Insulating shell of switch cabinet

A technology for insulating shells and switch cabinets, applied in the field of insulating shells, can solve the problems of low structural strength, poor insulation effect, and poor anti-aging effect of insulating shells, and achieve good insulation effects, stable chemical properties, The effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

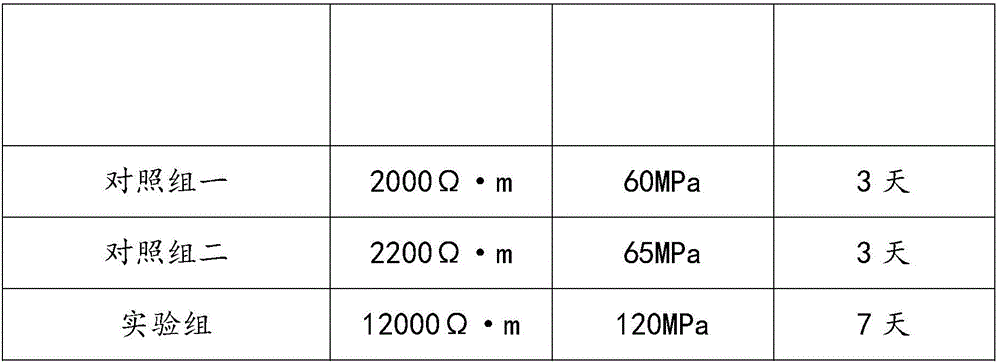

Embodiment 1

[0021] An insulating shell of a switch cabinet, made of the following raw materials in parts by weight, including 25 parts of glass fiber, 6 parts of silicon dioxide, 9 parts of fiber cotton, 20 parts of polycarbonate resin, 7 parts of polyurethane, and 2 parts of polypropylene , 16 parts of poly-1-butene, 2 parts of boron oxide, 7 parts of calcium carbonate, 8 parts of barium sulfate, 6 parts of aramid fiber, 2 parts of molybdenum disulfide, 4 parts of dibutyl phthalate, phthalate 13 parts of diisobutyl diformate, 7 parts of sodium citrate, 3 parts of zirconium tetrafluoride, 11 parts of ethyl acetate, 6 parts of butyl methacrylate and 18 parts of N-phenyl-β-naphthylamine.

[0022] A method for preparing an insulating shell of a switchgear, comprising the following steps:

[0023] 1) Mix 25 parts of glass fiber, 6 parts of silicon dioxide, 9 parts of fiber cotton, 20 parts of polycarbonate resin, 7 parts of polyurethane, 2 parts of polypropylene, 16 parts of poly-1-butene, 2 ...

Embodiment 2

[0031] An insulating shell of a switchgear is made of the following raw materials in parts by weight, including 26.5 parts of glass fiber, 10 parts of silicon dioxide, 10.5 parts of fiber cotton, 22 parts of polycarbonate resin, 10 parts of polyurethane, and 5 parts of polypropylene , 18 parts of poly-1-butene, 3 parts of boron oxide, 7.5 parts of calcium carbonate, 9 parts of barium sulfate, 10 parts of aramid fiber, 5 parts of molybdenum disulfide, 6 parts of dibutyl phthalate, phthalate 14 parts of diisobutyl diformate, 8 parts of sodium citrate, 5.5 parts of zirconium tetrafluoride, 12.5 parts of ethyl acetate, 9 parts of butyl methacrylate and 19 parts of N-phenyl-β-naphthylamine.

[0032] A method for preparing an insulating shell of a switchgear, comprising the following steps:

[0033] 1) Mix 26.5 parts of glass fiber, 10 parts of silicon dioxide, 10.5 parts of fiber cotton, 22 parts of polycarbonate resin, 10 parts of polyurethane, 5 parts of polypropylene, 18 parts o...

Embodiment 3

[0041] An insulating shell of a switch cabinet is made of the following raw materials in parts by weight, including 28 parts of glass fiber, 14 parts of silicon dioxide, 12 parts of fiber cotton, 24 parts of polycarbonate resin, 13 parts of polyurethane, and 8 parts of polypropylene , 20 parts of poly-1-butene, 4 parts of boron oxide, 8 parts of calcium carbonate, 10 parts of barium sulfate, 14 parts of aramid fiber, 8 parts of molybdenum disulfide, 8 parts of dibutyl phthalate, phthalate 15 parts of diisobutyl diformate, 9 parts of sodium citrate, 8 parts of zirconium tetrafluoride, 14 parts of ethyl acetate, 12 parts of butyl methacrylate and 20 parts of N-phenyl-β-naphthylamine.

[0042] A method for preparing an insulating shell of a switchgear, comprising the following steps:

[0043] 1) Mix 28 parts of glass fiber, 14 parts of silicon dioxide, 12 parts of fiber cotton, 24 parts of polycarbonate resin, 13 parts of polyurethane, 8 parts of polypropylene, 20 parts of poly-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com