Scrubber integrated system capable of circularly filtering and recycling sewage

A technology of sewage circulation and integrated system, applied in the direction of cleaning carpets, floors, machine parts, etc., can solve the problems of poor user experience of roller components, easy storage of dirt and scale, and large water consumption, etc., to improve the use experience. Sensation, ingenious structure design, safe and non-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

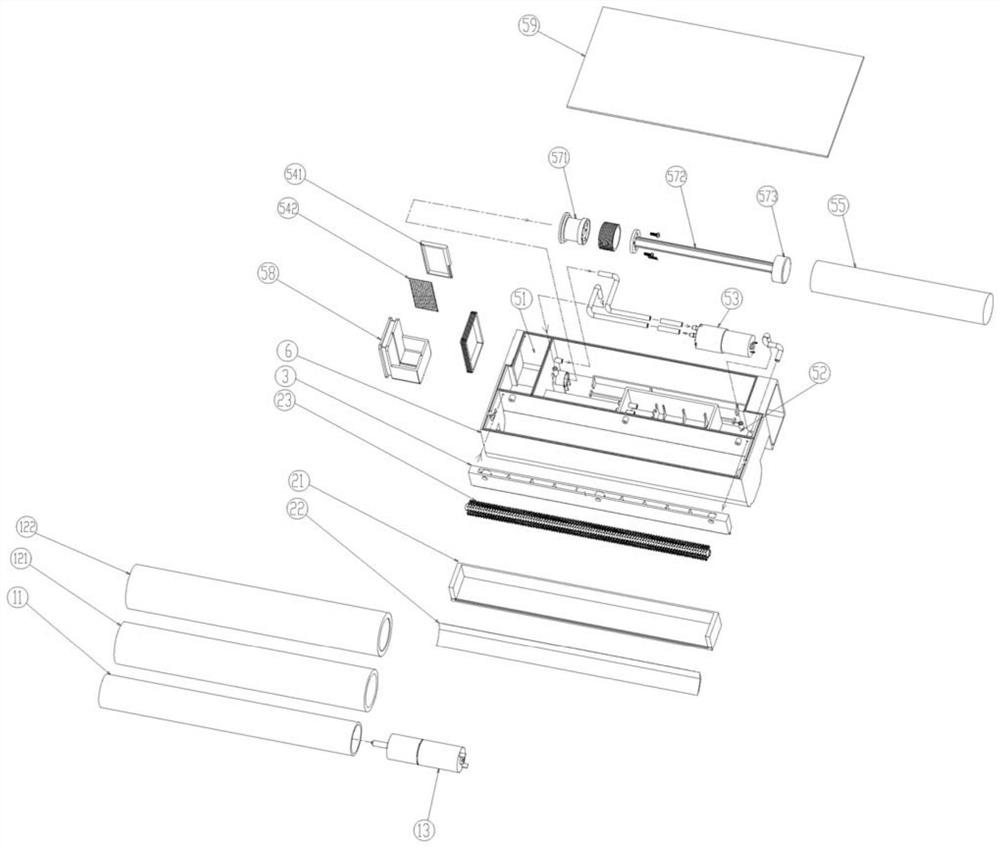

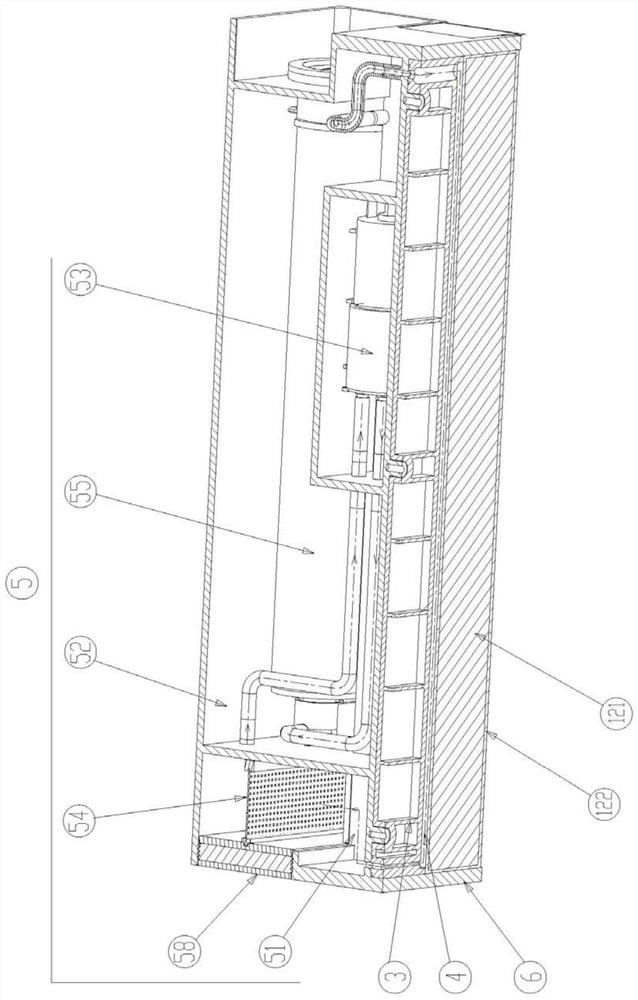

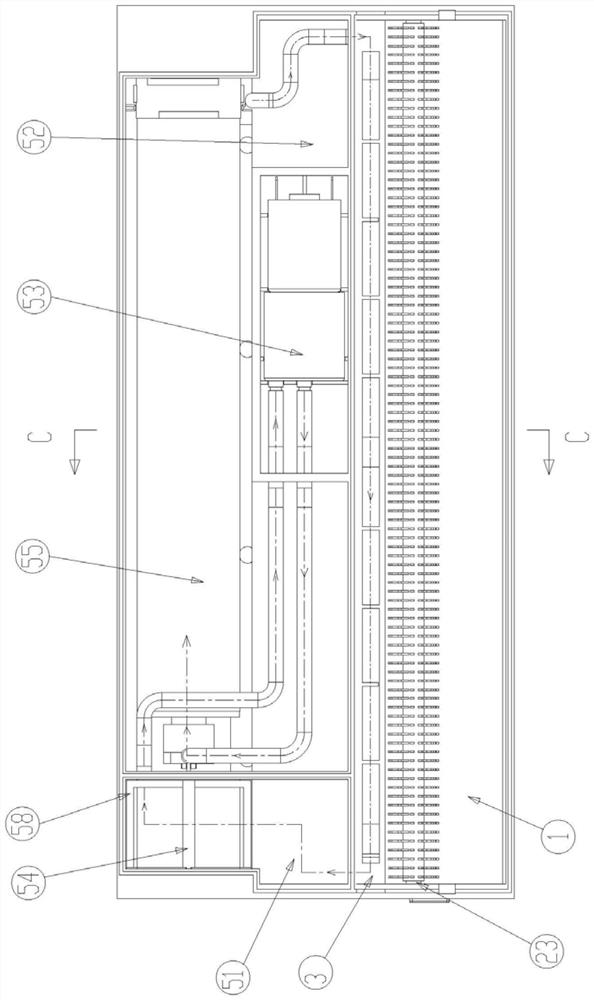

[0051] like Figure 1~4 The floor washing machine integrated system that can carry out recycling, filtration and recovery of sewage includes a housing 6 in which a drum assembly 1, a dust collection assembly 2, a water tank 3 and a water circulation assembly 5 are arranged. The assembly 1 is arranged at the front end of the housing 6 to clean up the garbage and collect it into the dust collection assembly 2. The water tank 3 is in contact with the drum assembly 1, and a closed chamber for water to pass through is formed between the water tank 3 and the drum assembly 1. 4. The airtight chamber 4 communicates with the water circulation assembly 5 through the liquid inlet pipe and the liquid outlet pipe respectively, and the sewage flowing out of the liquid outlet pipe enters the water circulation assembly 5 for purification and then flows into the airtight chamber 5 through the liquid inlet pipe again to realize water recycling;

[0052] The roller assembly 1 includes a roller ...

Embodiment 2

[0075] The difference between embodiment 2 and embodiment 1 is that the sewage tank 51 is not provided, and the sewage filtered by the filter device 54 can be pumped into the cavity 56 under the action of the pump assembly 53 . The filtering device 54 can be multiple filter screens 542 arranged in the water inlet pipeline of the pump assembly 53 to block a large amount of garbage and prevent the pump assembly 53 from being blocked.

Embodiment 3

[0077] The difference between embodiment 3 and embodiment 1 is that the sewage tank 51 is not provided, and the sewage filtered by the filter device 54 can be pumped into the clean water tank 52 outside the cavity 56 under the action of the pump assembly 53. Under the action of positive pressure, it flows from the outside of the cavity 56 to the inside of the cavity 56 for filtration, and under the action of water pressure, the large particle aggregates formed by polymerization settle on the outer peripheral surface of the purification filter element 55, and a small amount settle on the outer peripheral surface of the purification filter element 55. In the clean water tank 52, after using for a period of time, the user can manually remove the dirt layer on the outer peripheral surface of the purification filter element 55 and the inner wall of the water collection tank 52. And in this embodiment, no drawing assembly is arranged in the cavity 56 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com