Anti-blocking device for injection molding machine nozzle and mould feed points

A technology for injection molding machines and molds, which is applied in the field of devices for preventing nozzle and mold entry points from being clogged. It can solve problems such as high cost, difficulty in realization, and limitation, and achieve small injection flow and speed, avoid downtime for maintenance, and increase circulation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

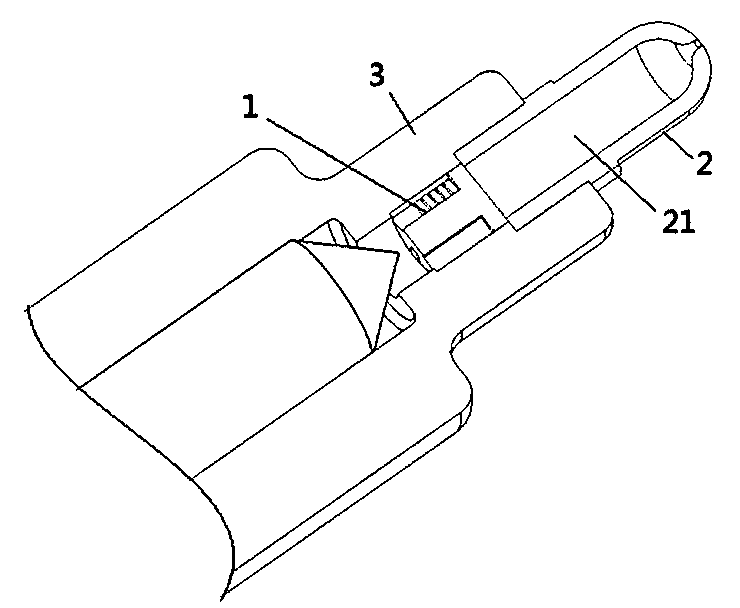

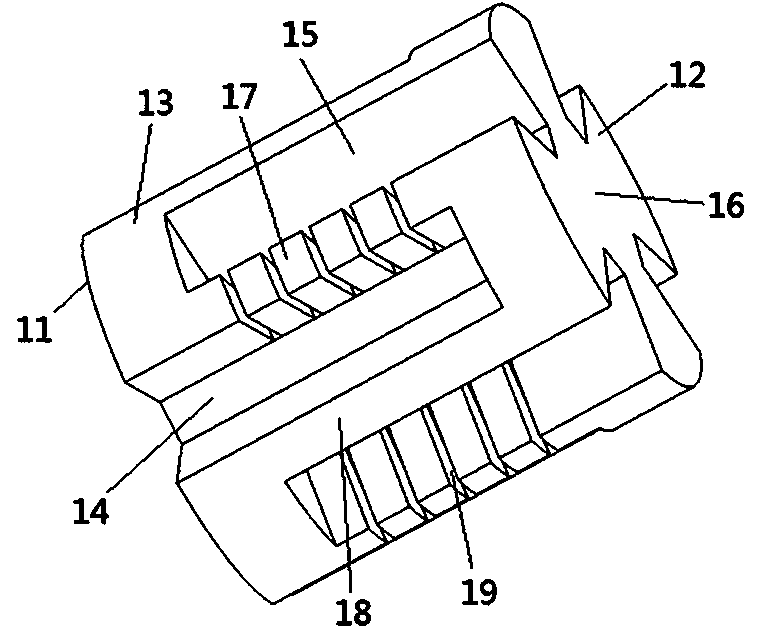

[0018] Embodiment: an injection molding machine nozzle and a mold entry point anti-blocking device, the rear end of the center hole 21 of the injection molding machine nozzle 2 or the part of the injection molding machine material tube 3 located behind the injection molding machine nozzle is equipped with a filter column 1, so The filter column has a relative first bottom surface 11, a second bottom surface 12, and a side surface 13. On the side surface 13 of the filter column, several feeding grooves 14 and some discharging grooves 15 are provided, and one end of the feeding groove 14 is opened on the The first bottom surface 11 of the filter column extends from the first bottom surface 11 of the filter column to the second bottom surface 12 of the filter column, and the second bottom surface 12 of the filter column is closed and opposite to one end of the feed tank The other end of the feed tank, one side of the feed tank 14 opens to the side 13 of the filter column and exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com