Contaminated soil remediation system

A technology for remediating systems and polluted soil, applied in the restoration of polluted soil, etc., can solve the problems of inability to separate inorganic substances, waste of energy, and high production costs, and achieve the goal of avoiding pollution and transshipment costs, broad market prospects, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

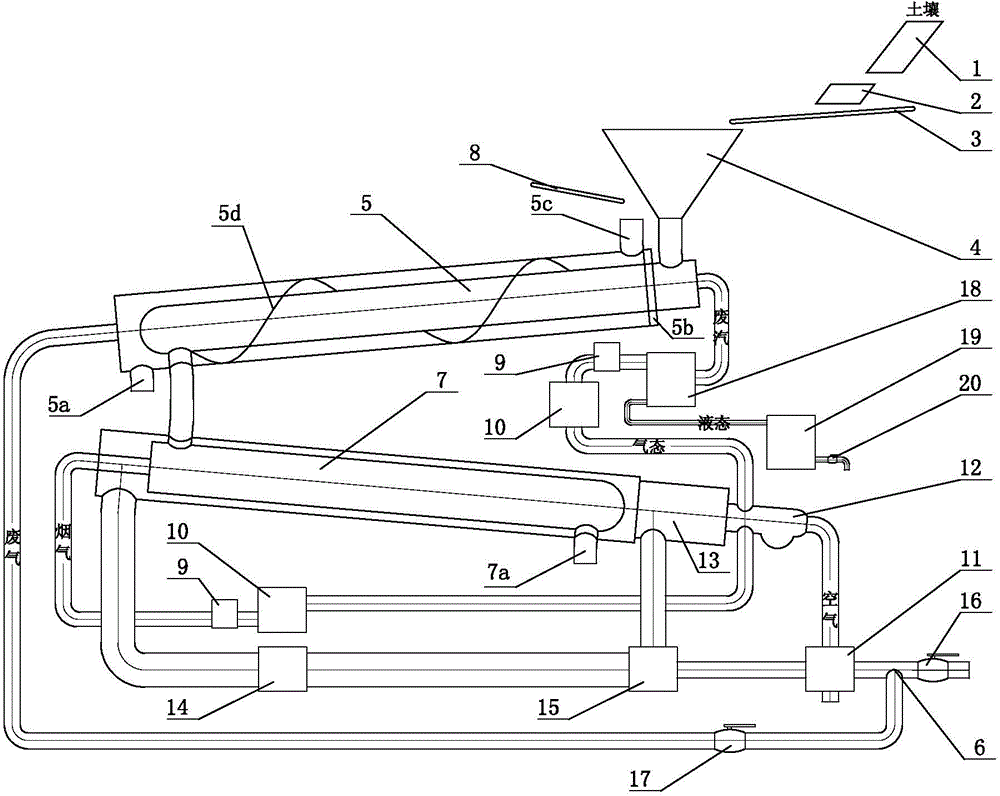

[0027] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0028] like figure 1 As shown, a contaminated soil remediation system consists of a sorter 1, a crusher 2, a second conveyor belt 3, a feed bin 4, a waste heat rotary kiln 5, a tee pipe 6, a thermal desorption rotary kiln 7, and a first conveyor belt 8. Fan 9, buffer tank 10, air preheater 11, burner 12, combustion chamber 13, induced draft fan 14, regulating distributor 15, exhaust valve 16, smoke volume regulating valve 17, condensation separator 18, waste liquid tank 19. The drain valve 20 and other components.

[0029] Both the waste heat rotary kiln 5 and the heat desorption rotary kiln 7 are double-layered, including an inner tank and an outer shell, and the space between the inner tank and the outer shell is large enough. The feed end of the waste heat rotary kiln 5 and the heat desorption rotary kiln 7 are higher than the discharge end, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com