Slurry separation equipment

A slurry separation and equipment technology, applied in filtration separation, separation methods, and sediment separation by centrifugal force, etc., can solve the problems of affecting the amount of sand discharge, reducing the service life of the device, and wearing blades, so as to achieve a large amount of sand discharge and prevent clogging. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

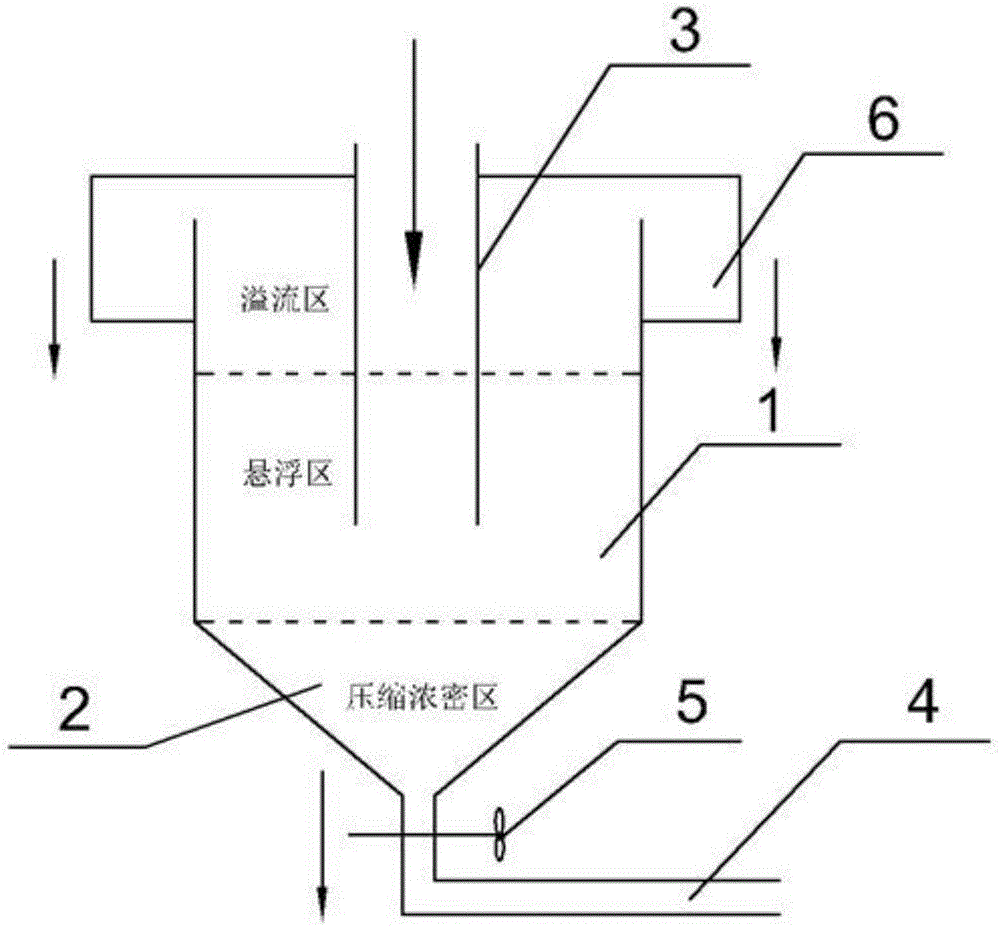

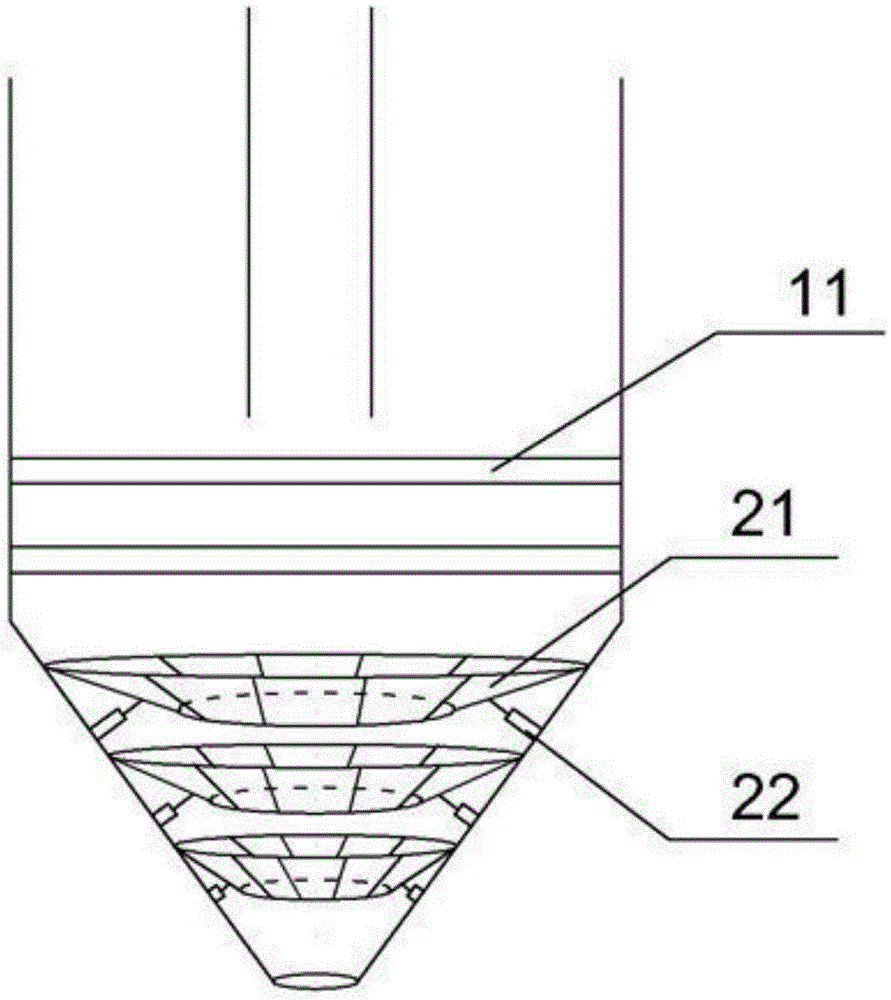

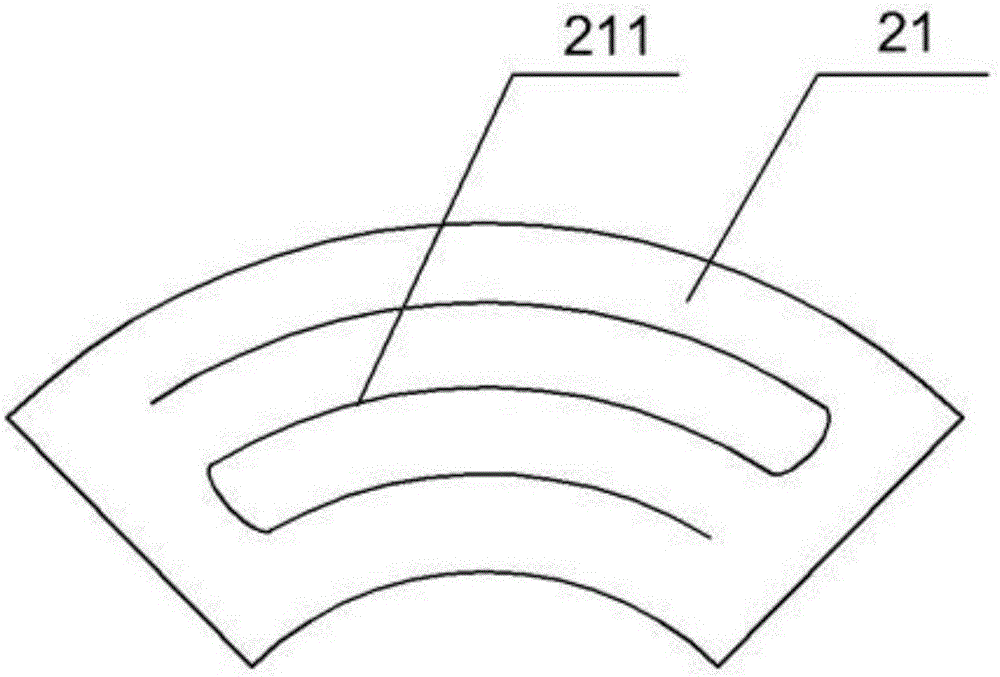

[0026] like Figures 1 to 3 As shown, the present invention provides a slurry separation device, which is integrally formed by a cylindrical first part 1 and a conical second part 2 with the bottom surface facing upwards and the apex facing downwards. The feeding cylinder 3 extends into the first part 1 to introduce the slurry. The interior of the first part 1 and the second part 2 forms a through-space for holding the slurry, and the bottom of the second part 2 is provided with a slurry outlet for leading the separated thick slurry, and communicates with the slurry outlet. The slurry discharge pipe 4 and the valve 5 connecting / disconnecting the slurry discharge pipe 4, wherein, the diameter ratio of the feed cylinder 3 to the slurry discharge pipe 4 is 4-6:1. By designing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com