Magnetic well device for purifying high-temperature liquid metal

A technology of liquid metal and magnetic trap, which is applied in the field of energy-saving high-gradient magnetic purification devices to achieve reasonable layout, increase the contact area, and reduce the risk of screen collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

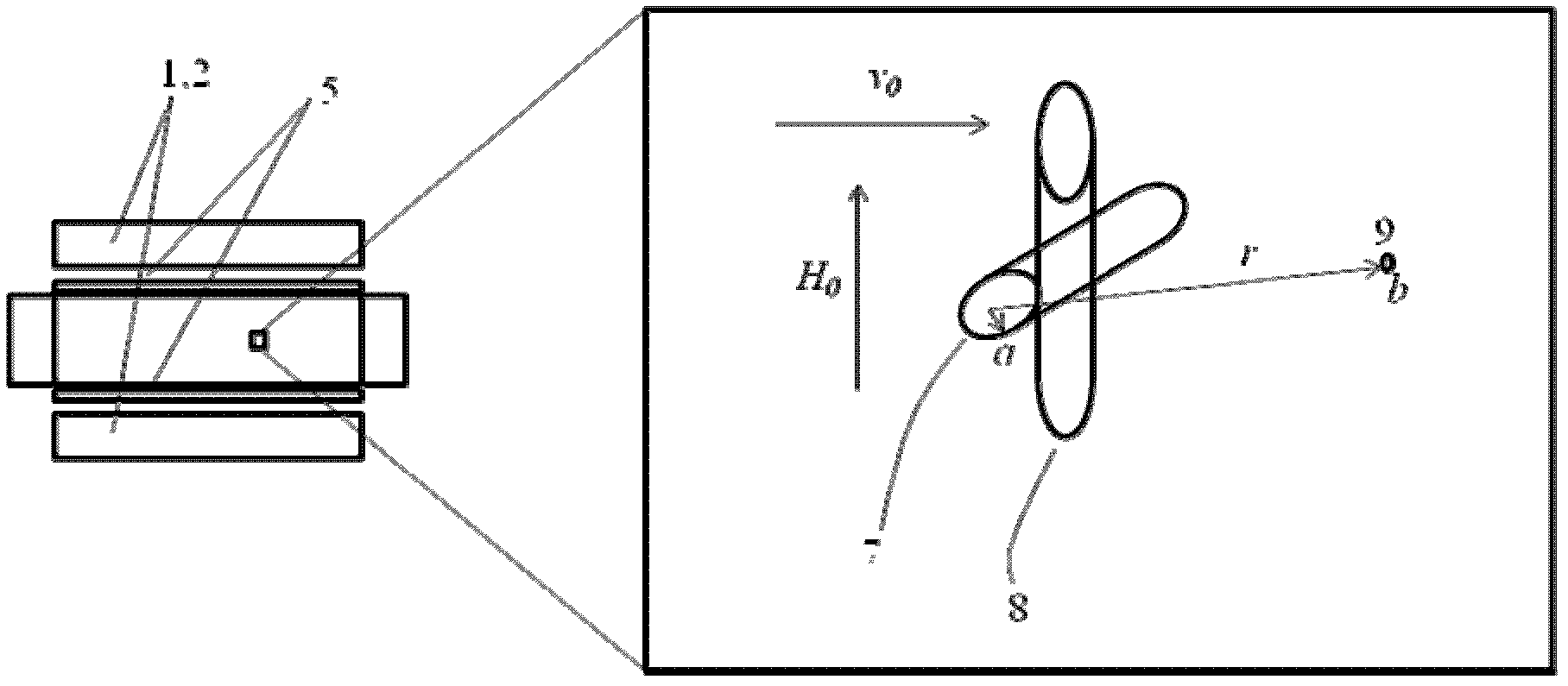

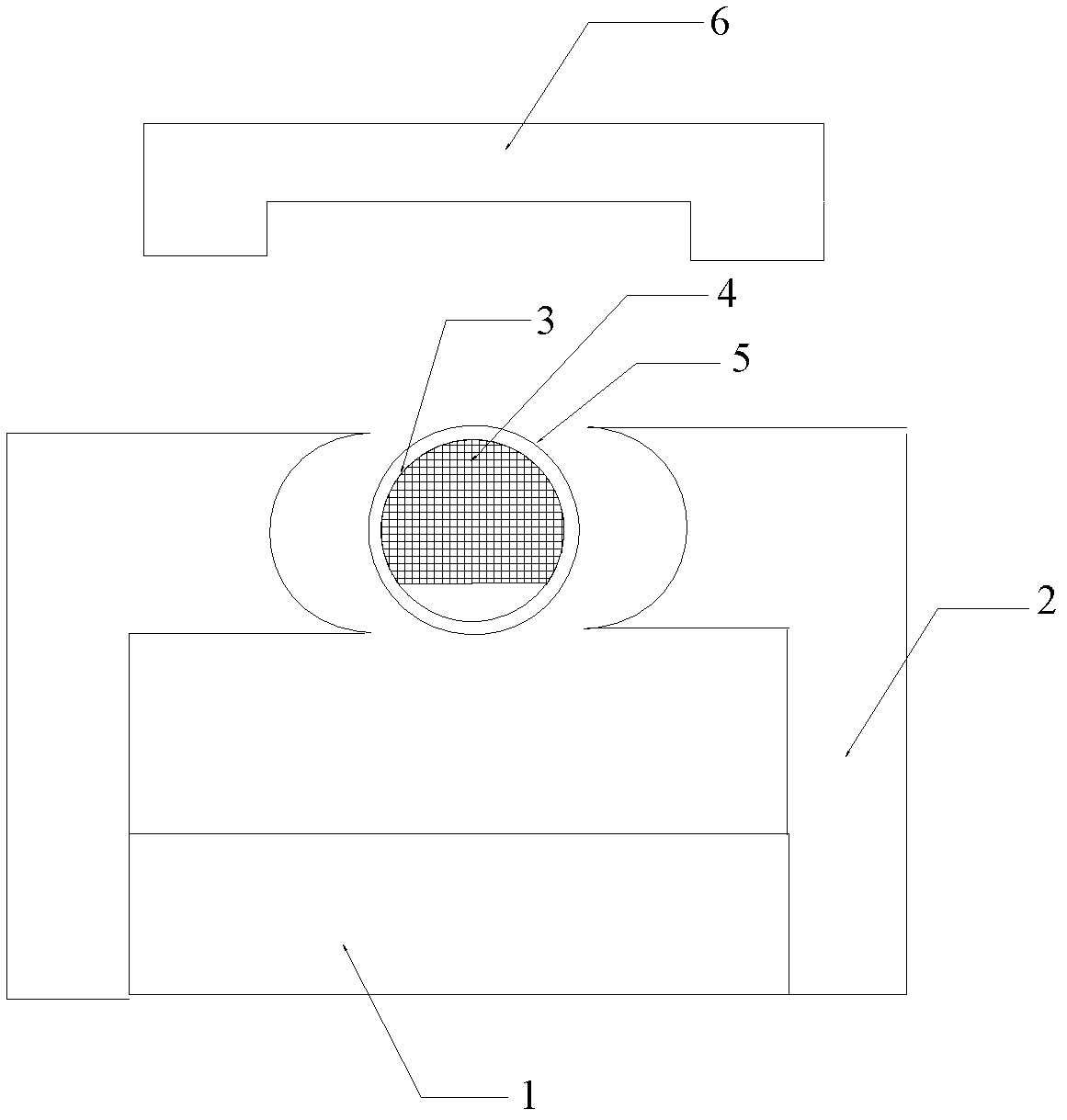

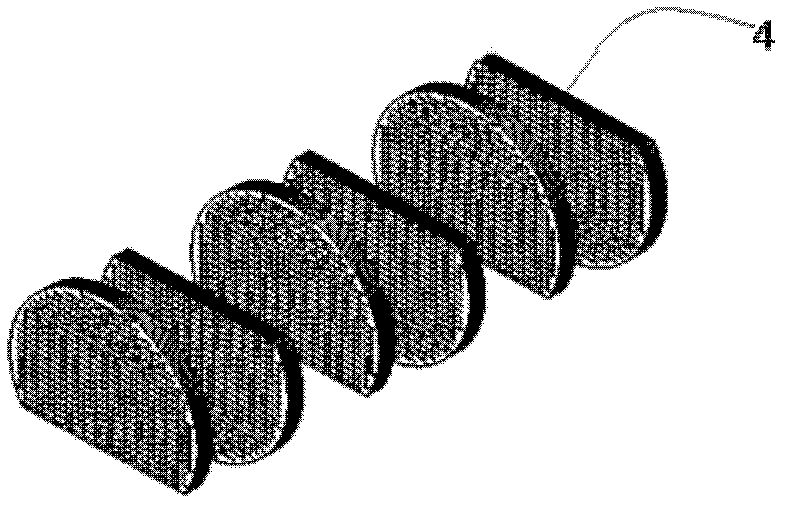

[0027] Depend on Figure 1-5 It can be seen that the magnetic trap device for purifying liquid metal at high temperature (usually >300° C.) according to the present invention includes: a permanent magnet 1 , a yoke 2 , a sorting space 3 and an armature 6 . Depend on figure 2 It can be seen that the permanent magnet 1 and the yoke 2 form a magnetic circuit with an air gap, and the sorting space 3 is located in the air gap; image 3 It can be seen that in the sorting space 3, the arched magnetic-gathering medium screen 4 with an arc length larger than a semicircle is staggered; Figure 4 It can be seen that what constitutes the magnetic-gathering medium screen 4 is magnetic-conductive stainless steel wool 7 and non-magnetic stainless steel wire 8, and then by figure 1 It can be seen that the magnetic field direction H 0 , liquid metal flow direction v 0 And magnetic stainless steel wool 7 three mutually perpendicular, can produce high magnetic field gradient on magnetic sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com