Aluminum profile chromate-free passivation agent

A chrome-free passivation agent and aluminum profile technology, applied in the direction of metal material coating process, can solve the problems of high processing cost, difficult control, and no inclusion, etc., and achieve the effect of improving anti-rust performance and good industrialization prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

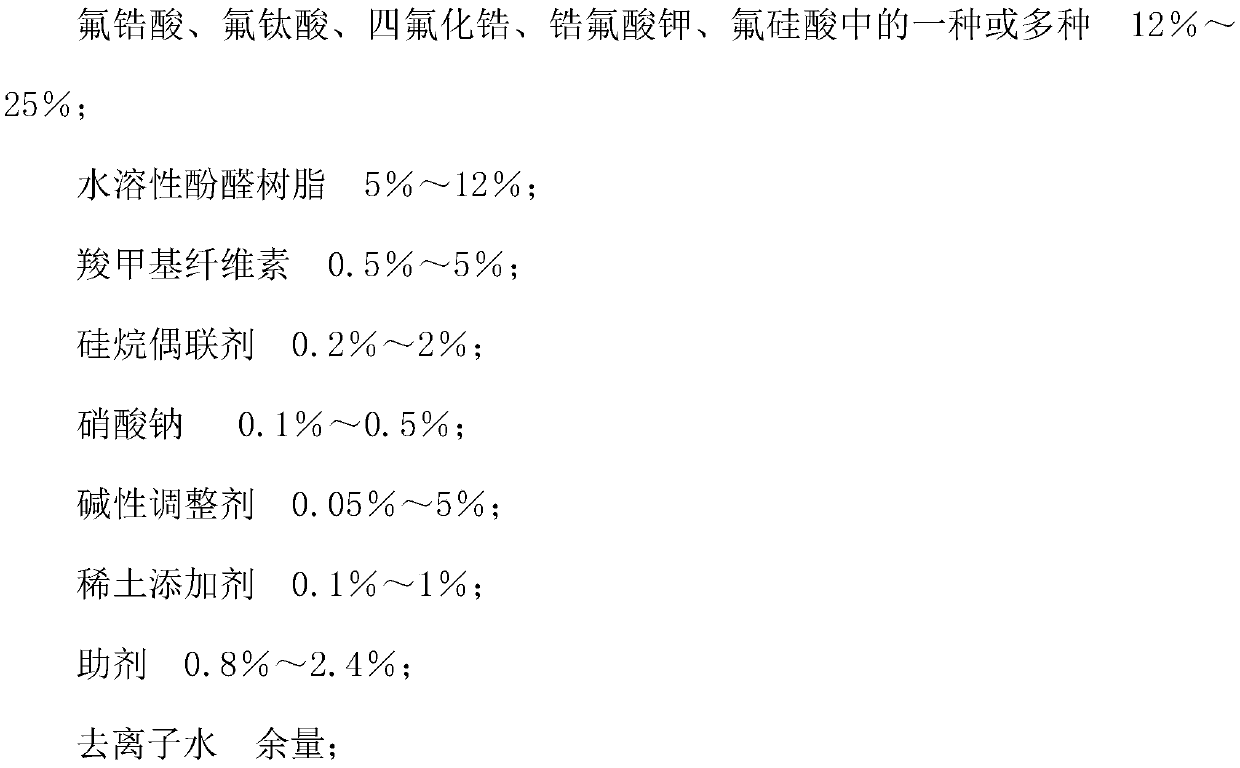

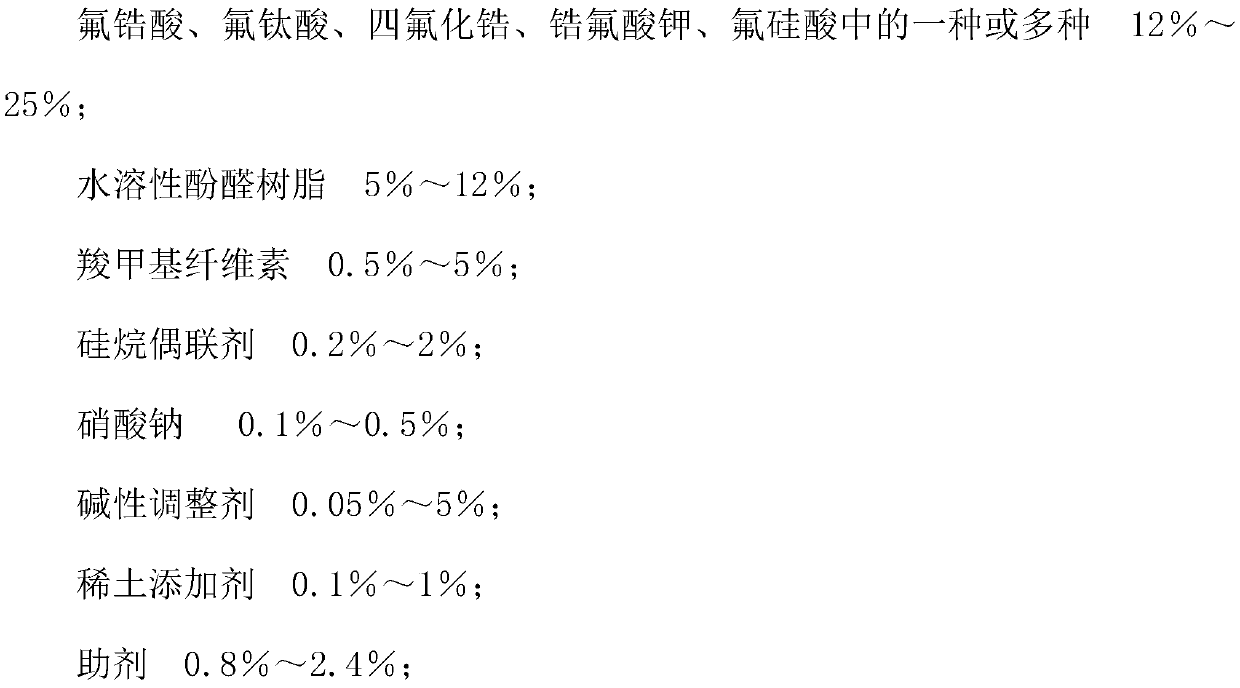

[0037] Embodiment 1, a kind of chrome-free passivation surface treatment agent that is used for the surface treatment of aluminum material before painting, comprises following component by weight percentage:

[0038]

[0039] Wherein the concentration of the carboxymethyl cellulose is 85%, and the average molecular weight is 1.1×106; the pH value of the above composition is adjusted to 3.8 with sodium hydroxide. The OP-10 is produced by Lushun Chemical Factory, and its main component is alkylphenol polyoxyethylene ether.

[0040] Clean the sample plate, after cleaning and drying, soak in the above metal surface treatment agent for 3 minutes; take it out, dry it with hot air, spray paint, and measure the coating performance. The test results of the sample plate are shown in Table 2.

Embodiment 2

[0041]Embodiment 2, repeat embodiment 1 by each component content specified in table 1, but the concentration of described carboxymethyl cellulose is 85%, average molecular weight 1.1 * 106; Regulate above-mentioned composition pH value with potassium hydroxide 4.0.

[0042] The experimental results are shown in Table 2.

Embodiment 3

[0043] Embodiment 3, repeat embodiment 1 by each component content specified in table 1, but the concentration of described carboxymethyl cellulose is 75%, average molecular weight 1.3 * 106; Regulate above-mentioned composition pH value with potassium hydroxide 4.8.

[0044] The experimental results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com