Method and device for the pressure wave compensation of consecutive injections in an injection system of an internal combustion engine

一种喷射系统、内燃机的技术,应用在燃料喷射控制、内燃活塞发动机、燃烧发动机等方向,能够解决时间上第二预喷射量精确度公差要求不够等问题,达到改进效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

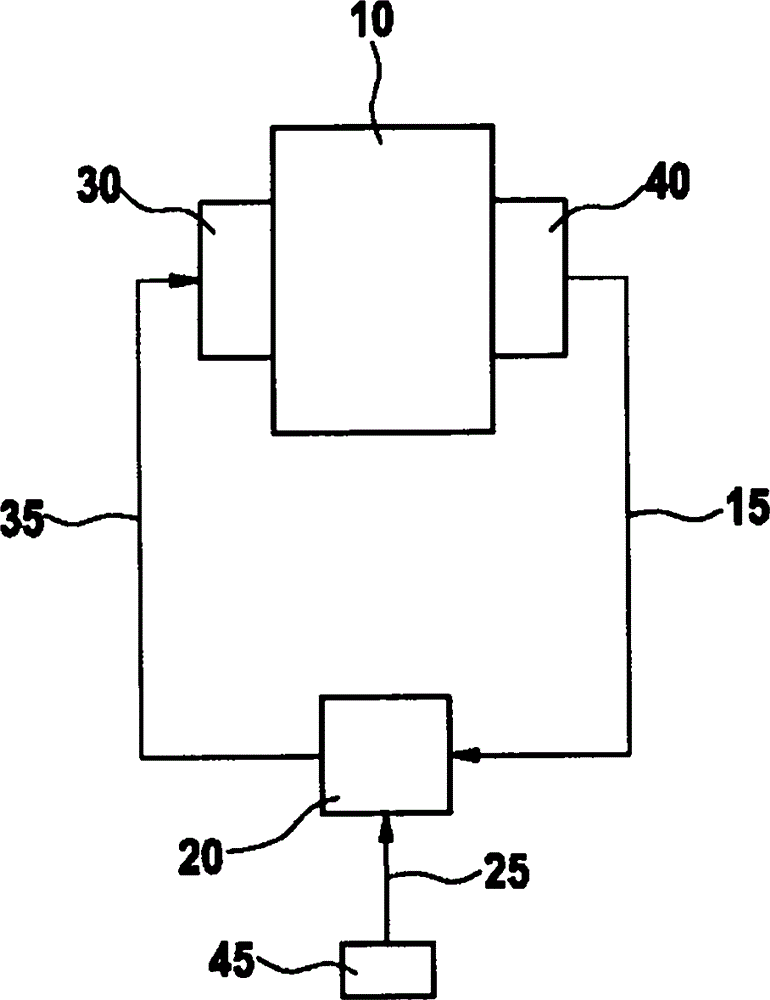

[0018] FIG. 1 shows a block diagram of the main elements of a fuel metering system of an internal combustion engine previously known from DE 199 45 618 A1. Internal combustion engine 10 receives a specific fuel quantity from fuel metering unit 30 at a specific time. Various sensors 40 detect measured values 15 characterizing the operating state of the internal combustion engine and transmit them to the control unit 20 . In addition, different output signals 25 of further sensors 45 are transmitted to the control device 20 . Detected measured value 15 characterizes a state of the fuel metering unit, such as the driver's desire. On the basis of these measured values 15 and further variables 25 , control device 20 calculates a trigger pulse 35 , which is applied to fuel metering unit 30 .

[0019] The internal combustion engine assumed here is preferably a direct-injection and / or self-ignition internal combustion engine. The fuel metering unit 30 can be designed in differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com