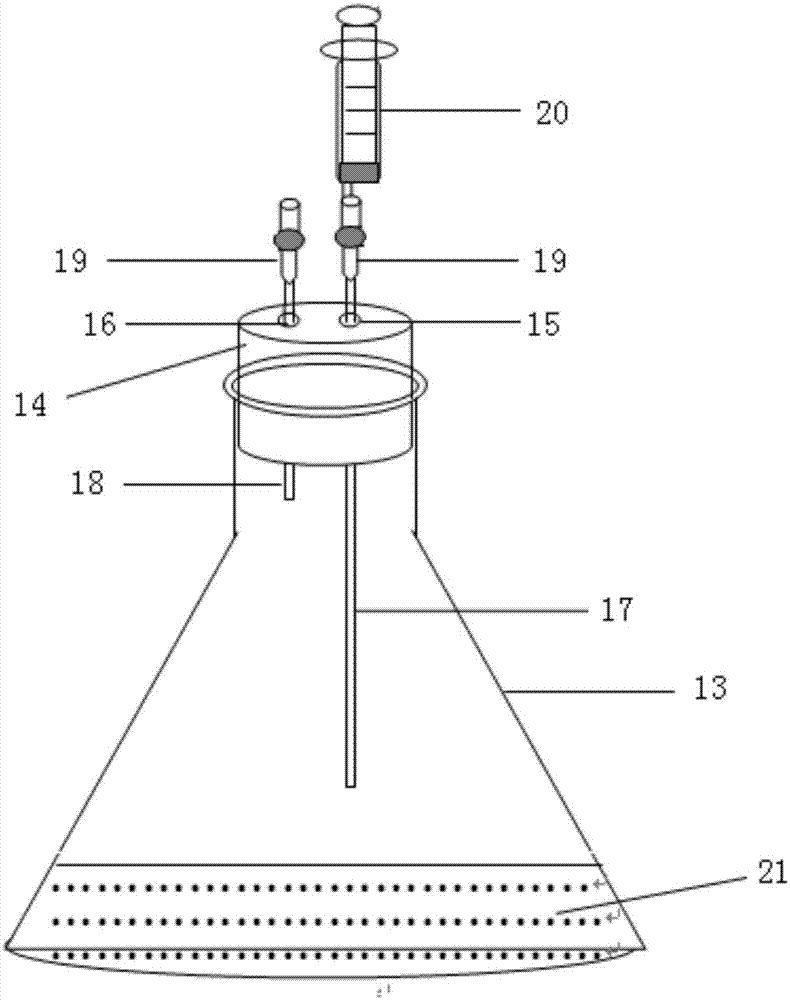

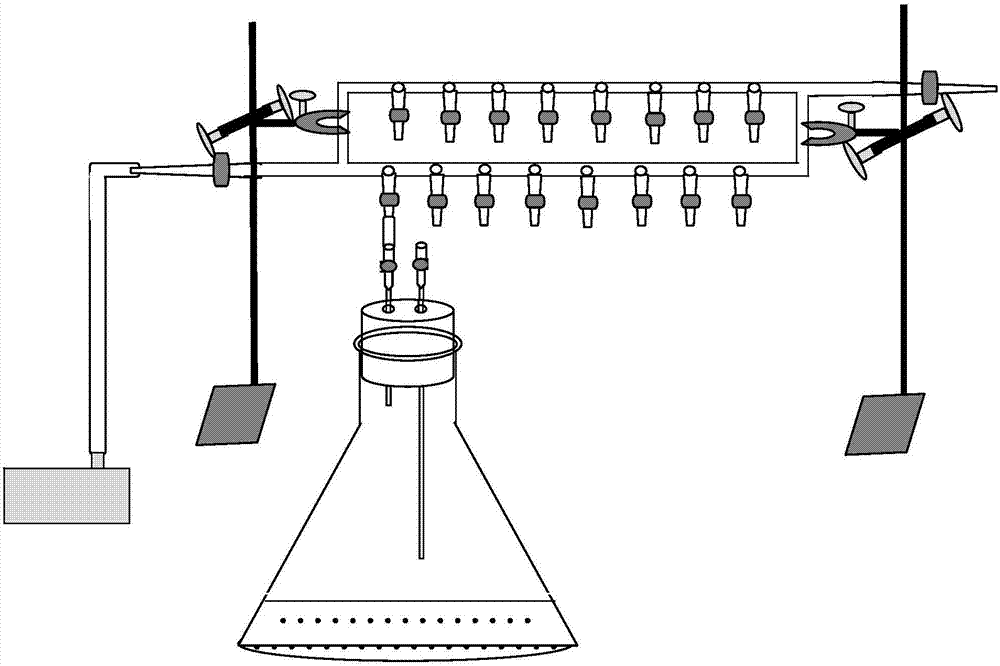

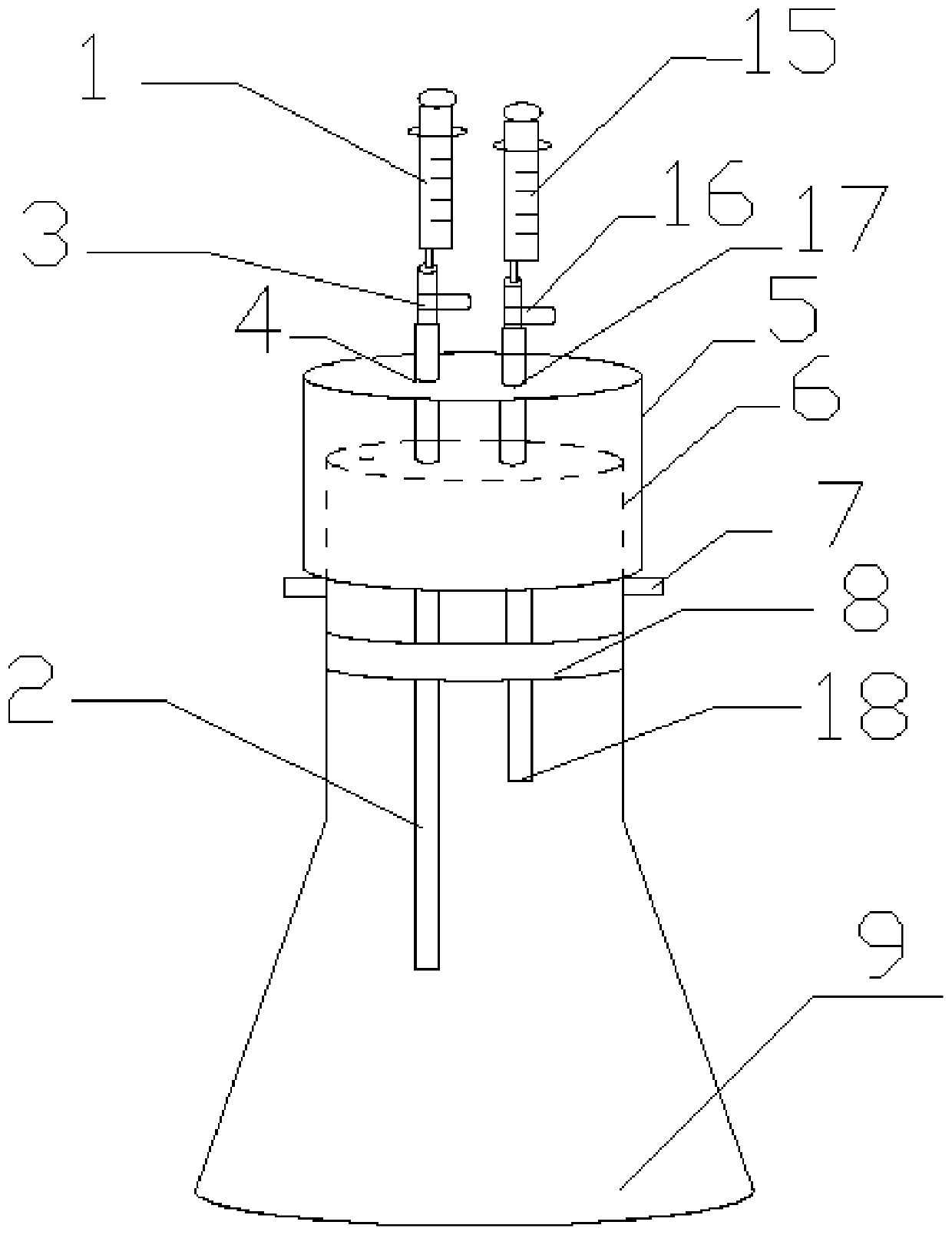

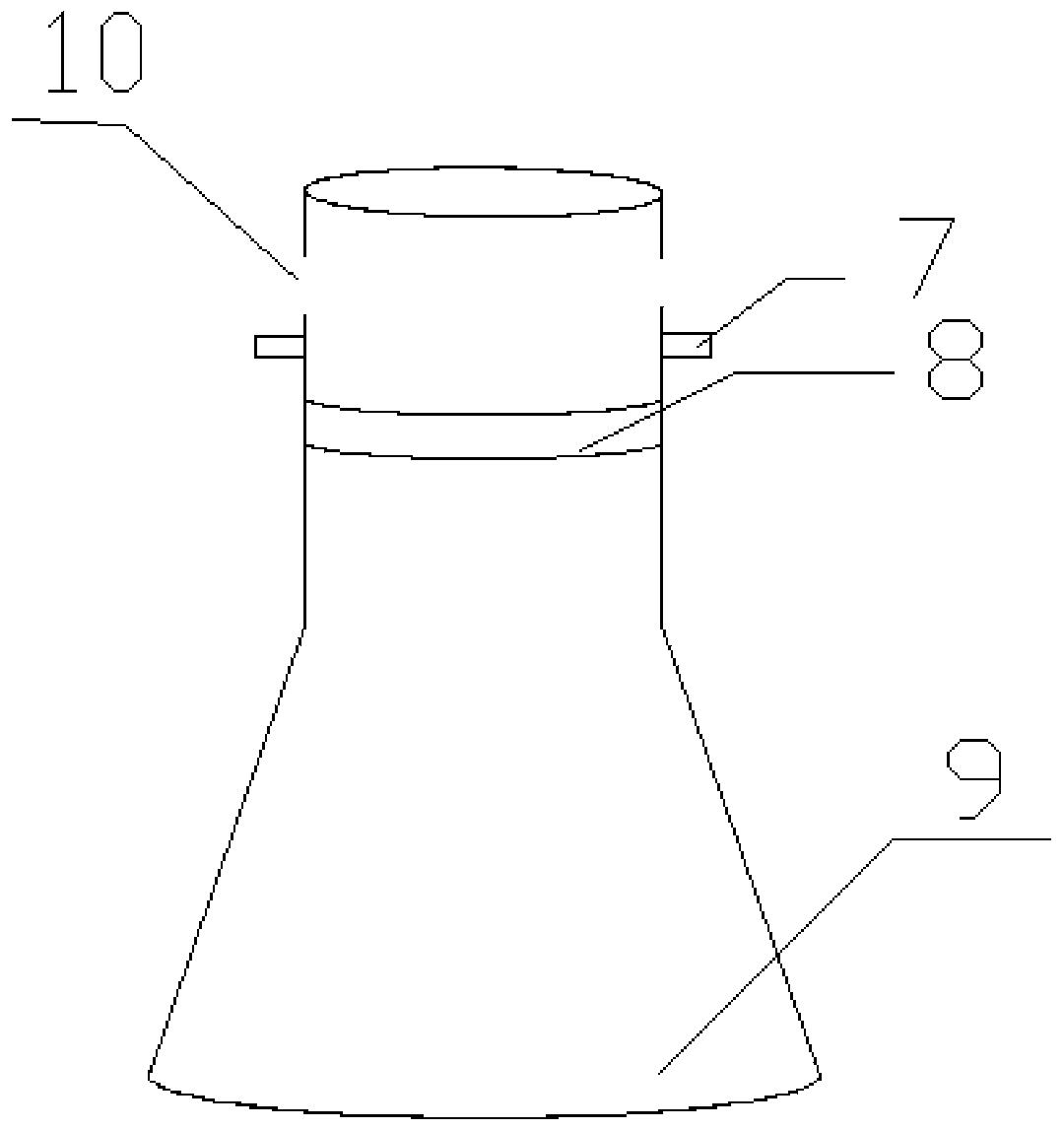

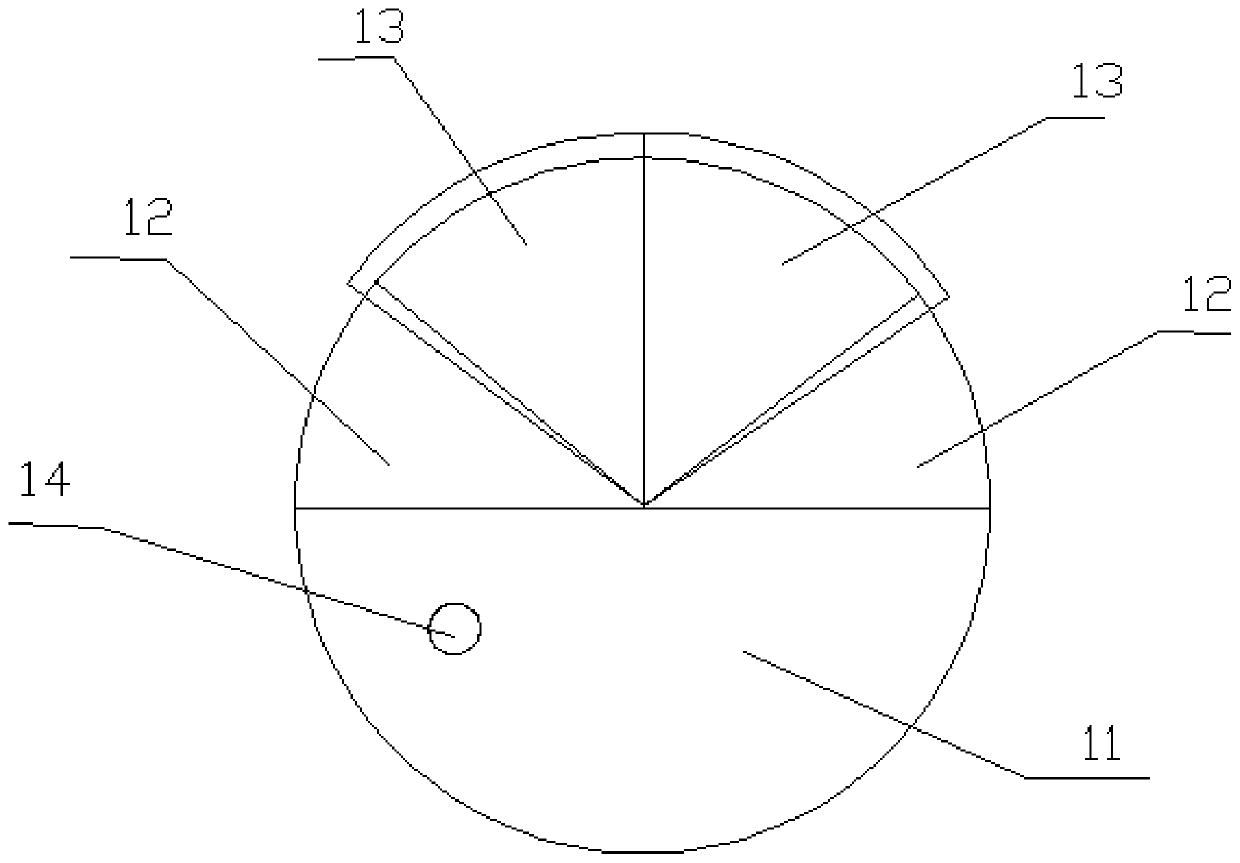

Aerobic culture and gas collection integrated indoor soil culture apparatus, and application thereof

ActiveCN106940365ASimple structureEasy to manufactureWithdrawing sample devicesPreparing sample for investigationGas collecting tubeEngineering

The invention relates to an aerobic culture and gas collection integrated indoor soil culture apparatus, and an application thereof. The apparatus comprises a culture container, the top mouth of the culture container is provided with a separator plate matched with the top mouth, the separator plate comprises a separator plate body and a gas opening and closing device, the separator plate is in closed fixed connection with an aeration container with an open top end, the sidewall of the aeration container is provided with an aeration opening, the ventilation container is covered with a top cover, the top cover is provided with a gas inlet hole and a gas collecting hole, a gas inlet tube is fixed in the gas inlet hole, one end of the gas inlet tube is inserted into the culture container, the other end of the gas inlet tube is connected with a balancing tube, a gas collecting tube is fixed in the gas collecting hole, one end of the gas collecting tube is inserted into the culture container, and the other end of the gas collecting tube is connected with a gas collecting needle. The apparatus has the advantages of implementation of aerobic culture and gas collection on the apparatus, small size, use in a limited space, convenience in operation, realization of closed culture under normal pressure, quantification of the initial culture concentration of a target gas, solving of the problem of target gas absorption due to the negative pressure caused by sampling, and real and effective reality-approaching culture and detection result.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Method for testing greenhouse gas emission of indoor culture soil

ActiveCN106932241ASimple structureEasy to manufactureWithdrawing sample devicesPreparing sample for investigationEngineeringGas exchange

The invention relates to a method for testing greenhouse gas emission of indoor culture soil. The method is implemented by using a gas exchange and culture gas production integral device; the gas exchange culture gas production integral device comprises a gas exchange device and a culture gas production device which is connected with the gas exchange device; the testing method comprises steps of opened culture of soil, gas exchange, sealed culture and gas collection. By adopting the method, the influence of gases generated from the soil at an early stage upon sealed culture gas emission is eliminated, sealed culture at normal pressure is achieved, meanwhile the problem that a target gas is absorbed by negative pressure in sampling is overcome, in addition, culture and gas collection of multiple culture flasks can be completed at one time, the initiation culture concentration is accordant, and the working efficiency is high.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Contaminated Soil Remediation System

ActiveCN104785512BImpact emissionsNo pollution problemContaminated soil reclamationCombustion chamberCombustor

Owner:重庆化医太湖锅炉股份有限公司 +1

Rotatable-drying textile assistant dryer

The invention discloses a rotatable-drying textile assistant dryer in the technical field of textile assistants. The rotatable-drying textile assistant dryer comprises a tank, wherein a motor is arranged on the outer wall of the bottom of the tank, the output end of the top of the motor extends into an inner cavity of the tank and is connected with a stirring rod, smashing devices are arranged onouter walls of the left side and the right side of the stirring rod, a first screen is arranged between inner walls of the left side and the right side of the tank, the outer wall of the bottom of a fixed block is connected with the outer wall of the top of a connecting block at the left side through a connecting rod, a discharge hole is formed in the outer wall of the right side of the tank and located between the first screen and a second screen, and an exhaust pipe is arranged at the top end of the tank. According to the dryer, the stirring rod drives the smashing devices to rotate to smasha larger textile assistant, drying of the textile assistant is facilitated, and besides, by means of baffles arranged at the tops of supporting blocks, the contact area between each smashing device and the textile assistant is increased, so that the smashing efficiency of the textile assistant is improved.

Owner:扬州市立达树脂有限公司

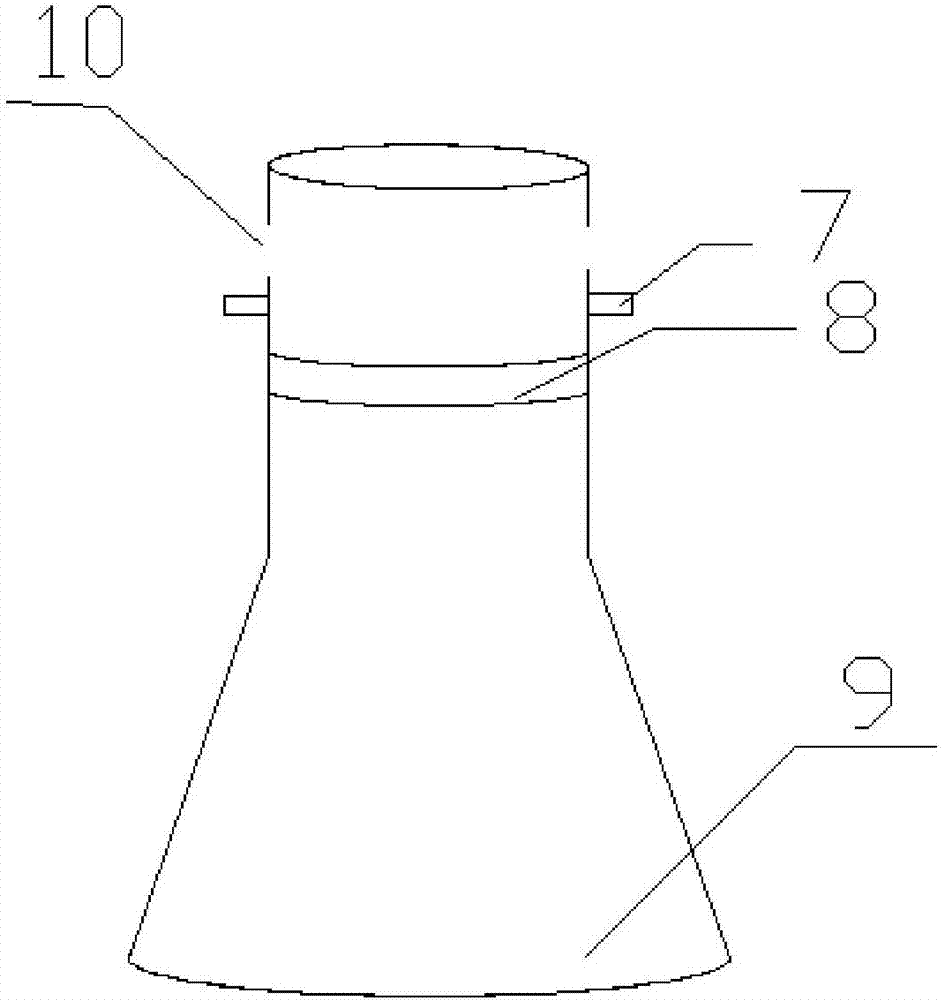

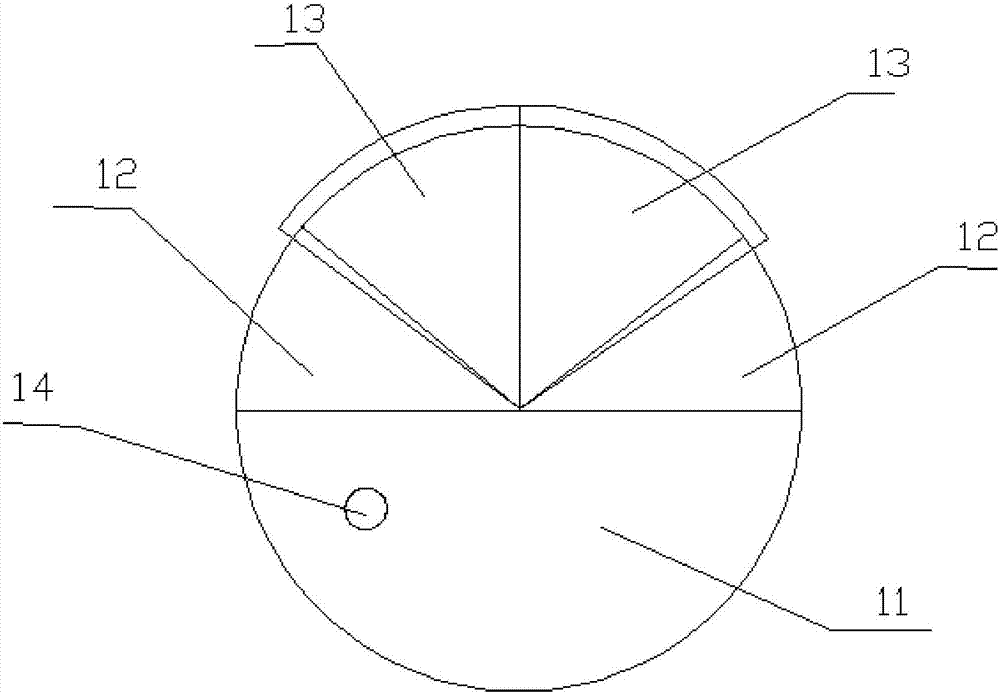

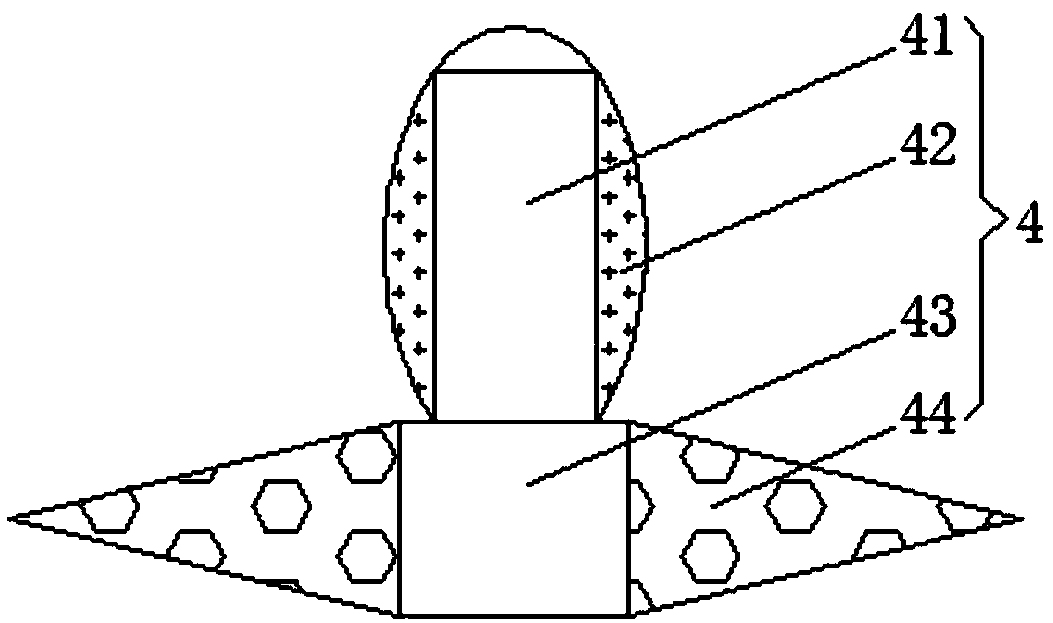

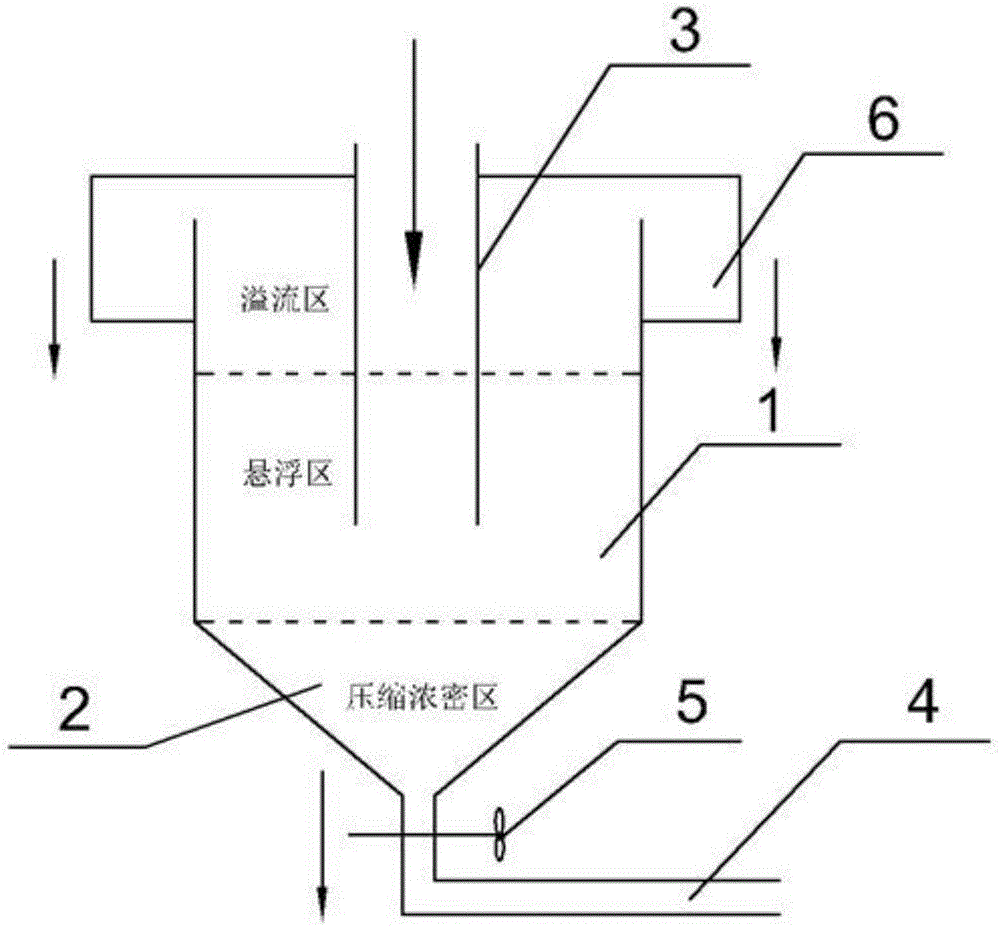

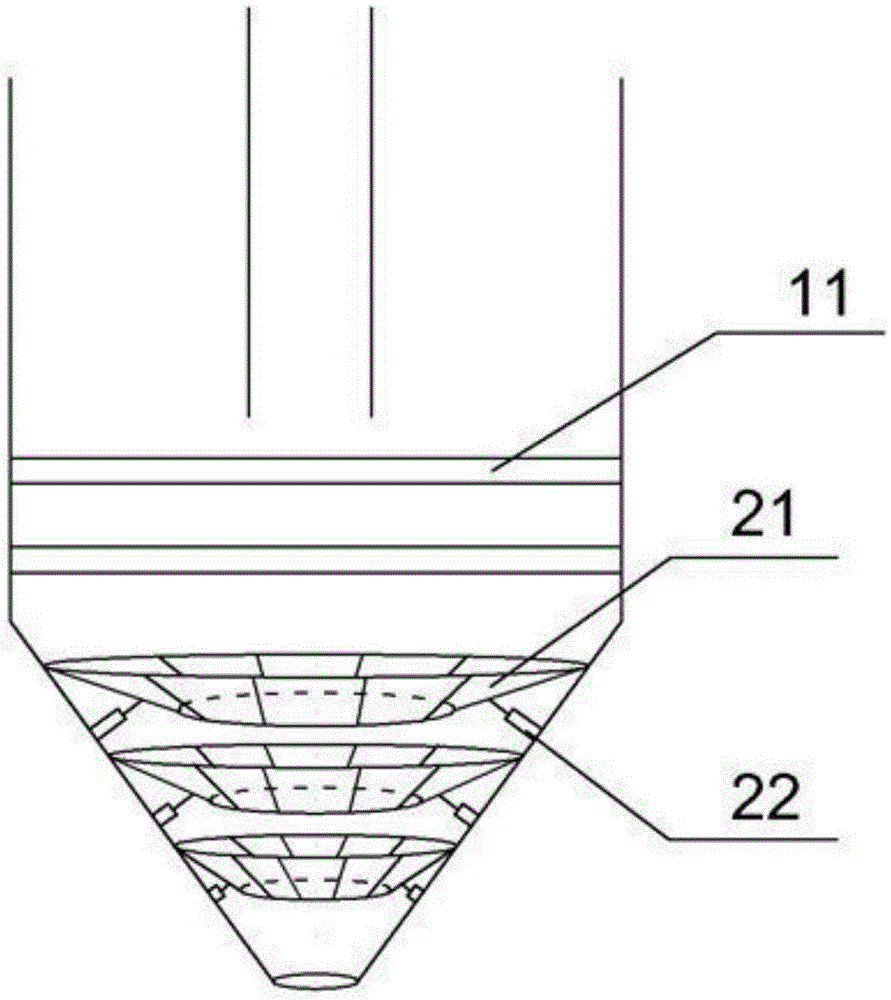

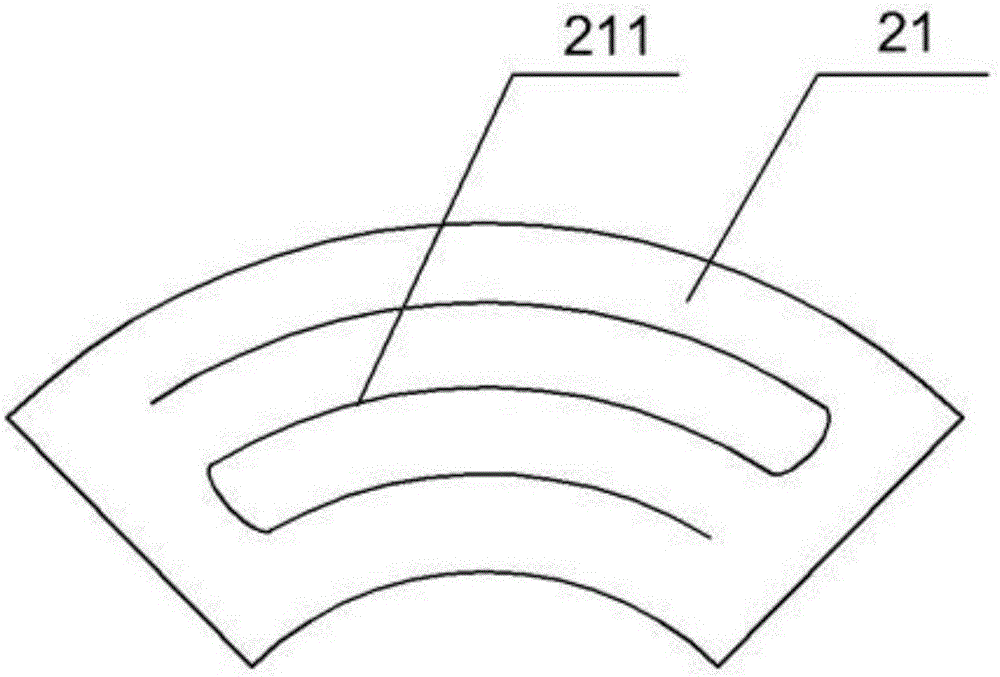

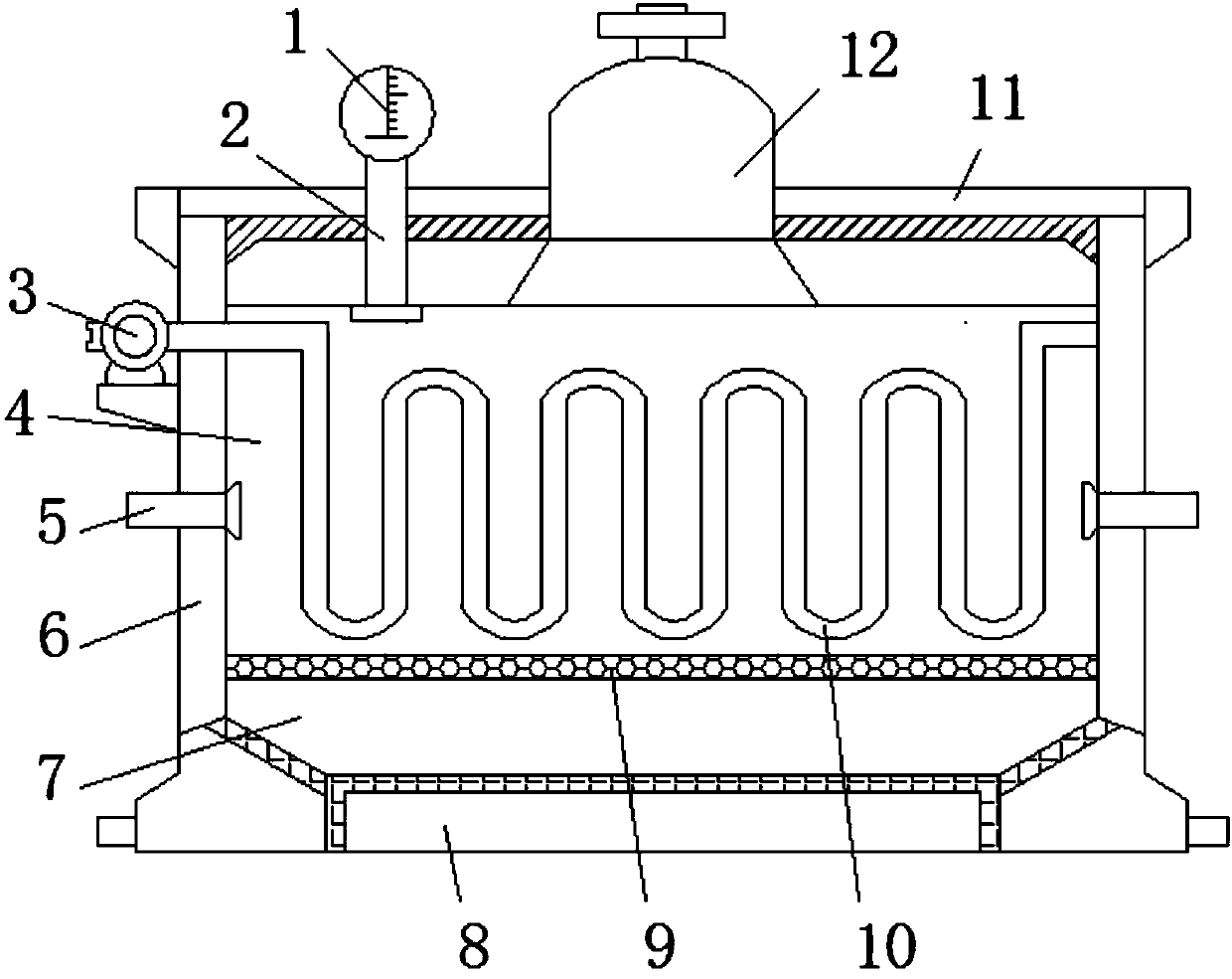

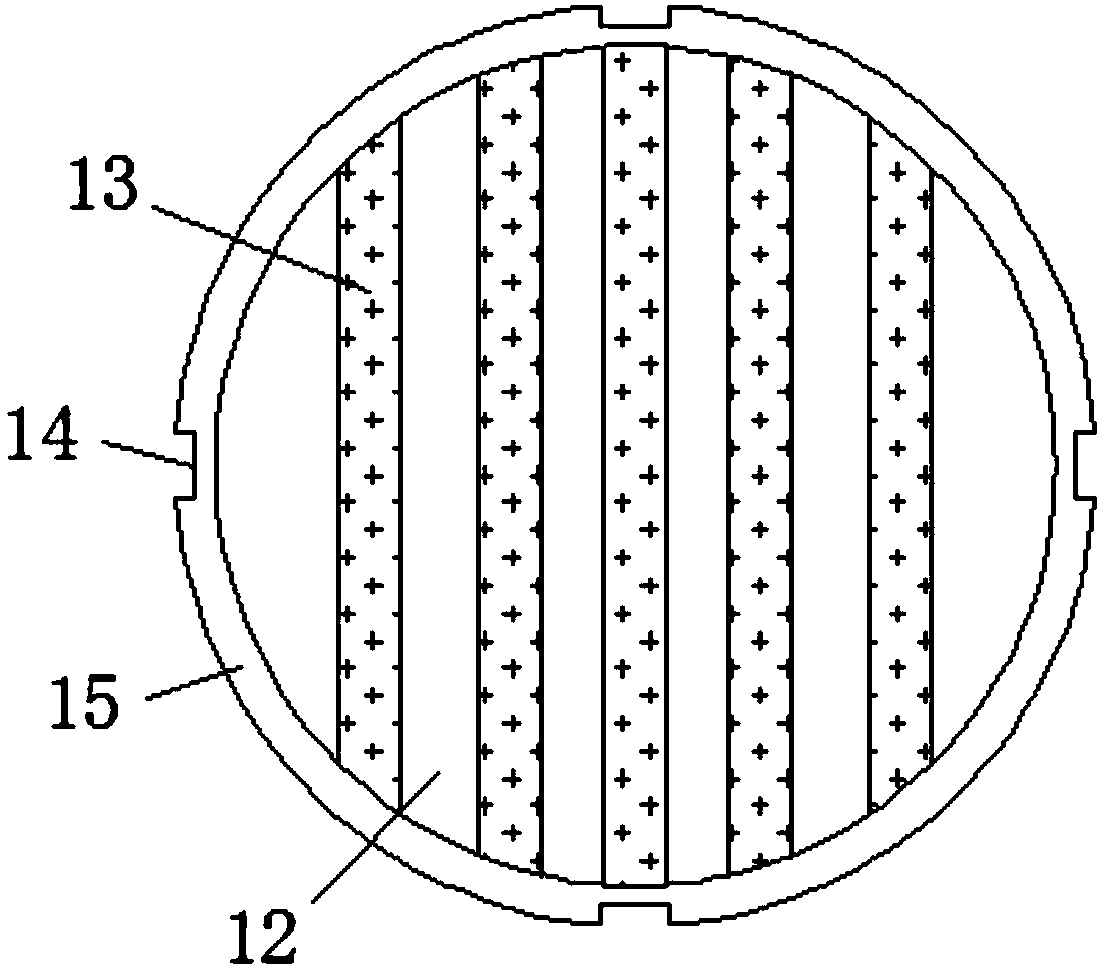

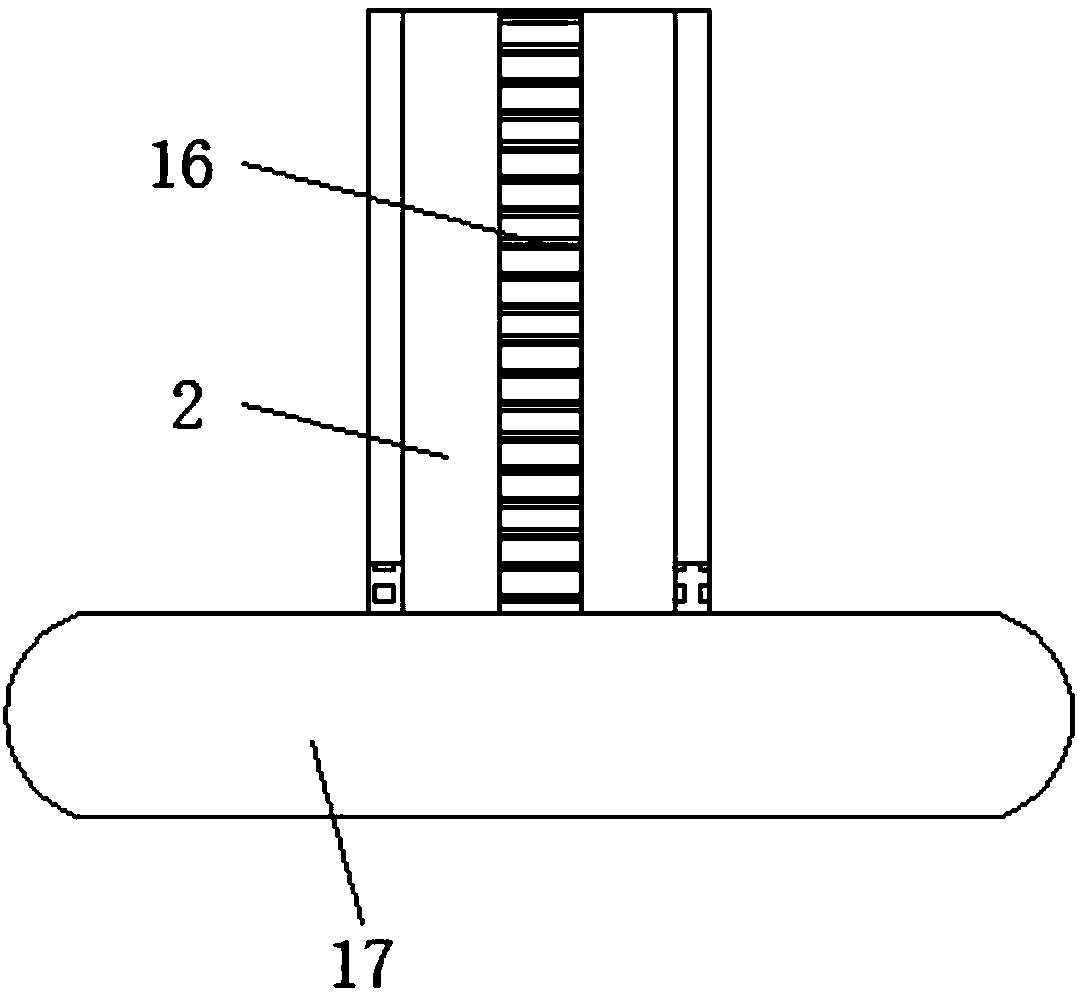

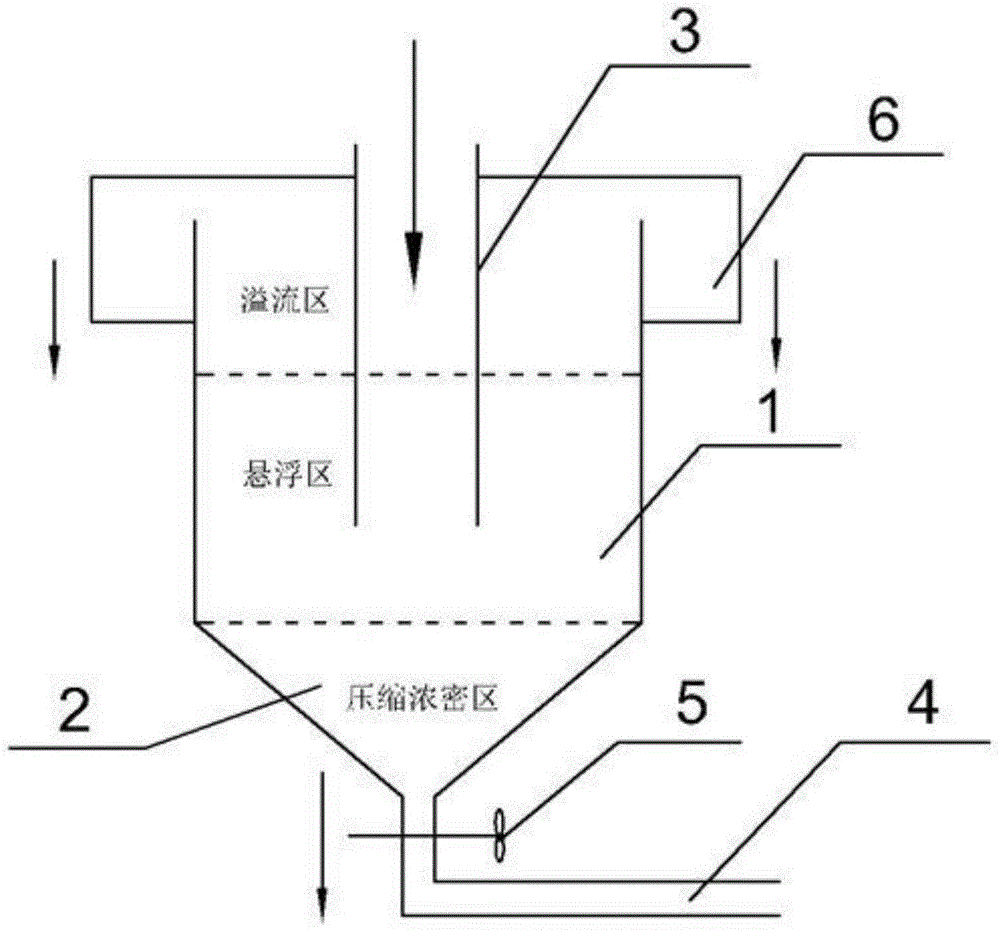

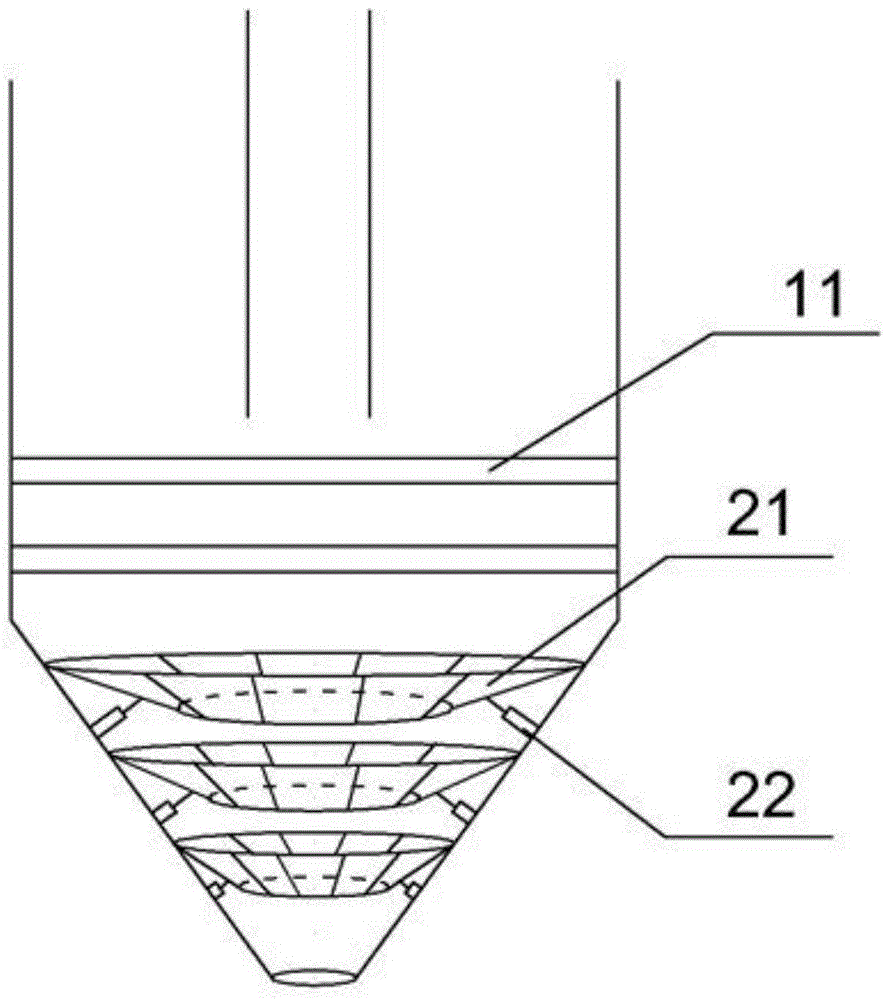

Slurry separation equipment

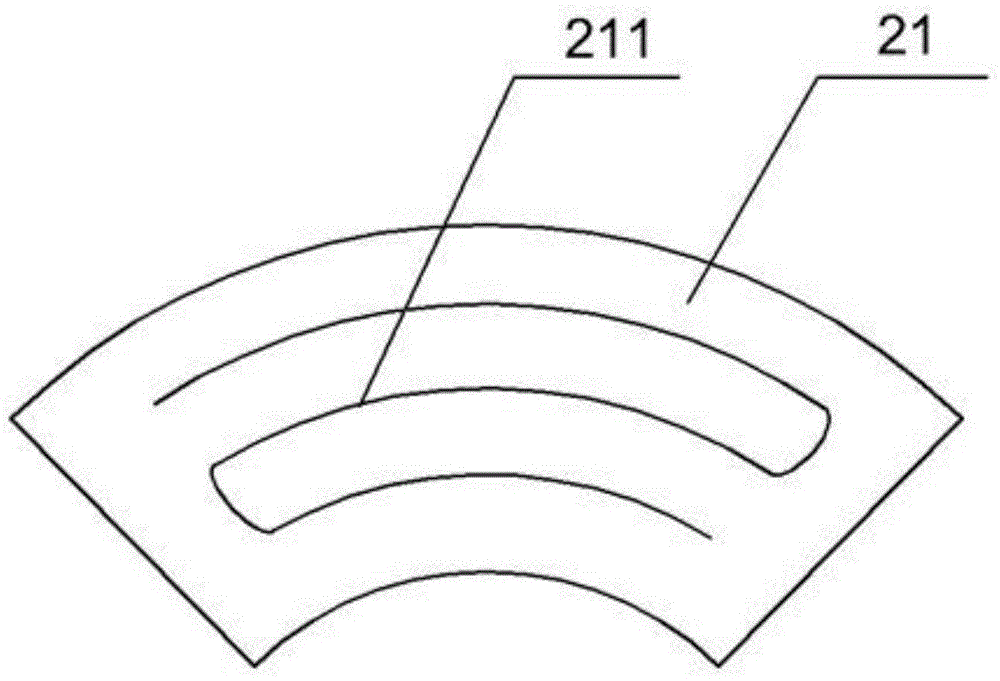

InactiveCN105013219ASimple structureReduce energy consumptionCentrifugal force sediment separationFiltration circuitsDiameter ratioSedimentation

The invention discloses slurry separation equipment which is integrally formed by a first cylindrical portion and a second conical portion with the upward bottom face and the downward peak. A feeding cylinder stretches into the first portion to guide in slurry. Communicating spaces for containing slurry are formed inside the first portion and the second portion. The bottom of the second portion is provided with a slurry discharge opening, a slurry discharge pipe and a valve, wherein separated thick slurry is guided out through the slurry discharge opening, the slurry discharge pipe is communicated with the slurry discharge opening and the valve is connected or disconnected with the slurry discharge pipe. The diameter ratio of the feeding cylinder to the slurry discharge pipe is 4-6:1. Multilayer vortex can be formed naturally, thick slurry sedimentation is promoted due to progressive separation, and the slurry separation equipment has the advantages of being large in sand discharging amount, good in separation effect, high in working efficiency, long in service life and the like.

Owner:广西容县东润陶瓷原料加工场

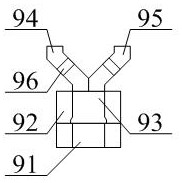

Coke tower decoking device for needle coke production process

ActiveCN112080293AImprove cleanlinessEasy to exportOven incrustations prevention/removalGear wheelLiquid storage tank

The invention provides a coke tower decoking device for a needle coke production process, which belongs to the technical field of decoking equipment, and comprises a coking tower, an eduction tube, aneduction flange, a mounting cover, a driving motor, a driving gear, a driven gear and a scraping jet frame structure, the eduction tube is welded at the lower part of the coking tower; the leading-out flange is welded at the lower part of the leading-out pipe; the mounting cover is mounted at the upper part of the coking tower through bolts; the driving motor is mounted on the right side of the upper part of the mounting cover through bolts; and the driving gear is arranged on the inner side of the mounting cover. Through the arrangement of the liquid pumping pipe, the liquid storage tank andthe booster pump, water liquid in the liquid storage tank is pumped through the liquid pumping pipe by utilizing the booster pump, so that the water liquid is sprayed from the spray head to the innerwall of the coking tower through the liquid guide pipe, the liquid leading-in pipe, the confluence pipe and the inner ring of the sealing bearing and finally through the longitudinal transmission pipe and the transverse material conveying pipe; therefore, the cleanliness of the inner wall of the jet coking tower is improved.

Owner:SHANDONG LIANHUA NEW MATERIAL CO LTD

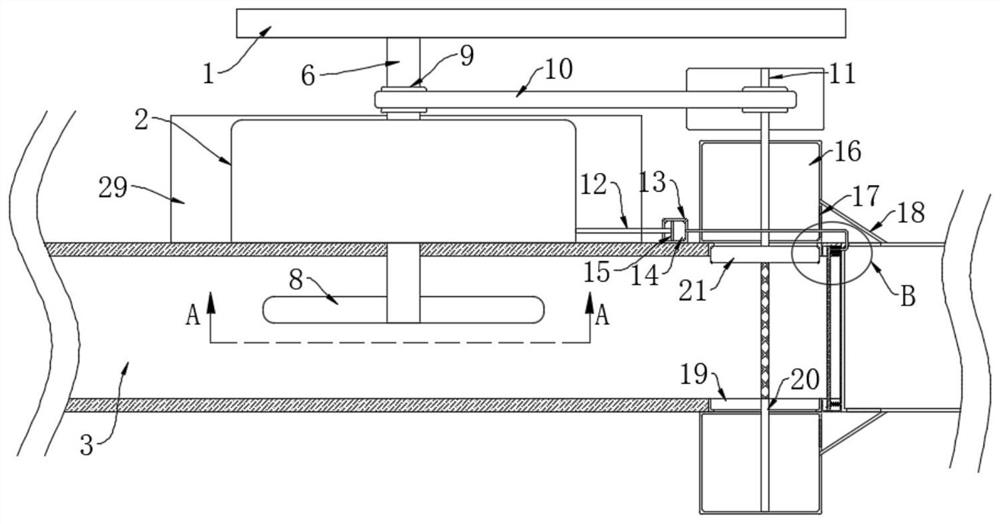

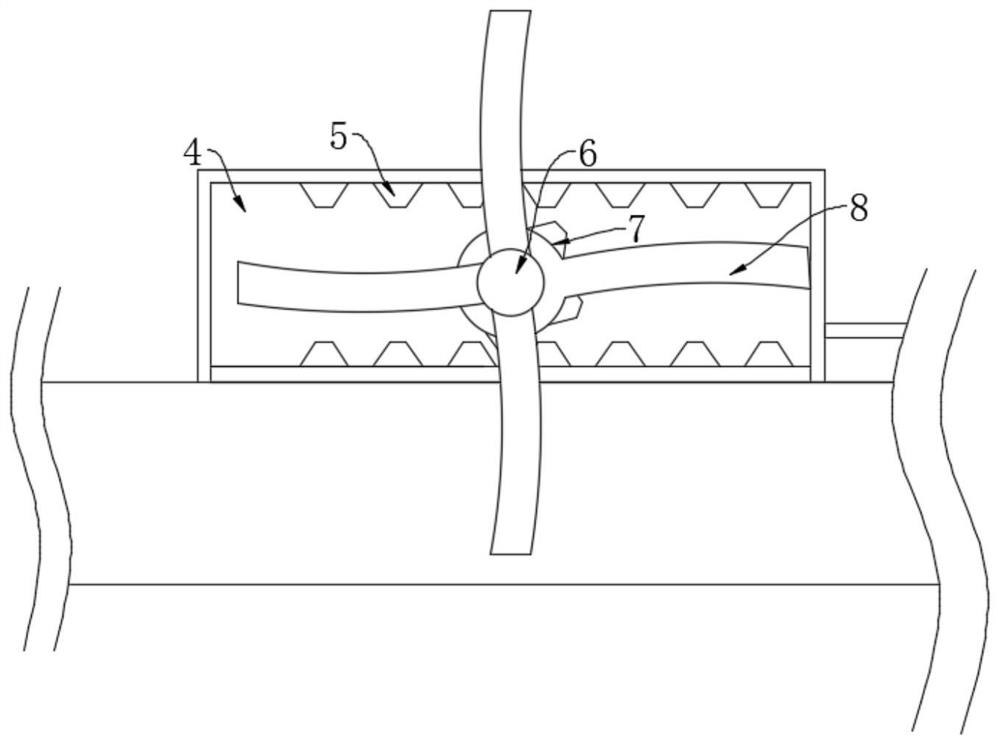

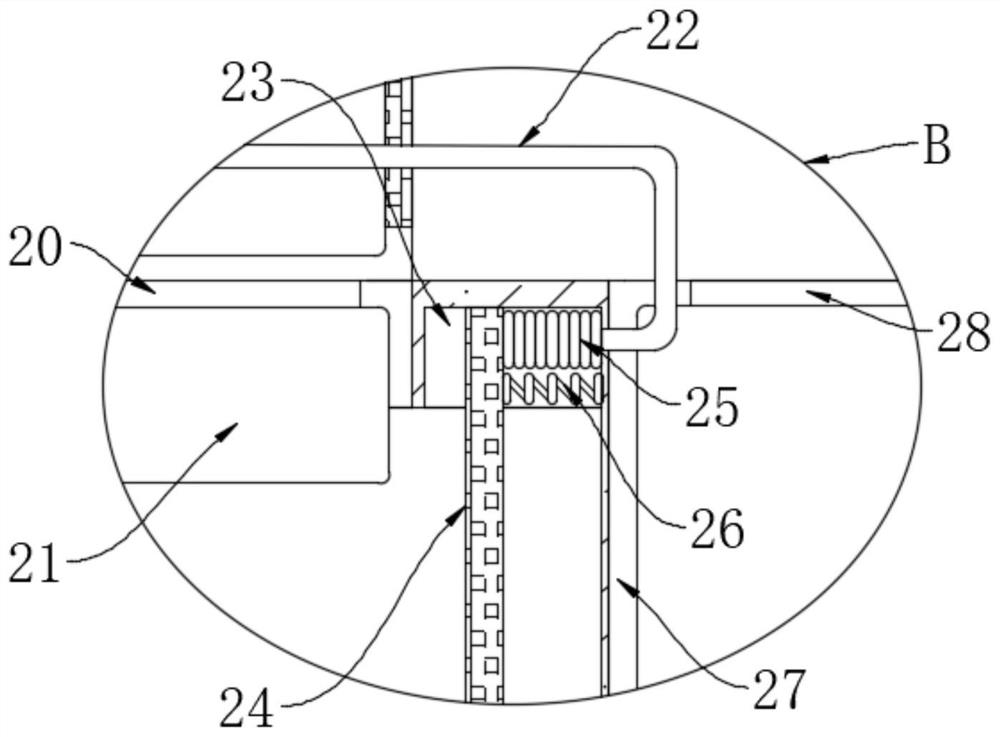

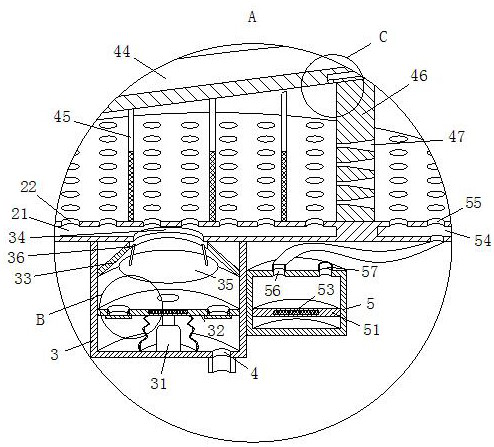

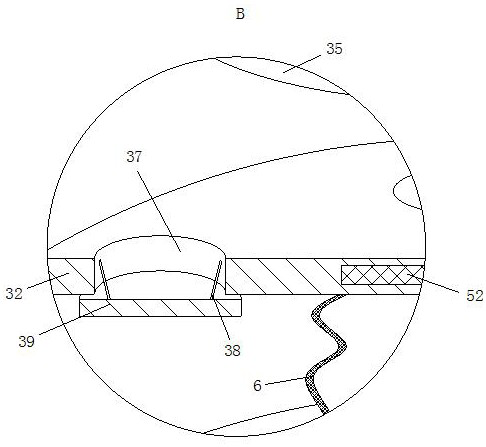

Accumulated water discharging anti-blocking equipment for underground engineering

ActiveCN112031142AImpact emissionsEasy dischargeFatty/oily/floating substances removal devicesSewerage structuresWater dischargeSewage

The invention discloses accumulated water discharging anti-blocking equipment for underground engineering. The equipment comprises a gutter channel and a triggering mechanism, wherein the gutter channel is located at the upper end of the ground, a sliding box is arranged on one side of the gutter channel, a sliding groove matched with the sliding box to move is formed in the ground, the lower endof the sliding box is in sliding connection with the inner bottom of the sliding groove, a transverse plate is arranged behind the side, away from the gutter channel, of the sliding box, the lower endof the transverse plate is fixedly connected with the ground, the right side of the gutter channel communicates with a water discharging pipe, the triggering mechanism comprises a through groove formed in the front side of the sliding box, and a rotating rod is arranged in the through groove. When the equipment is used, garbage in sewage can be treated, so that the situation that drainage is affected due to the fact that a first filter screen is blocked by the garbage is avoided; and the first filter screen can be shaken, so that the situation that the first filter screen is blocked due to too much small garbage is avoided, and the drainage efficiency is improved.

Owner:SUZHOU LIHE INFORMATION TECH CO LTD

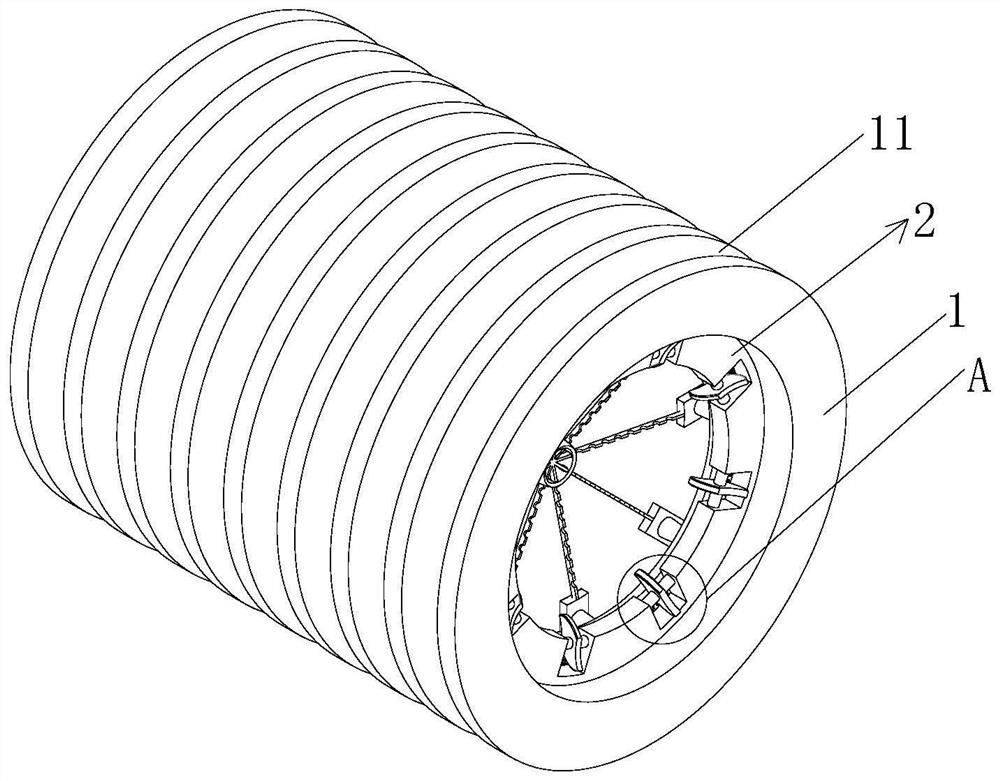

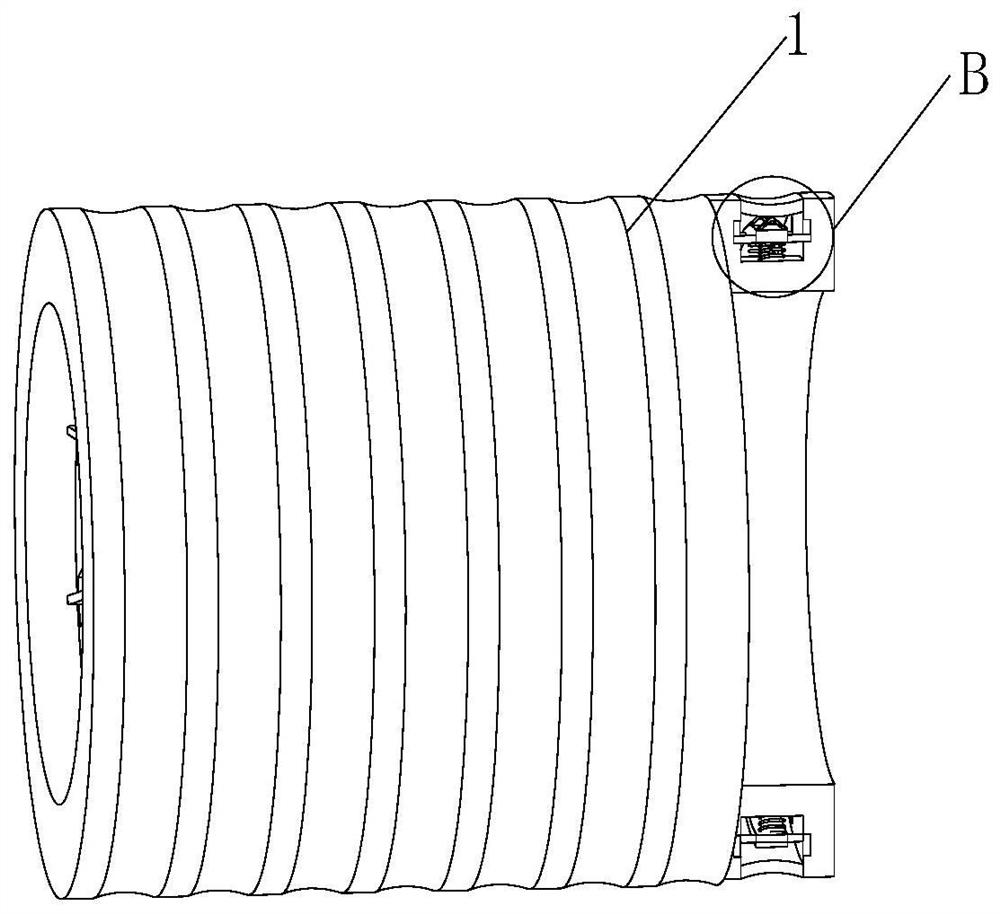

Environment-friendly PVC double-layer axial hollow wall pipe

ActiveCN113198805ATapping regularlyAvoid corrosionHollow article cleaningRigid pipesWater flowEngineering

The invention discloses an environment-friendly PVC double-layer axial hollow wall pipe which comprises a pipe body, a plurality of annular plates are fixedly connected to the surface of the pipe body, the sections of the annular plates are arc-shaped and have elasticity, friction plates are fixedly connected to the surfaces of the annular plates, and a driving mechanism is fixedly connected to the interior of the pipe body. One side of the driving mechanism is fixedly connected with a cleaning mechanism used for cleaning the inner wall of the pipe body, the surface of the pipe body is fixedly connected with a plurality of auxiliary pressure-resistant mechanisms, and the auxiliary pressure-resistant mechanisms are located between the surface of the pipe body and the annular plates. According to the environment-friendly PVC double-layer axial hollow wall pipe, compared with the prior art, through the power of water flow, driving blocks can rotate on fixed shafts, the driving blocks can regularly knock one side of a movable plate, the movable plate can be pushed to move on fixed rods, the inner wall of a pipe can be cleaned through elastic bristles, impurities are prevented from being accumulated on the inner wall of the pipe, the inner wall of the pipe is prevented from being corroded, and the service life of the pipe is prevented from being influenced.

Owner:瑞腾建材集团股份有限公司

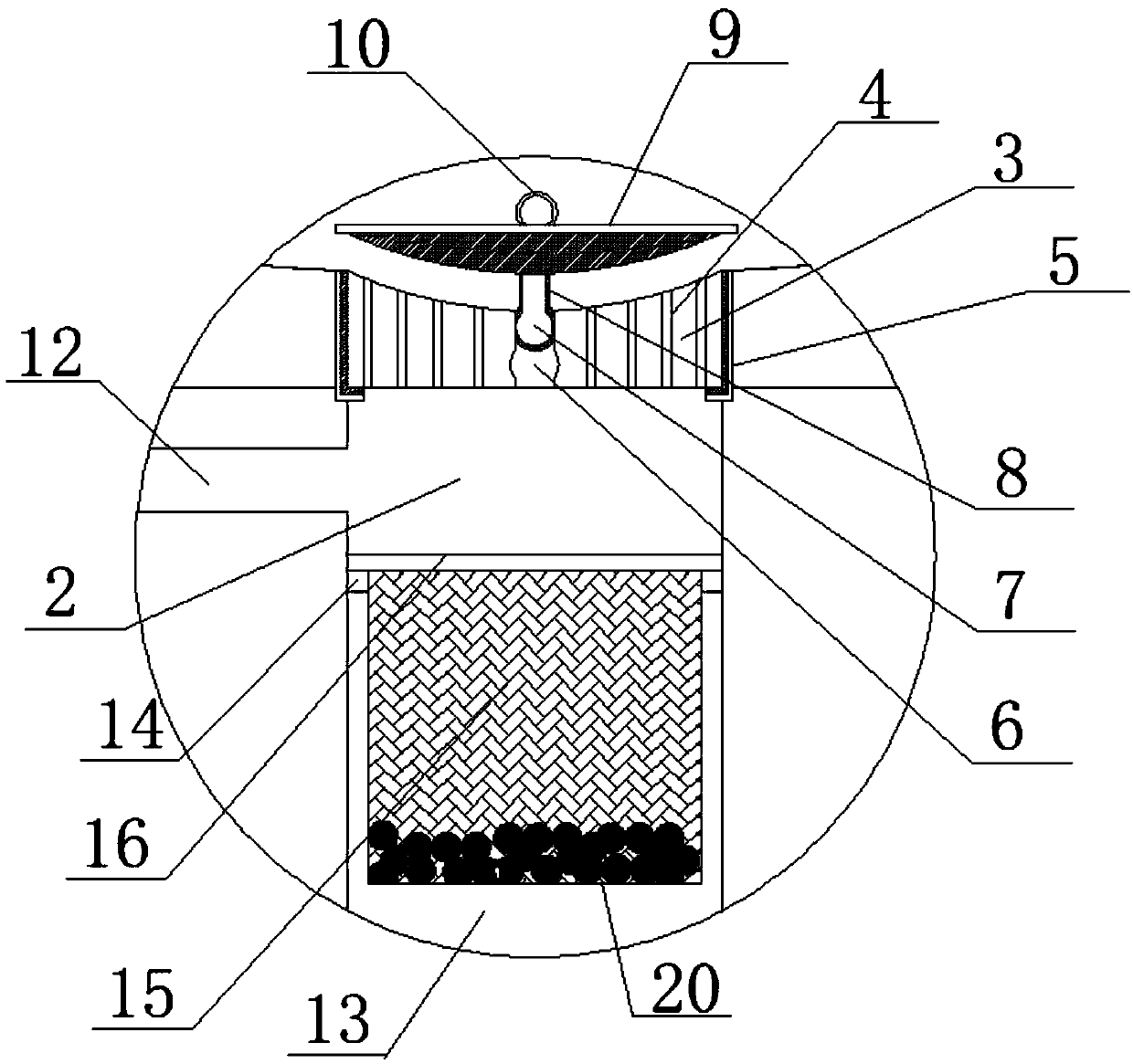

Domestic sewage environmental filtering drain tank

The invention belongs to the technical field of sewage filtration and discloses a domestic sewage environmental filtering drain tank. The domestic sewage environmental filtering drain tank comprises avegetable basin, a link pipe, a filter cake, a sealing cover, an overflow pipeline, a first sewage pipeline, a lift cage and a second sewage pipeline. Through an overflow opening provided with a filter screen, water in the vegetable basin can be prevented from overflowing out of the vegetable basin, and residue in the vegetable basin can be prevented from flowing into the overflow pipeline through the overflow opening so as to avoid the sewer from being clogged. With the filter cake disposed in a circular hole and through rubber sealing, the filter cake can be taken and residue is convenientto clean. Through the arrangement of the lift cage and by putting multiple freely-placed balls in the lift cage, a flexural slit is formed, fine residues can be filtered in the lift cage, and a lift cage hole will not be blocked and discharge of sewage will not be affected. Through the arrangement of a baffle plate, discharge of sewage will not be affected, and pollution caused by sewage backflowalso can be prevented.

Owner:芜湖杰汇环保科技有限公司

Meat auxiliary processing equipment

ActiveCN114868792AQuick cutGuaranteed stabilityMeat holding apparatusSkinning instrumentsPork meatEngineering

The invention provides meat auxiliary processing equipment in the technical field of meat product processing. The meat auxiliary processing equipment comprises a pressure feeding channel, a pressure feeding channel and a pressure feeding channel, wherein pigskin always faces downwards and is horizontally output; the cutting assembly is used for cutting the pork skin and is arranged on one side of the pressure feeding channel; the refrigerating assembly is arranged below the cutting assembly in a cutting manner; the refrigeration assembly comprises a refrigeration roller used for positioning the pigskin cutting position, and the refrigeration roller is installed below the pressure feed channel. Spiral channels used for spraying liquid nitrogen to the pork skin and conveying the pork skin to the two sides are distributed on the refrigeration roller. According to the invention, through mutual cooperation between the pressure feeding channel and the refrigeration assembly, the pressure feeding channel arranges the pork skin downwards and conveys the pork skin to the refrigeration roller, and the pork skin is quickly frozen by the refrigeration roller, so that the frozen pork skin is quickly cut, and the device has the advantages of being particularly suitable for quickly peeling pork products, high in uniformity of the removed pork skin and the like.

Owner:安徽鑫松亚食品科技股份有限公司

Printing ink wastewater treatment and purification device

ActiveCN111871063AImpact emissionsAffect purificationFiltration circuitsThreaded pipeProcess engineering

The invention belongs to the technical field of wastewater purification, and particularly relates to a printing ink wastewater treatment and purification device which comprises a purification tank anda settling tank; the purifying box is fixedly connected to the upper surface of the settling box; a water inlet is formed in the upper surface of the purification box, and a water outlet is formed inthe side wall of the purification box; activated sludge is filled in the purification box; the water outlet is positioned above the activated sludge; the outer surface of the purification box is fixedly wrapped with a threaded pipe; one end of the threaded pipe is communicated with the water outlet, and the other end is communicated into the settling tank on the upper surface of the settling tank; a collecting tank is formed in the inner wall of the bottom of the settling tank; the collecting tank is communicated with the interior of the settling tank through collecting holes which are uniformly distributed; the bottom of the settling tank is fixedly connected with a backflow tank. According to the invention, cyclic utilization of activated sludge can be realized, the utilization efficiency is effectively improved, resource consumption is saved, and the purification efficiency is improved.

Owner:安徽华哲标签科技有限公司

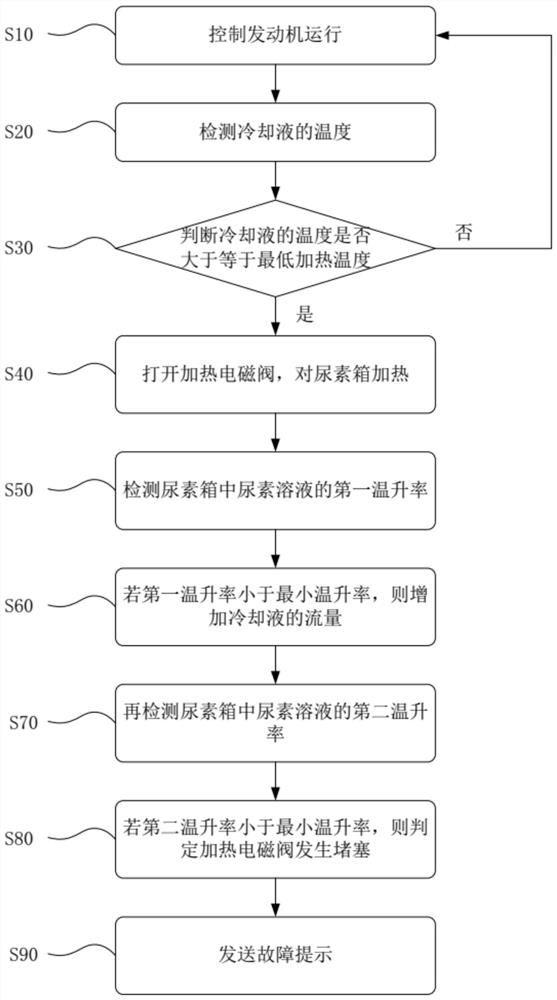

Method for detecting blockage of heating electromagnetic valve of urea box and engine

ActiveCN113700540AReduce false positive rateHigh trafficInternal combustion piston enginesExhaust apparatusUreaEngineering

The invention discloses a method for detecting blockage of a heating electromagnetic valve of a urea box and an engine, and relates to the technical field of engines. The urea box is heated through cooling liquid, and the heating electromagnetic valve is used for controlling whether the cooling liquid communicates with the urea box or not. The method for detecting blockage of the heating electromagnetic valve of the urea box comprises the following steps: opening the heating electromagnetic valve, and heating the urea box; detecting a first temperature rise rate of a urea solution in the urea box; if the first temperature rise rate is smaller than the minimum temperature rise rate, the flow of the cooling liquid is increased; detecting a second temperature rise rate of the urea solution in the urea box; if the second temperature rise rate is smaller than the minimum temperature rise rate, judging that the heating electromagnetic valve is blocked. According to the method for detecting blockage of the heating electromagnetic valve of the urea box, the phenomenon of slow temperature rise or no temperature rise of the urea box caused by small flow of the cooling liquid is eliminated, and the misjudgment rate is effectively reduced.

Owner:WEICHAI POWER CO LTD

Blow-down valve with dirt collecting function

The blow-down valve with the dirt collecting function comprises a lower valve seat connected with a blow-down pipeline, an upper valve seat is fixedly installed on the outer side of the lower valve seat, a valve rod is installed in the upper valve seat, and a sealing plug is fixedly installed at the lower end of the valve rod; the movable ring is movably arranged on the inner side of the lower valve seat; the flow guide hole is formed between the lower valve seat and the collecting seat, and a containing groove is formed in the side wall of the flow guide hole; the drain outlet is formed in the lower surface of the left end of the collecting seat, and the inner side of the drain outlet is in shaft connection with a blocking plate; the shaft rod is in shaft connection with the inner side of the collecting seat, and an impeller is arranged on the outer side of the shaft rod. According to the blow-down valve with the dirt collecting function, large-particle impurities in sewage can be automatically filtered and blocked, abrasion of the valve assembly is effectively avoided, meanwhile, the filtered impurities can be automatically collected and discharged under the driving effect of water flow, and practicability is high.

Owner:吕佳浩

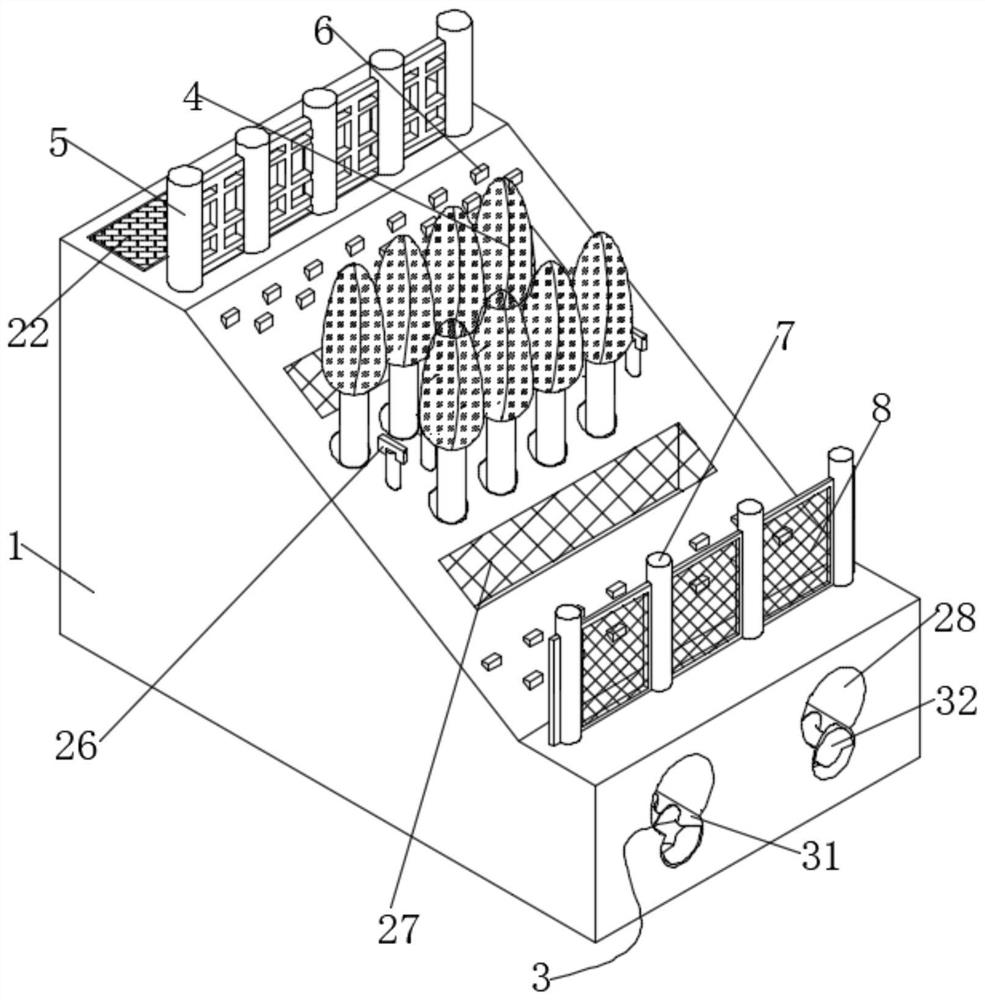

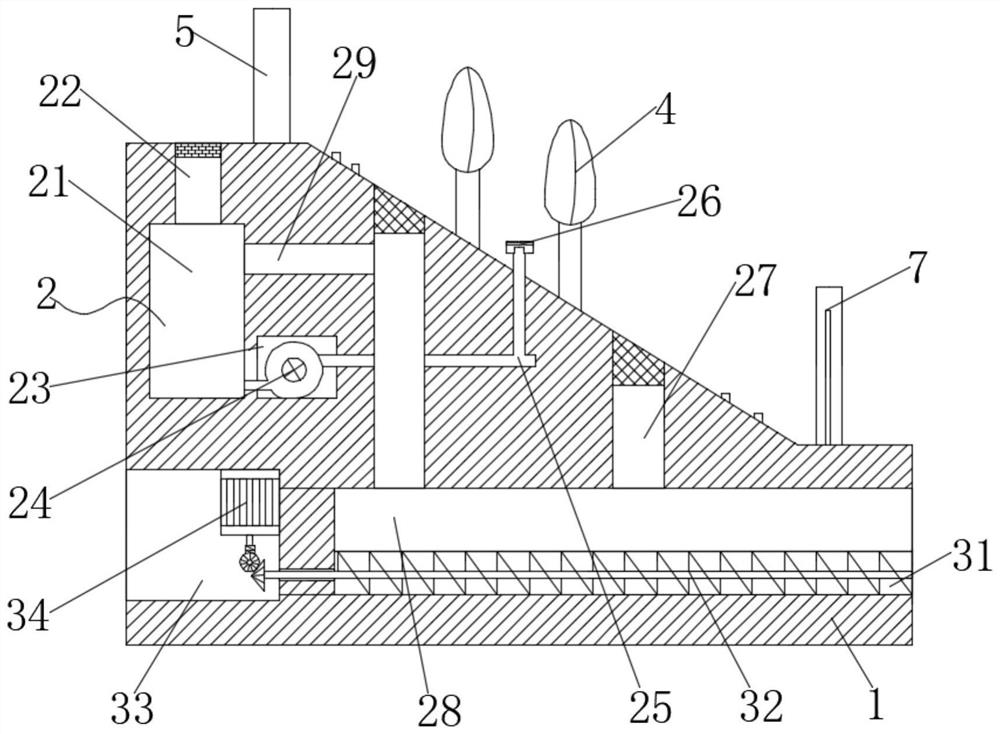

Hydraulic engineering ecological slope protection and construction method

InactiveCN111851410AAvoid churnAvoid accumulationGeneral water supply conservationSewer cleaningEnvironmental engineeringHydraulic engineering

The invention discloses a hydraulic engineering ecological slope protection comprising a slope body, a drainage component and a mud removal component. The drainage component is arranged on the inner part of the slope body, and the mud removal component is arranged on the inner wall of the slope body and below the drainage component; a catch basin is arranged inside the slope body, a first drainagechannel is arranged on the outer wall of the top end of the slope body, corresponding to the catch basin, the first drainage channel is in through connection with the catch basin, a first mounting groove is arranged in the inner portion of the slope body and is positioned on one side of the catch basin, a water pump is fixed on the inner wall of the bottom end of the first mounting groove througha bolt, and one end of a water inlet of the water pump is in through connection with one side of the catch basin. According to the drainage assembly, the catch basin is used for collecting rainwater,the rainwater can be recycled, resources are saved, the mud removal component is arranged so that mud and garbage in a mud removal water channel can be cleaned out, and the mud and the garbage are prevented from being accumulated to influence the drainage of the water channel. The hydraulic engineering ecological slope protection is simple in structure, convenient to operate and practical.

Owner:信阳市水利勘测设计院

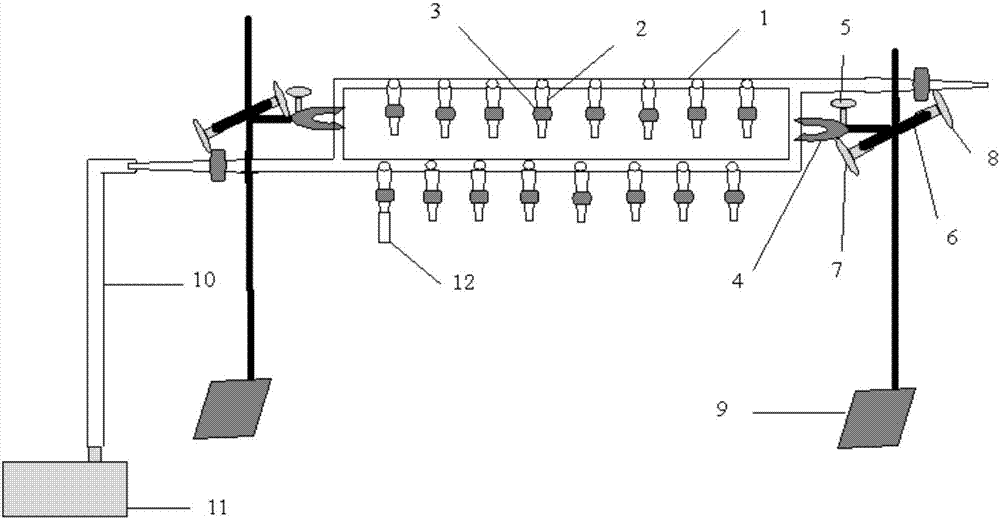

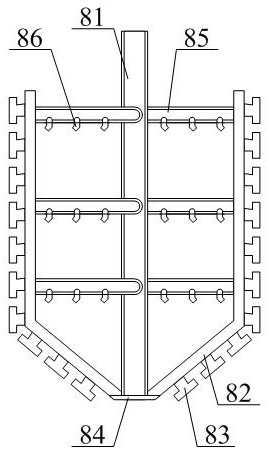

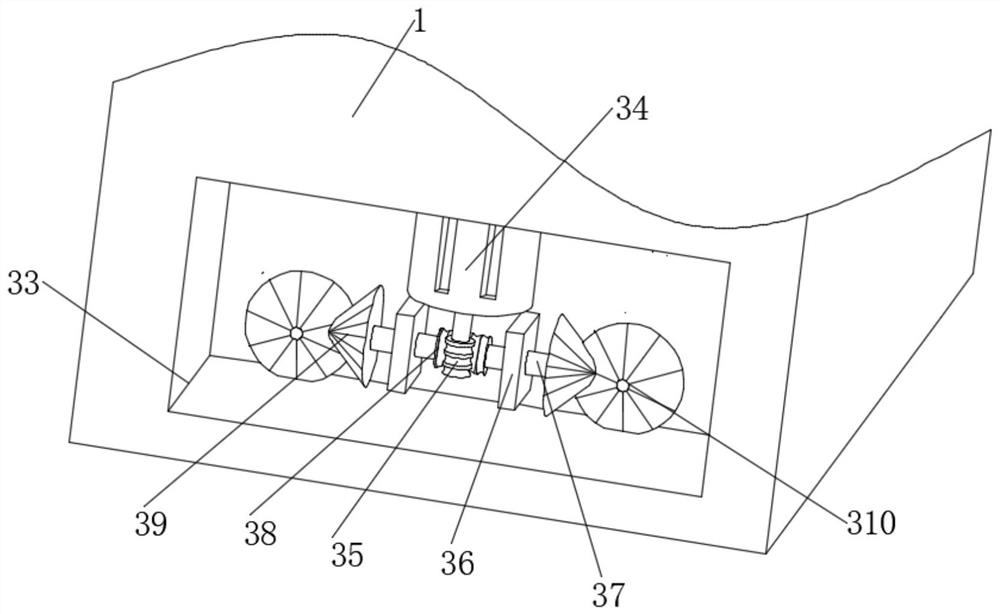

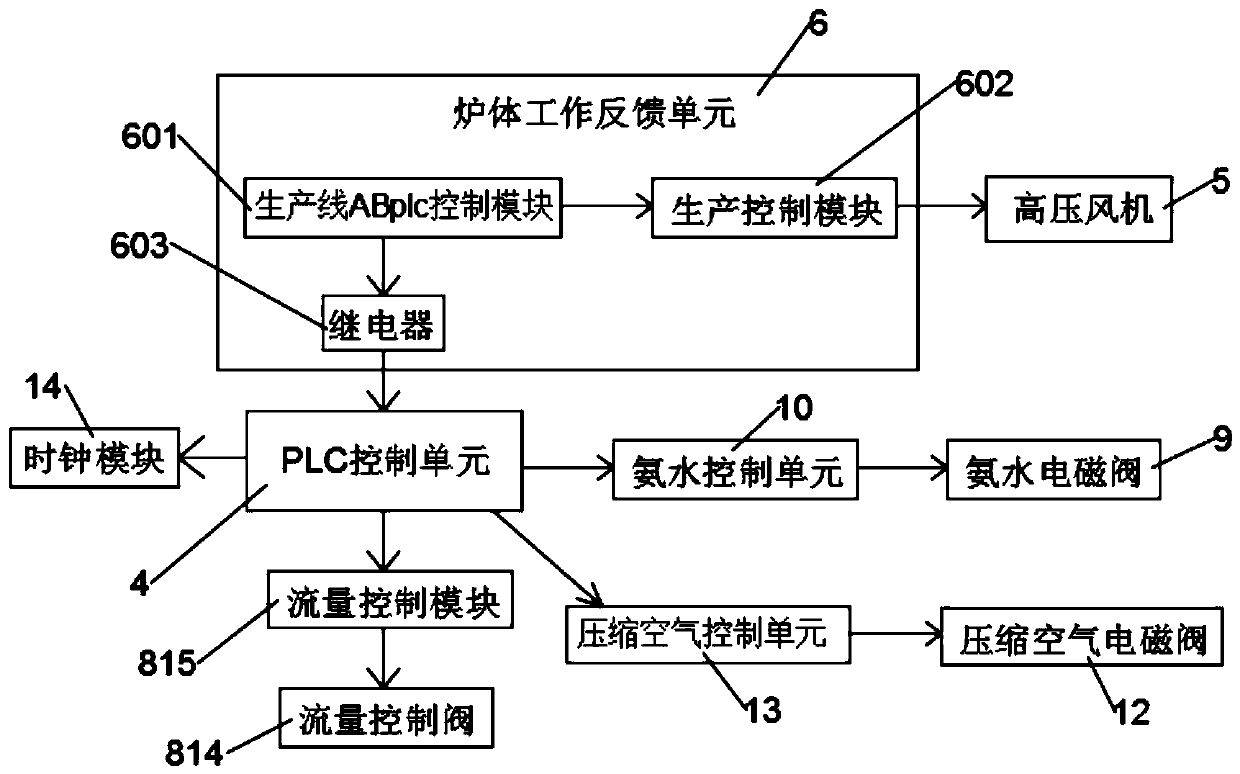

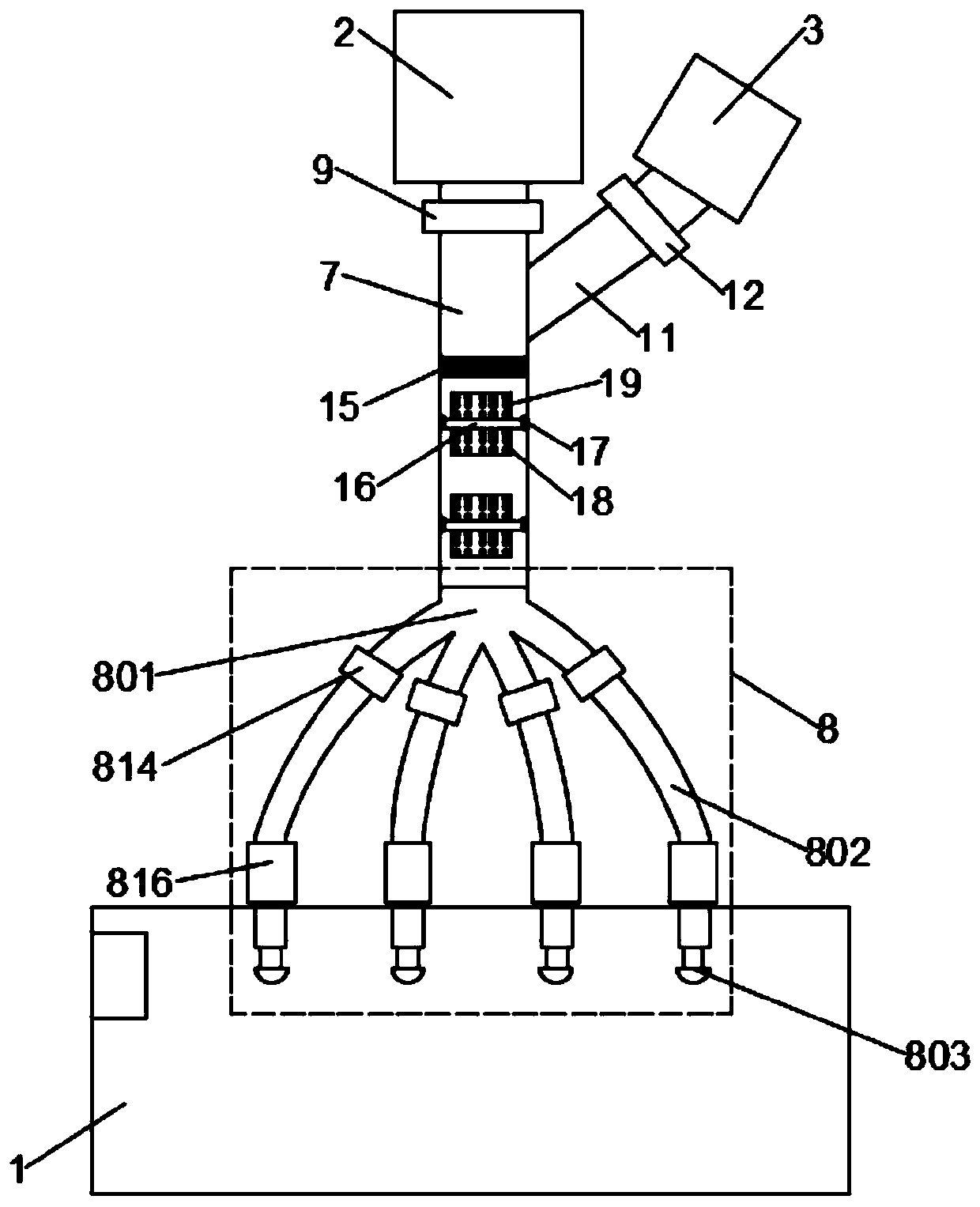

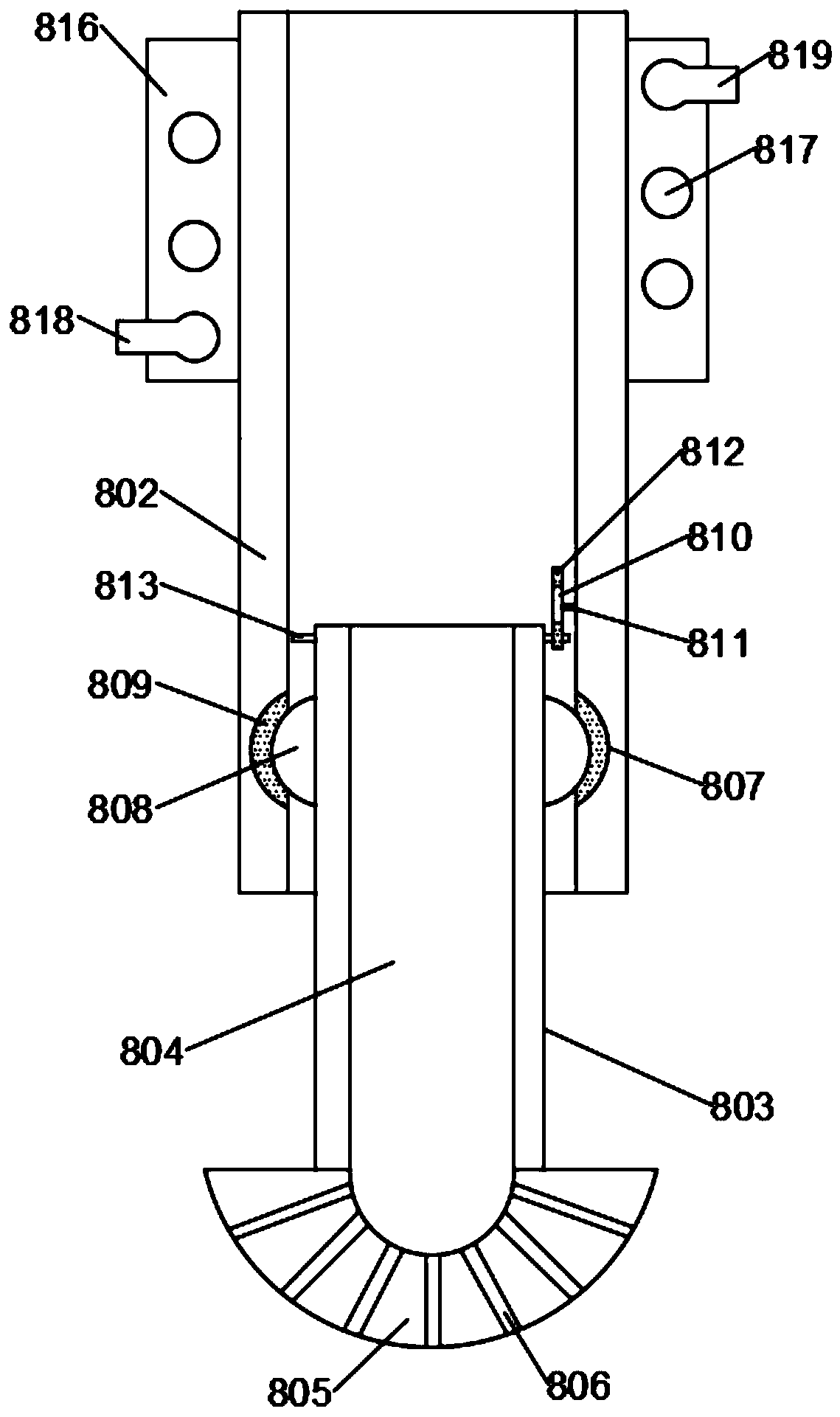

Ammonia spraying control system

InactiveCN110302671ARealize intelligent sprayingAchieve denitrificationDispersed particle separationProduction lineSlag

An embodiment of the invention discloses an ammonia spraying control system which comprises a boiling furnace, an ammonia water pump, an air compressor pump and a PLC (programmable logic controller) control unit. A high-pressure fan is mounted on the boiling furnace and connected with the PLC control unit through a furnace working feedback unit, an ammonia water pipe is connected at the output endof the ammonia water pump and connected with the boiling furnace through a uniform spraying structure, and a compressed air pipe is connected at the output end of the air compressor pump and connected with the ammonia water pipe. According to the ammonia spraying control system, ammonia water can be intelligently sprayed, an ammonia spraying device can be automatically started when the furnace isstarted, the ammonia spraying device can automatically stop when the furnace is pressed due to failure of a production line or other reasons, caking of slag in the boiling furnace is avoided, the ammonia water can be sprayed to various directions in the boiling furnace, and ammonia gas is more uniformly distributed in the boiling furnace. Besides, according to the system, the ammonia water cannotbe evaporated before entering the boiling furnace, and the influence of increasing of pressure in an ammonia spraying pipe on follow-up spraying of the ammonia water is avoided.

Owner:北新建材(苏州)有限公司 +1

A coke tower decoking device for needle coke production process

ActiveCN112080293BImprove cleanlinessEasy to exportOven incrustations prevention/removalElectric machineGear wheel

The invention provides a coking tower decoking device used in the production process of needle coke, which belongs to the technical field of coking equipment and includes a coking tower, an outlet pipe, an outlet flange, a mounting cover, a driving motor, a driving gear, a driven gear and Scraping spray rack structure, the outlet pipe is welded at the lower part of the coking tower; the outlet flange is welded at the lower part of the outlet pipe; the installation cover bolt is installed at the upper part of the coking tower; the drive motor bolt It is installed on the upper right side of the installation cover; the driving gear is arranged on the inner side of the installation cover. The arrangement of the liquid suction pipe, the liquid storage tank and the booster pump of the present invention uses the booster pump to extract the water liquid in the liquid storage tank through the liquid suction pipe, so as to pass through the catheter tube, the liquid introduction tube, the confluence tube and the sealed bearing Finally, through the longitudinal transmission pipe and the transverse feed pipe, the water is sprayed from the nozzle to the inner wall of the coking tower, thereby increasing the cleanliness of the inner wall of the spraying coking tower.

Owner:SHANDONG LIANHUA NEW MATERIAL CO LTD

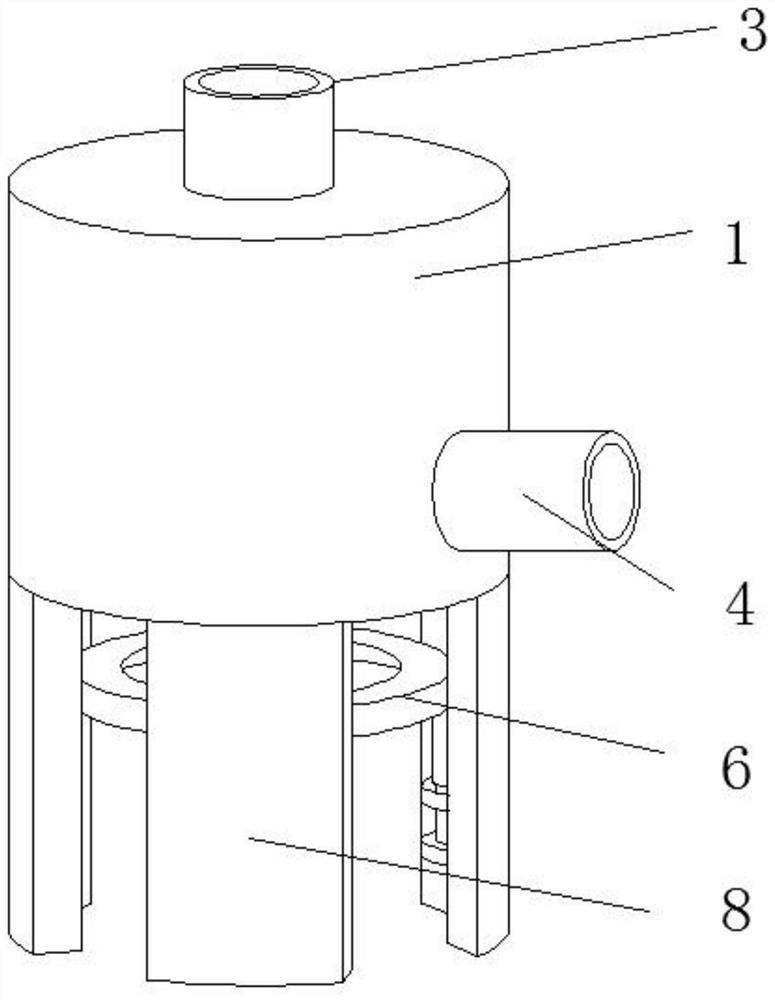

Dry fermentation device of straw

InactiveCN107744164AIncrease the effective contact areaSpeed up contactFeeding-stuffEngineeringFermentation

A straw dry fermentation device, comprising a fermentation chamber, a sealing cover is arranged on the top of the fermentation chamber, an auxiliary material inlet pipe is arranged on one side of the upper surface of the sealing cover, and an auxiliary material adding chamber is welded on the top of the auxiliary material inlet pipe, the auxiliary material The inside of the inlet pipe is provided with a spring tube and a supporting plate used with it. The outer wall of the vacuum plate is fixed with a water pump, and the water pump is connected to the spray pipe in the fermentation bin through a hose. A filter plate is arranged on the wall, and a primary storage bin is arranged under the filter plate, a secondary storage bin is arranged below the primary storage bin, an air outlet pipe is arranged at the center of the sealing cover, and the inner surface wall of the air outlet pipe is provided with In the drying plate, an expansion sleeve is sleeved on the surface of the air outlet pipe, and a clamping groove is opened on the surface of the expansion sleeve. The overall structural design of the fermentation device is simple and reasonable, realizes the effect of rapid fermentation, avoids environmental pollution, and has strong practicability.

Owner:利川隆祥生物科技有限公司

Slurry Separation Equipment

InactiveCN105013219BAchieve separationAchieving Progressive SeparationCentrifugal force sediment separationFiltration circuitsDiameter ratioSlurry

The invention discloses slurry separation equipment which is integrally formed by a first cylindrical portion and a second conical portion with the upward bottom face and the downward peak. A feeding cylinder stretches into the first portion to guide in slurry. Communicating spaces for containing slurry are formed inside the first portion and the second portion. The bottom of the second portion is provided with a slurry discharge opening, a slurry discharge pipe and a valve, wherein separated thick slurry is guided out through the slurry discharge opening, the slurry discharge pipe is communicated with the slurry discharge opening and the valve is connected or disconnected with the slurry discharge pipe. The diameter ratio of the feeding cylinder to the slurry discharge pipe is 4-6:1. Multilayer vortex can be formed naturally, thick slurry sedimentation is promoted due to progressive separation, and the slurry separation equipment has the advantages of being large in sand discharging amount, good in separation effect, high in working efficiency, long in service life and the like.

Owner:广西容县东润陶瓷原料加工场

An indoor soil cultivation device integrating aeration cultivation and gas collection and its application

ActiveCN106940365BSimple structureEasy to manufactureWithdrawing sample devicesPreparing sample for investigationGas collecting tubeEngineering

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

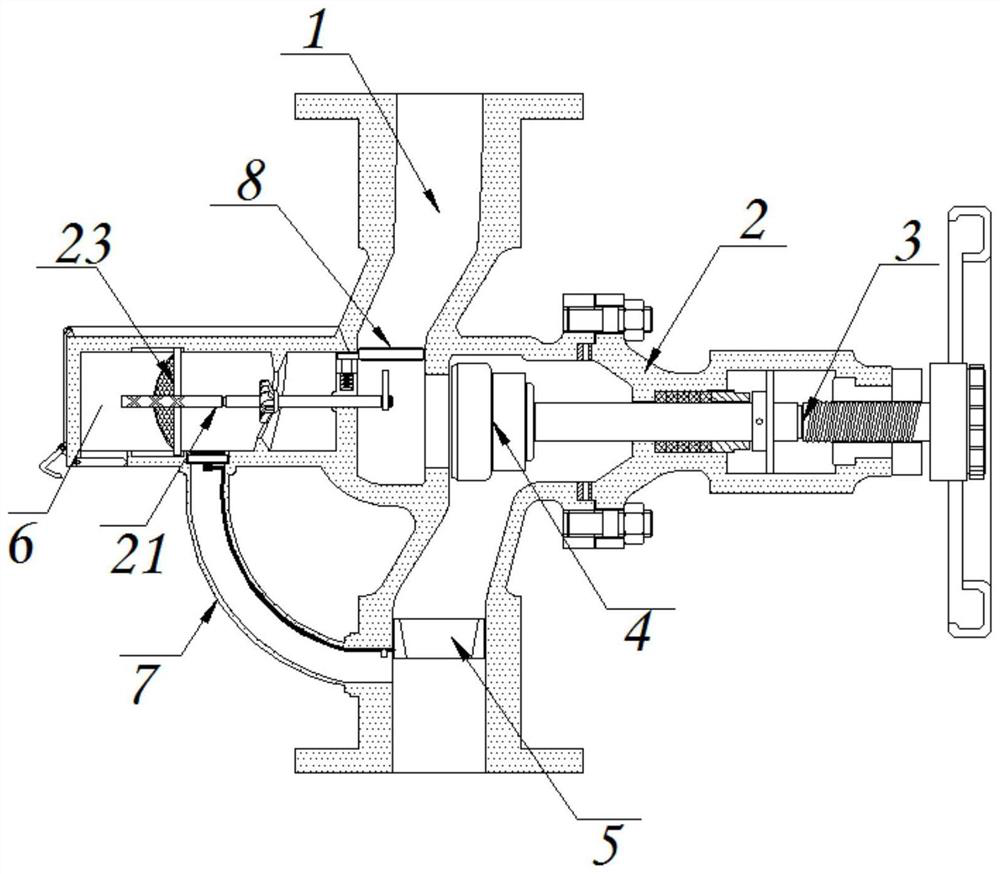

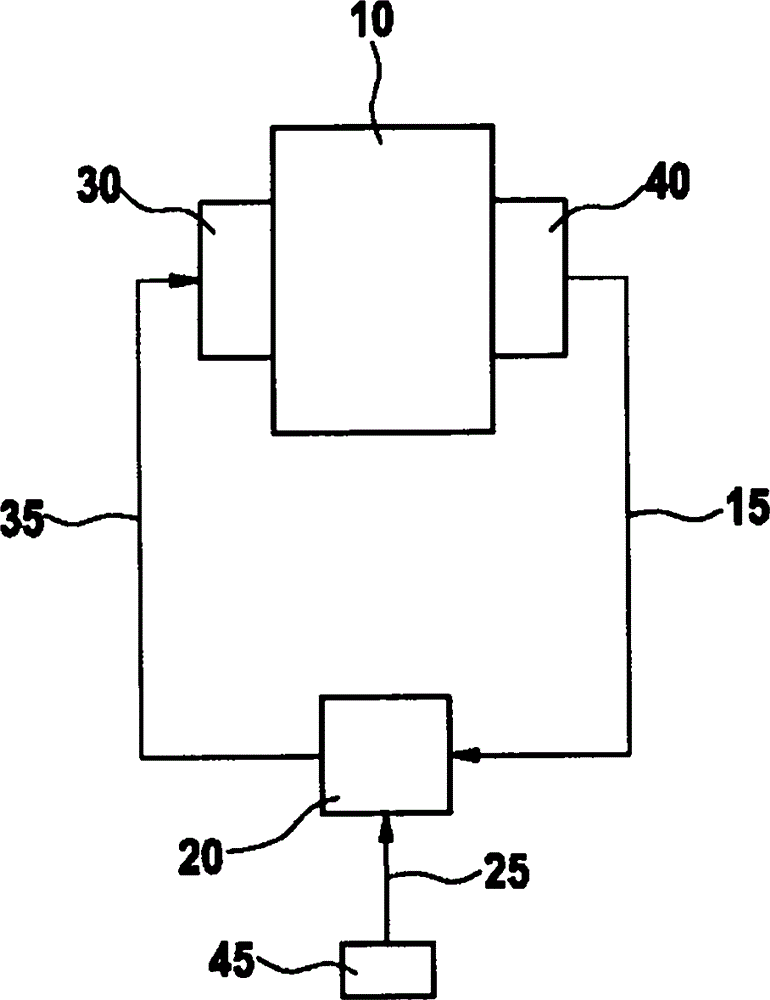

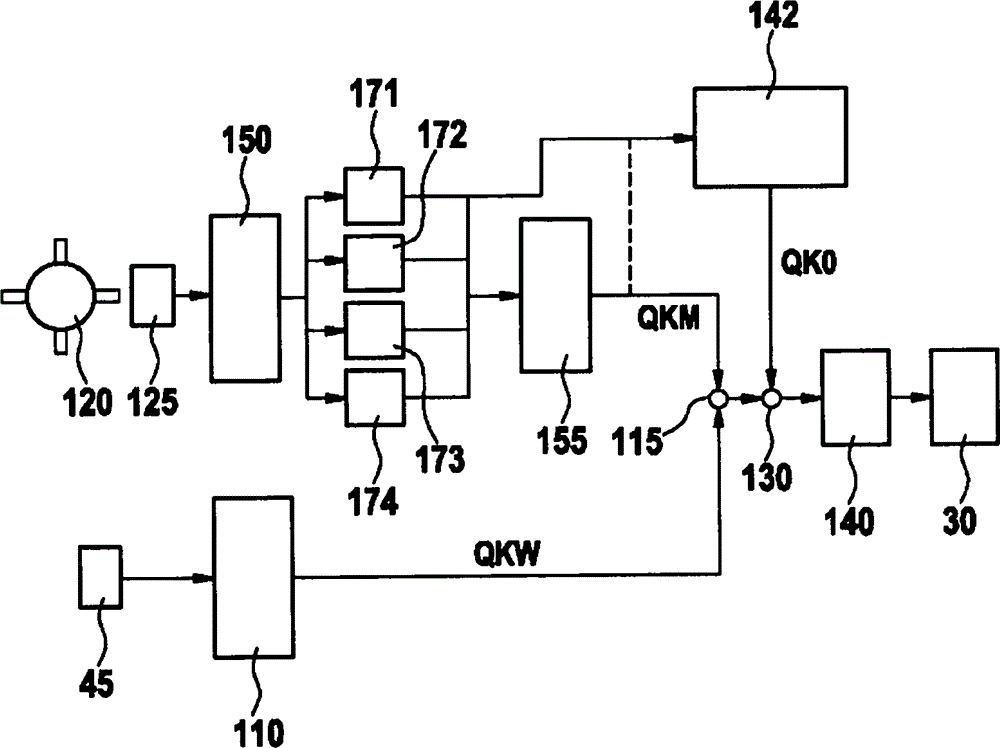

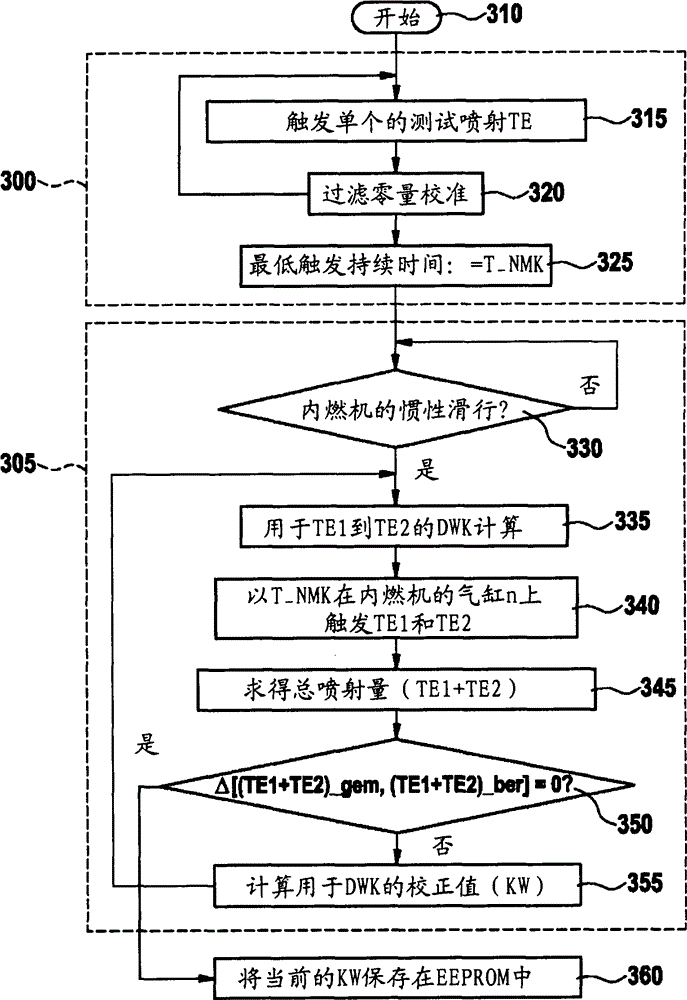

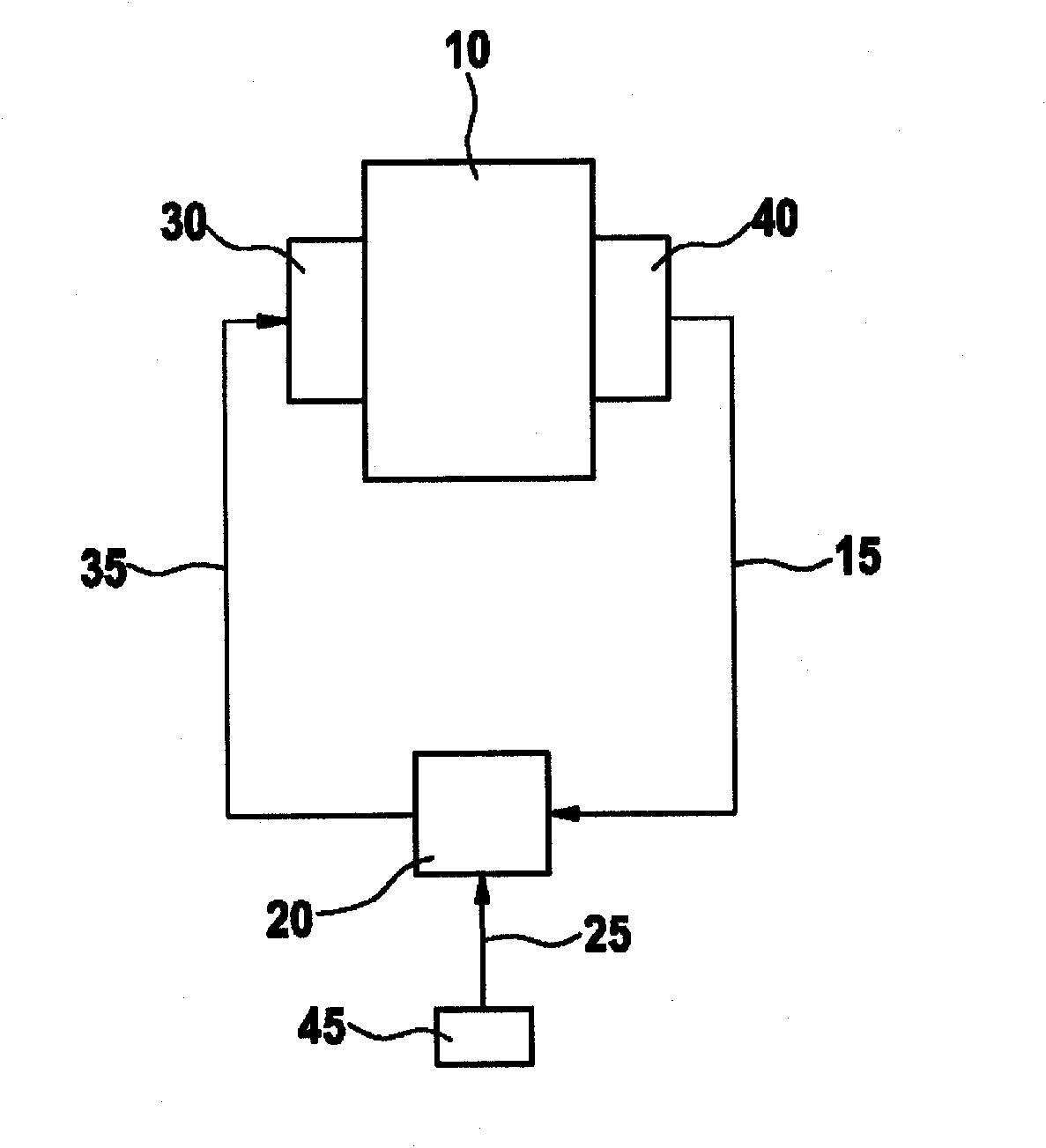

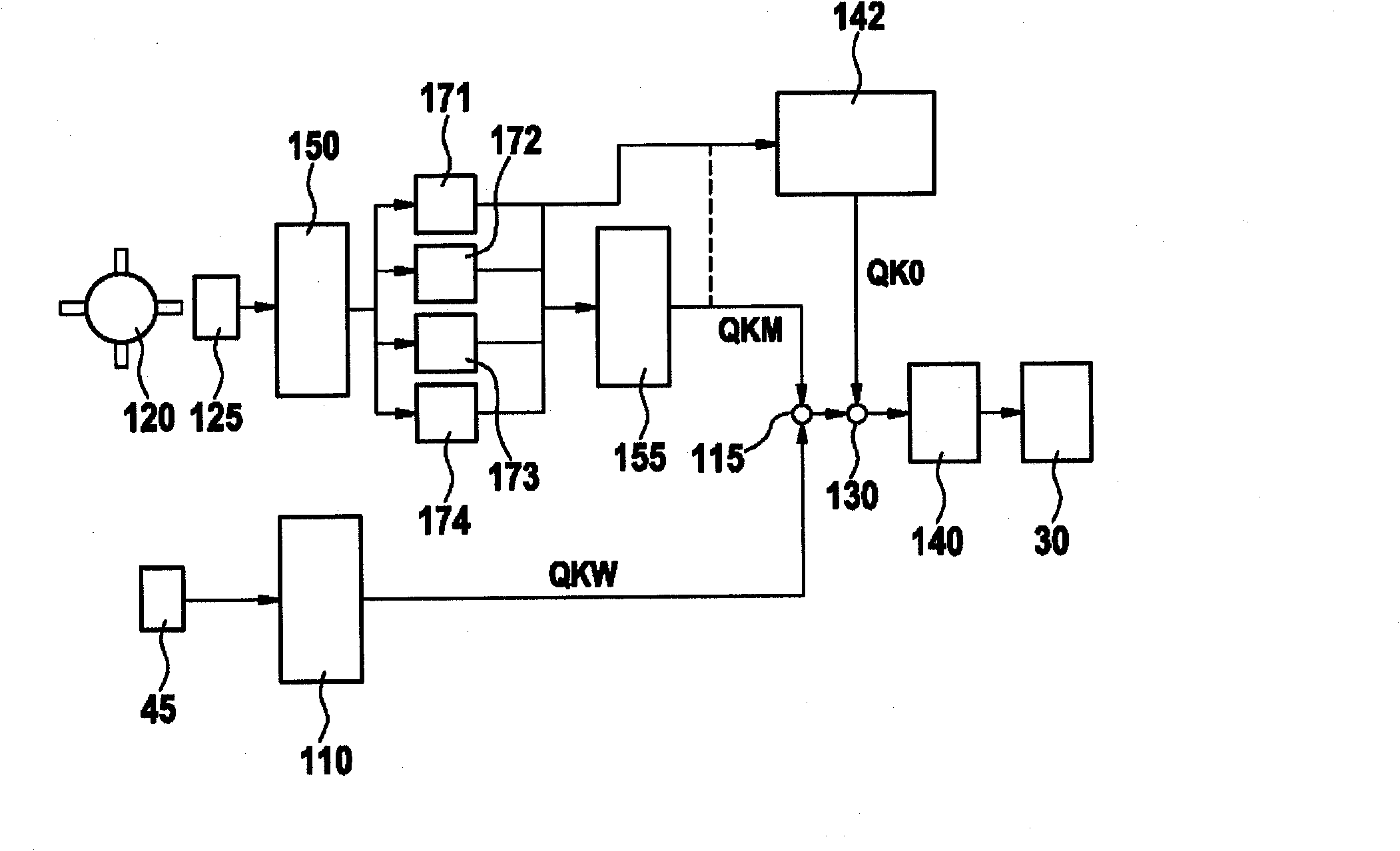

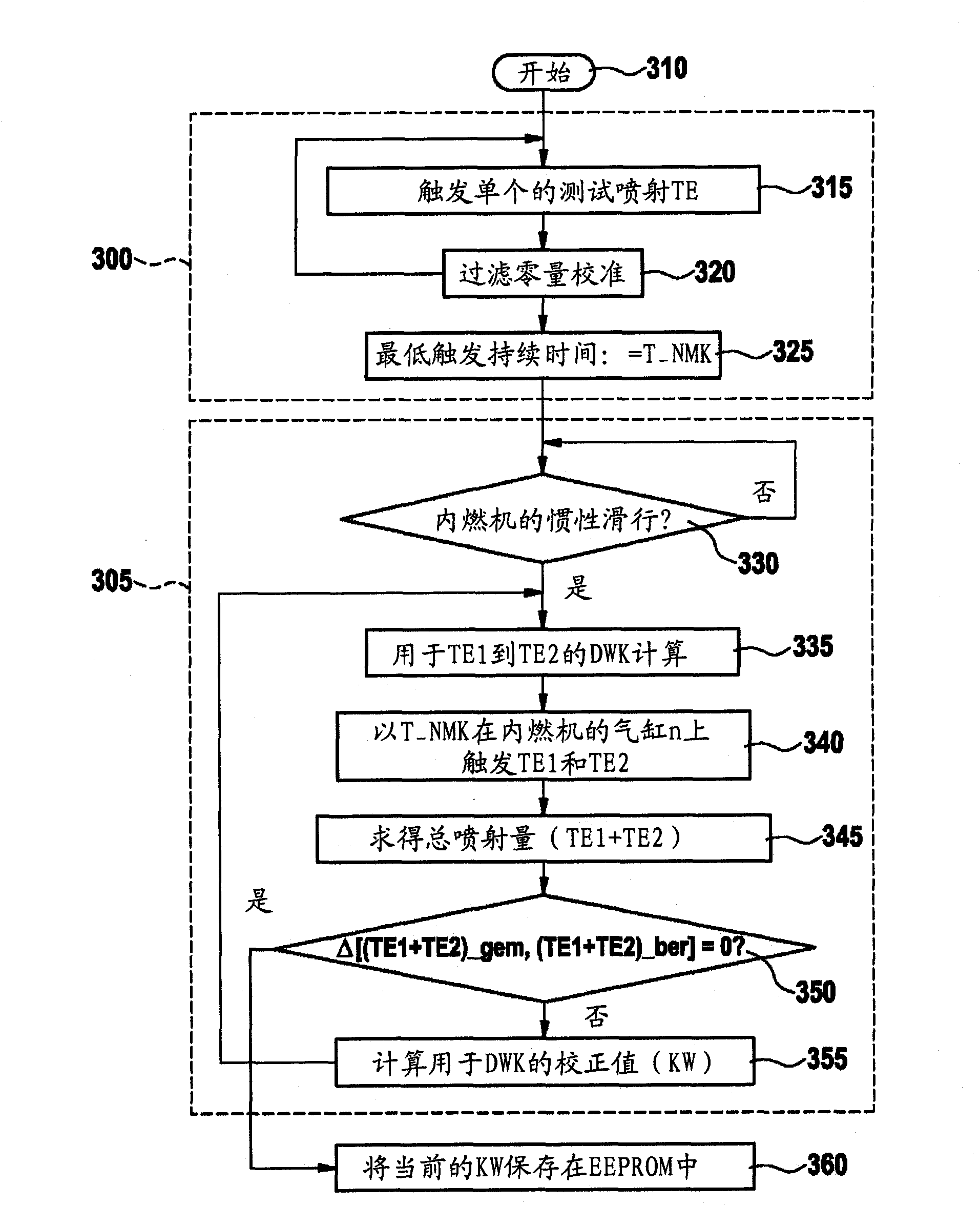

Method and device for the pressure wave compensation of consecutive injections in an injection system of an internal combustion engine

InactiveCN102084110BImpact emissionsReduce rated value set pointElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

A method and a device for controlling an injection system of an internal combustion engine are described, in which at least two consecutive partial injections are compensated for using pressure wave compensation, it is provided in particular that two test injections having a specified time interval to one another are triggered in a cylinder of the internal combustion engine, the total injection quantity of the at least two partial injections is ascertained, and a deviation between the ascertained total injection quantity and an expected total injection quantity is assumed as the error of the pressure wave compensation and a correction value for the pressure wave compensation is determined therefrom.

Owner:ROBERT BOSCH GMBH

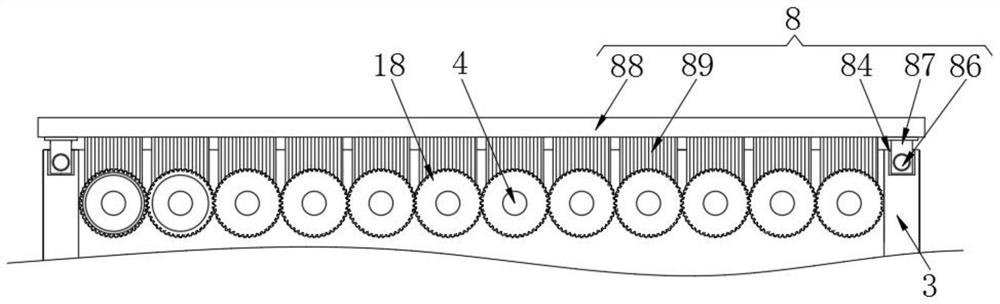

Anti-blocking multi-channel full-automatic chip removal system and chip removal method

InactiveCN113546831AEasy to separateSpeed up emissionsSievingScreeningMechanical engineeringDust collector

The invention discloses an anti-blocking multi-channel full-automatic chip removal system and chip removal method, and relates to technical field of chip removal. The anti-blocking multi-channel full-automatic chip removal system comprises a bottom plate and a filter box fixedly connected to the top of the bottom plate through supporting legs, a filter frame is rotationally connected between the front face and the back face of the inner wall of the filter box through a movable shaft, a fixed frame is fixedly connected to one side of the filter box, one side of each supporting leg is fixedly connected with a dust collector through a supporting frame, and an anti-blocking mechanism is arranged at the top of the filter box. According to the anti-blocking multi-channel full-automatic chip removal system and the chip removal method, hot air is blown downwards through an air outlet nozzle in an anti-blocking mechanism, waste chips blocked in filtering holes can be blown into the filter box, the surfaces of the filtering holes are brushed again in cooperation with the arrangement of a cleaning brush, so that the waste chips are rapidly separated from the filtering holes, blocking is prevented from affecting the subsequent discharging of cooling water, a dust collector is used for uniformly sucking away the waste chips to avoid residues, so that the discharging speed of the waste chips is increased, and the actual use requirements are met.

Owner:浙江吉宝智能装备股份有限公司

Method and device for the pressure wave compensation of consecutive injections in an injection system of an internal combustion engine

InactiveCN102084110AImpact emissionsReduce rated value set pointElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

Owner:ROBERT BOSCH GMBH

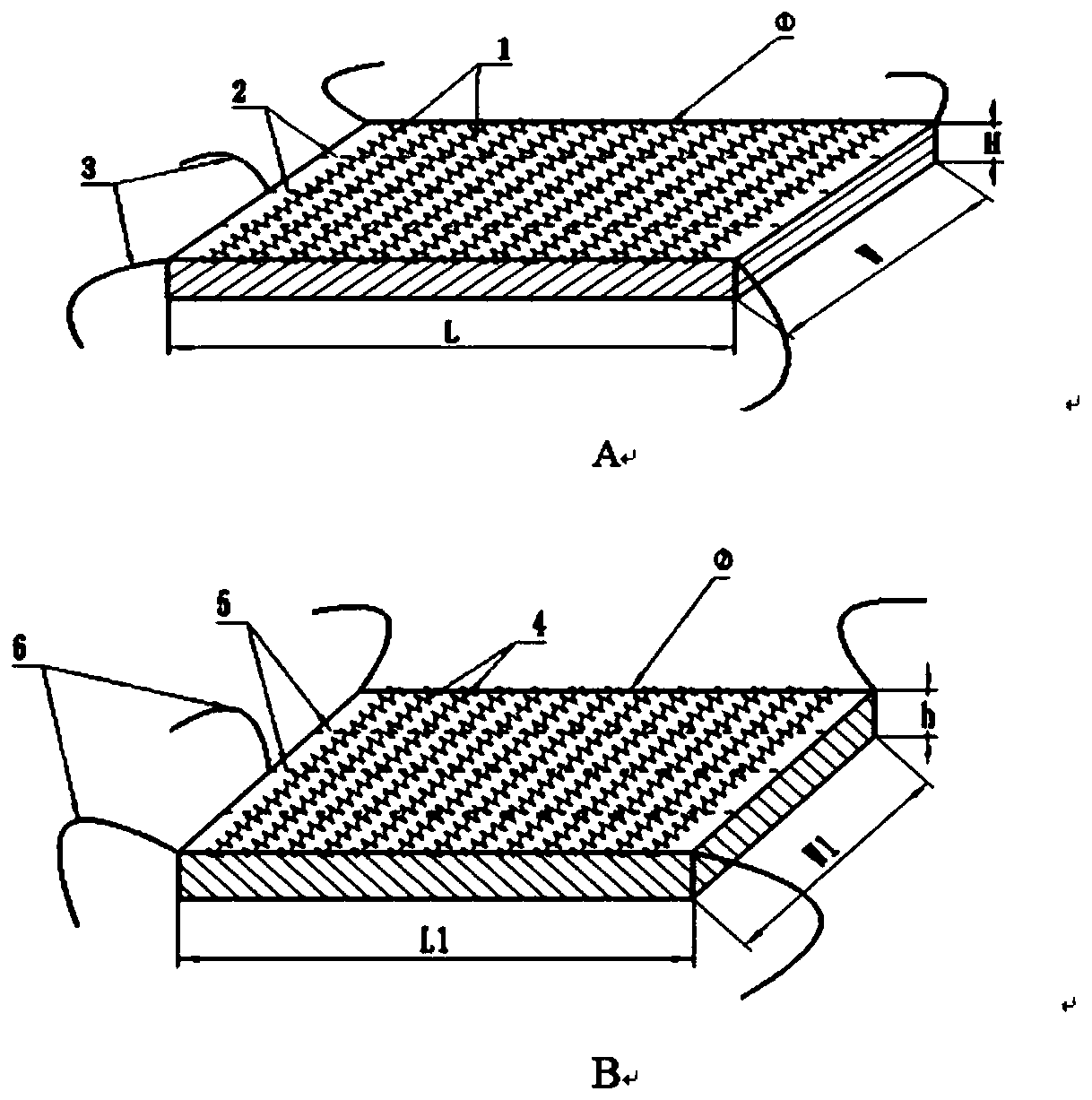

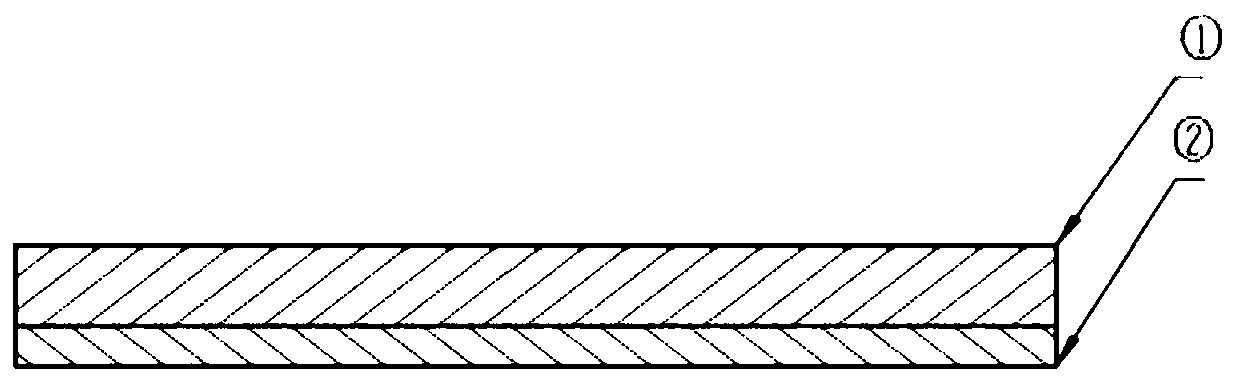

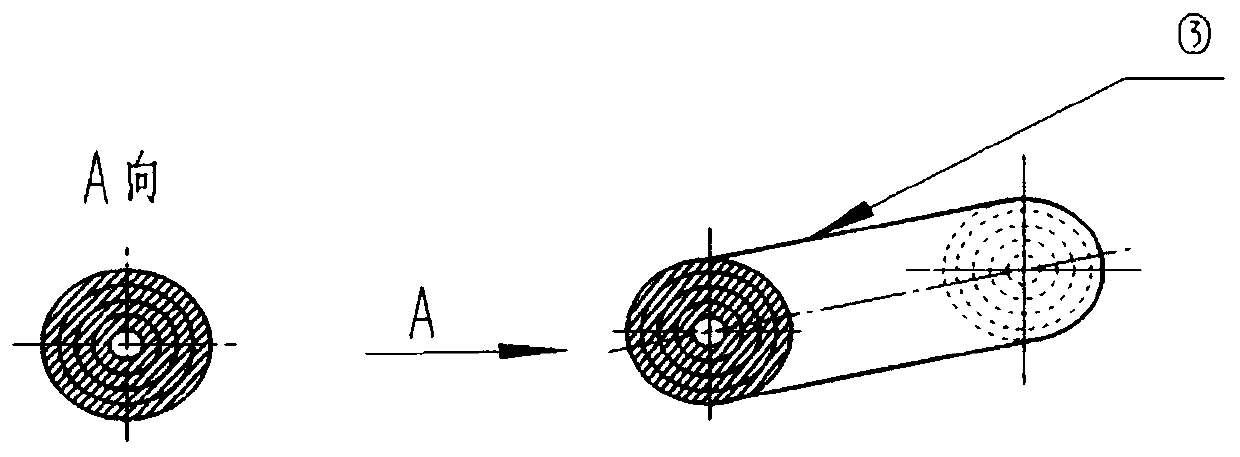

Cattle pen feces absorbing-type straw mattress and application of straw mattress

InactiveCN111053039AAffect healthReduce hygiene problemsAgricultural articlesBio-organic fraction processingMicroorganismAgricultural science

The invention discloses a cattle pen feces absorbing-type straw mattress. The straw mattress comprises a first straw mattress and a second straw mattress laid over the first straw mattress, wherein the first straw mattress is a compact mat braided with wheat straw or corn husks; the second straw mattress is a mat having a multi-layer structure and woven with the wheat straw or the corn husks; thespacing between every two adjacent layers of the structure is set as 1 cm-1.5 cm; and all sides between every two adjacent layers of the second straw mattress are fixedly connected into a whole through the wheat straw or the corn husks. The invention further discloses application of the cattle pen feces absorbing-type straw mattress in a cattle pen; the site sanitation of the cattle pen can be improved obviously, a stink is gone, and the chance that cattle touches feces is reduced; and meanwhile, a sprayed microbial bacterium solution is promoted to propagate dominant bacterial communities toinhibit propagation of harmful bacteria, and thus, the incidence rate of a hoof disease and cattle gastroenteritis can be reduced, and the weight gaining rate of beef cattle and the milk yield of dairy cattle are increased.

Owner:北京宜禾原现代农业科技研究院

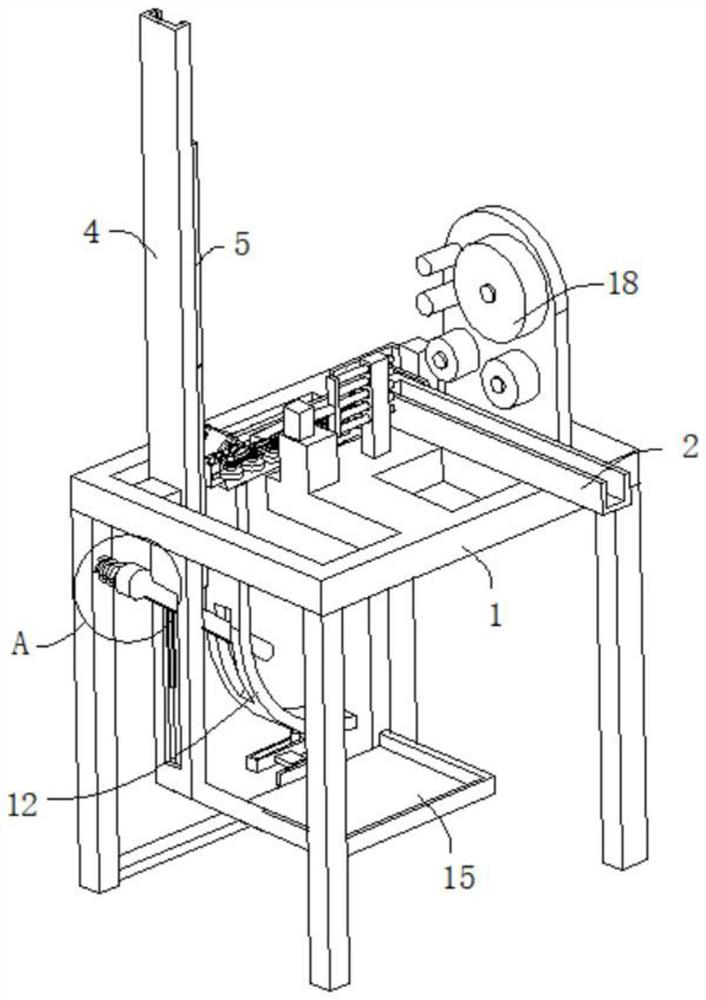

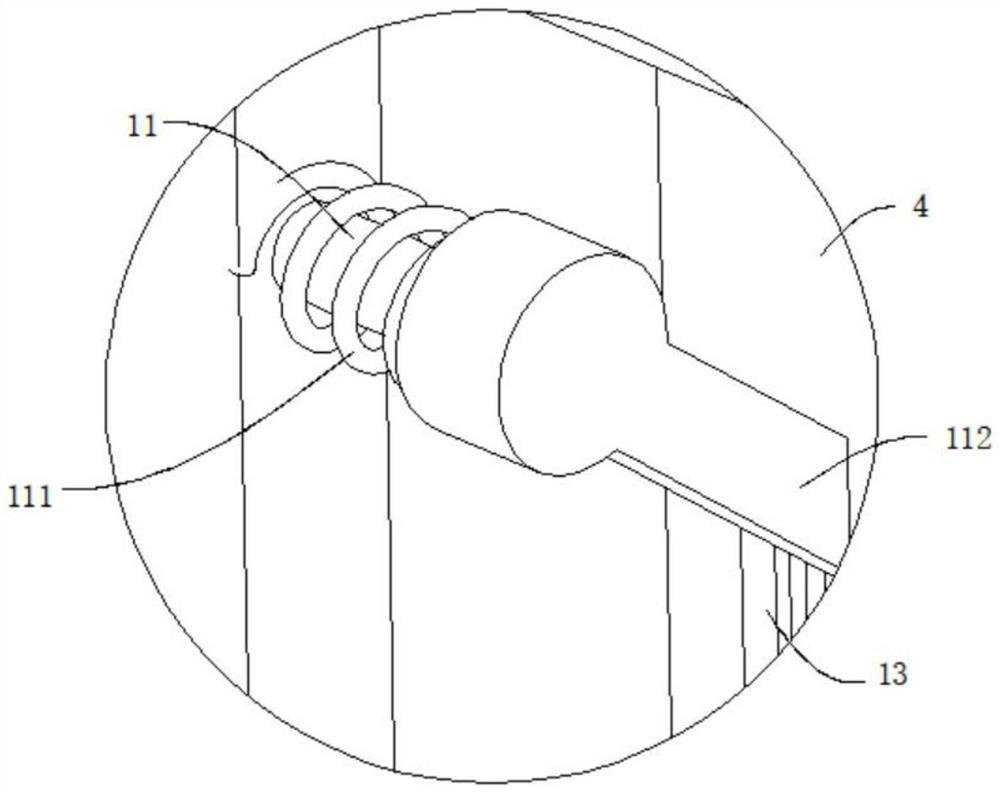

Rail transit air conditioner pipe fitting connector punching device convenient to clean

ActiveCN113909528AImprove securityImprove work efficiencyFeeding apparatusPositioning apparatusPunchingPipe fitting

The invention relates to the technical field of air conditioner pipe fitting machining, in particular to a rail transit air conditioner pipe fitting connector punching device convenient to clean. The rail transit air conditioner pipe fitting connector punching device comprises a mounting cabinet, a positioning conveying device, a punching device, a rapid cleaning device, a collecting hopper and a scrap collecting box; a feeding hole is formed in the mounting cabinet, and a through hole is formed in the bottom of the mounting cabinet; the positioning conveying device is fixedly mounted in the mounting cabinet, and the input end of the positioning conveying device is in butt joint with the feeding hole of the mounting cabinet; the punching device is fixedly mounted at the top of the mounting cabinet; the rapid cleaning device is fixedly mounted at the top of the mounting cabinet, and the working end of the rapid cleaning device is arranged at the working end of the punching device; the collecting hopper is fixedly mounted at the bottom of the mounting cabinet; and the scrap collecting box is arranged below the output end of the collecting hopper. The production safety and the working efficiency are effectively improved.

Owner:JIAXING MASTER PLUMBING

Solid-liquid separation filter tank for processing cleaning wastewater

InactiveCN112843827ARealize solid-liquid separationKeep filter operationStationary filtering element filtersWastewaterMechanical engineering

A solid-liquid separation filter box for processing cleaning wastewater comprises a box body; a filter screen cover is fixedly connected to the interior of the box body, a water inlet is formed in the top of the box body, the bottom end of the water inlet extends into the filter screen cover, a water outlet is formed in one side of the box body, and a discharge port is formed in the bottom of the box body; and a material guiding mechanism is arranged on the periphery of the discharging port, solid chippings are guided into the discharging port, a shielding mechanism is arranged above the material guiding mechanism, and supporting mechanisms are fixedly connected to the four corners of the bottom of the box body and used for supporting and limiting the box body and the material guiding mechanism. Through cooperation of the filter screen cover and the box body, chippings in the cleaning wastewater can be intercepted, so that solid-liquid separation of the cleaning wastewater is realized; in addition, filtered liquid and solid are discharged through different outlets and are prevented from being mixed again, the intercepted chippings can be automatically discharged out of the box body after being accumulated to a certain height, and manual regular cleaning is not needed.

Owner:马鞍山睿诚科技信息咨询有限公司

Lighter paper packaging equipment with automatic feeding and discharging functions

ActiveCN113650842AReduce laborImprove work efficiencyPackaging machinesManufacturing engineeringElectrical and Electronics engineering

The invention discloses lighter paper packaging equipment with automatic feeding and discharging functions, and belongs to the technical field of lighter production. The lighter paper packaging equipment with the automatic feeding and discharging functions comprises a rack, a paper packaging device used for packaging lighters is arranged on the outer wall of the rack, the two sides of the paper packaging device are connected with a feeding channel and a discharging channel correspondingly, a conveying belt is arranged in the feeding channel, a conveying mechanism is arranged on the outer wall of the discharging channel, the inner wall of the rack is connected with a discharge plate through a connecting plate, the inner wall of the discharge plate is movably connected with multiple containing plates, evenly-distributed containing grooves used for containing lighters are formed in the outer walls of the containing plates, a feed mechanism is arranged on the outer wall of the discharging channel, and limiting holes cooperating with the feed mechanism are dug in the outer walls of the containing plates. According to the lighter paper packaging equipment, automation of feeding and discharging of lighters in the paper packaging process is conveniently achieved, discharged lighters are automatically stacked in order, the labor amount of workers is reduced, and the working efficiency of lighter production is improved.

Owner:HUNAN DONGYI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com