Granulated and enteric coated composite trace elements and preparation method thereof

A compound trace element, enteric coating technology, applied in the fields of additional food elements, food science, animal feed, etc., can solve the problems of high cost, slow granulation, unevenness, etc., to reduce usage, promote fast, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

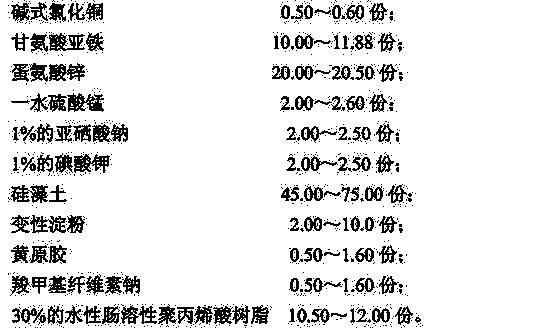

[0024] 1. Weigh raw materials:

[0025]

[0026] All the above-mentioned raw materials can be purchased in the raw material market.

[0027] Second, the operation process steps are as follows:

[0028] (1) Humidification and mixing: basic copper chloride, ferrous glycinate, zinc methionine, manganese sulfate monohydrate, 1% sodium selenite, 1% potassium iodate, diatomaceous earth, modified starch, xanthan gum 1. Carboxymethylcellulose sodium (CMC) is sprayed into 150 kg of water according to the above mass ratio, and mixed for 15 minutes;

[0029] (2) Extrusion into granules: Put the above-mentioned humidified and mixed materials into the swing granulator, and use diatomaceous earth, modified starch, xanthan gum, sodium carboxymethyl cellulose (CMC) to absorb water to produce viscosity and self-hardening Features, the mixture is extruded into granules for the first time through the swing granulator;

[0030] (3) Enteric coating: Put the material extruded into granules fo...

Embodiment 2

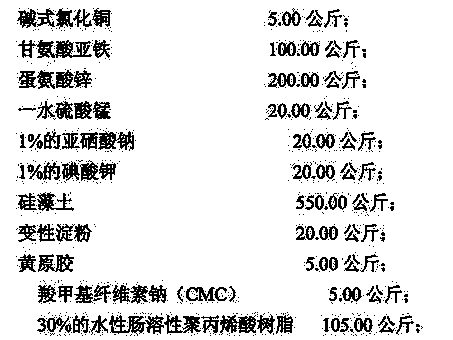

[0036] 1. Weigh raw materials:

[0037]

[0038] All the above-mentioned raw materials can be purchased in the raw material market.

[0039] Second, the operation process steps are as follows:

[0040] (1) Humidification and mixing: basic copper chloride, ferrous glycinate, zinc methionine, manganese sulfate monohydrate, 1% sodium selenite, 1% potassium iodate, diatomaceous earth, modified starch, xanthan gum 1. Carboxymethylcellulose sodium (CMC) is sprayed into 135 kg of water according to the above mass ratio, and mixed for 15 minutes;

[0041] (2) Extrusion into granules: Put the above-mentioned humidified and mixed materials into the swing granulator, and use diatomaceous earth, modified starch, xanthan gum, sodium carboxymethyl cellulose (CMC) to absorb water to produce viscosity and self-hardening Features, the mixture is extruded into granules for the first time through the swing granulator;

[0042] (3) Enteric coating: put the material extruded into granules fo...

Embodiment 3

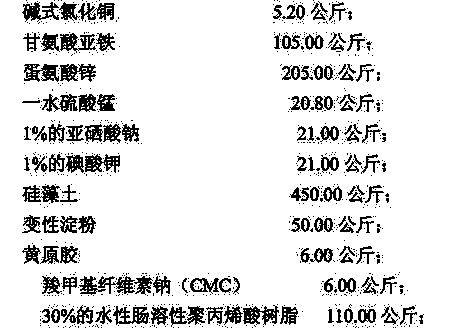

[0048] 1. Weigh raw materials:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com